Silver-containing film etching liquid composition and conductive pattern forming method using the same

A conductive pattern and composition technology, applied in the field of silver-containing film etching solution composition, can solve the problems of etching rate difference, residue, difficulty in adjusting etching rate, etc., and achieve the effect of inhibiting re-precipitation and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

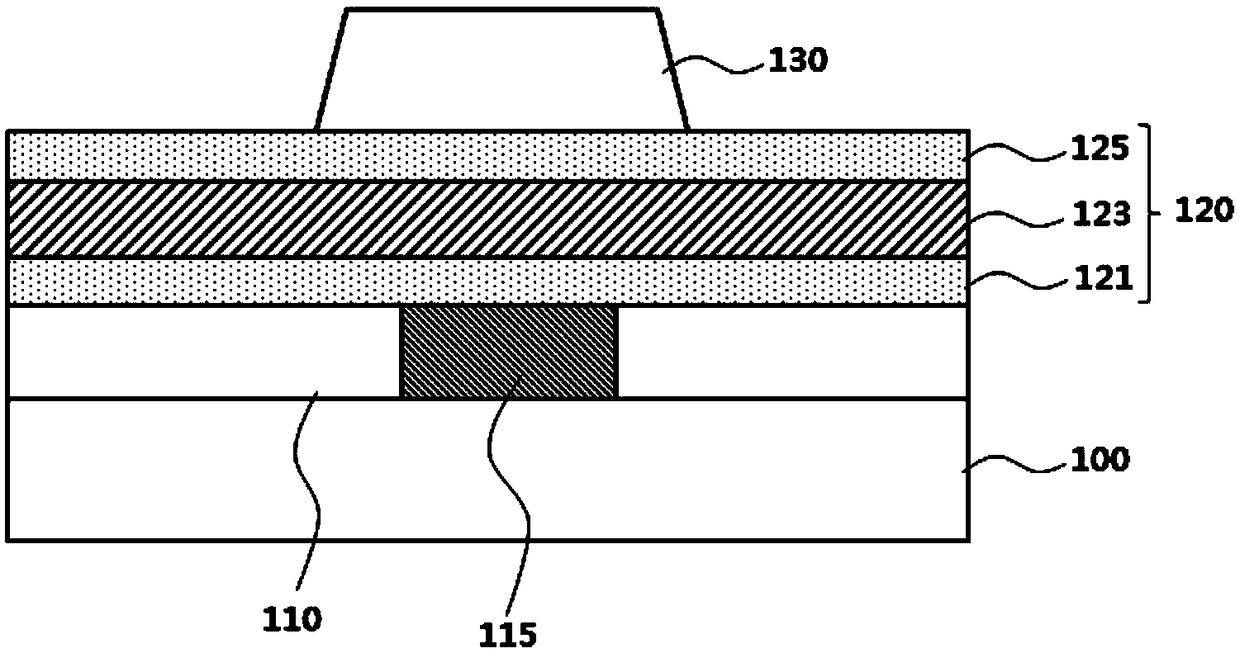

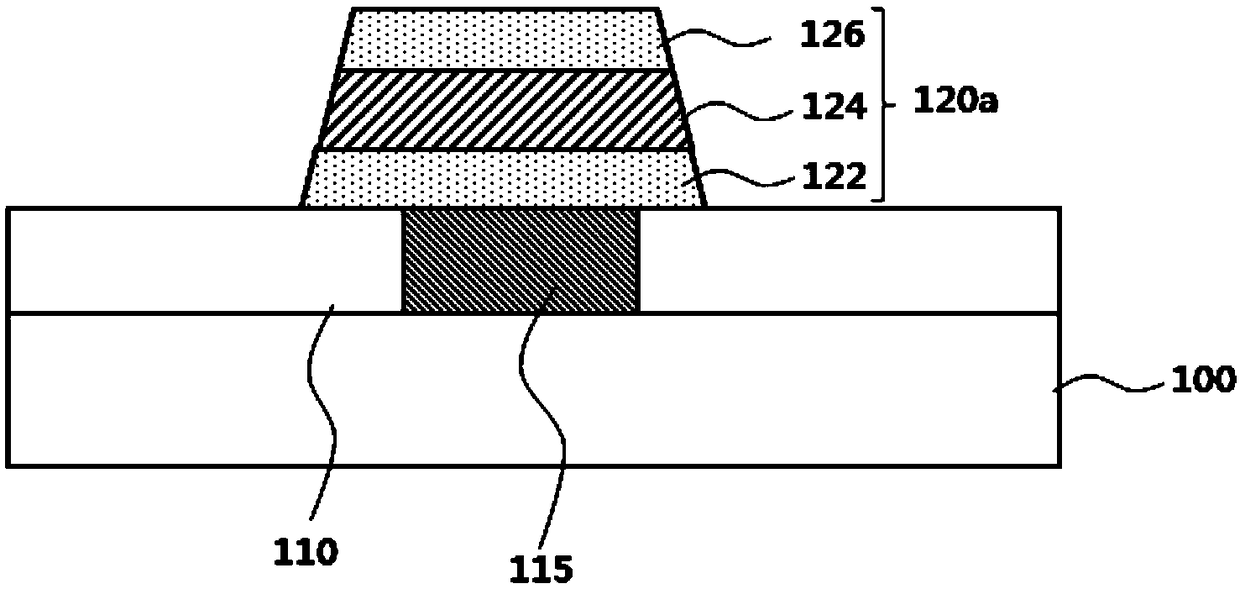

[0151] formed on a glass substrate The three-layer film was cut into a size of 10 cm×10 cm using a diamond knife to produce a sample.

[0152] An etching process is performed on the above-mentioned three-layer film through a photolithography process. Specifically, the etchant compositions of Examples and Comparative Examples were injected into a jet etching device (ETCHER, manufactured by K.C. Tech Co., Ltd.). After setting the temperature of the etching liquid composition to 40° C., when the temperature reached 40±0.1° C., the etching liquid composition was sprayed on the sample to implement an etching process for 85 seconds.

[0153] After the etching process, the above samples were cleaned with deionized water, dried with a hot air drying device, and the photoresist was removed using a photoresist stripper (PR stripper).

[0154] (1) Evaluation of silver resorption

[0155] About the etched sample, the whole-surface observation of the scanning electron microscope (SU-80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com