Silver-containing film etchant composition and conductive pattern forming method using same

A conductive pattern and etching solution technology, applied in the field of silver-containing film etching solution composition, can solve the problems of difference in etching rate, residue, low oxidation/reduction potential, etc., and achieve the effects of inhibiting re-precipitation and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

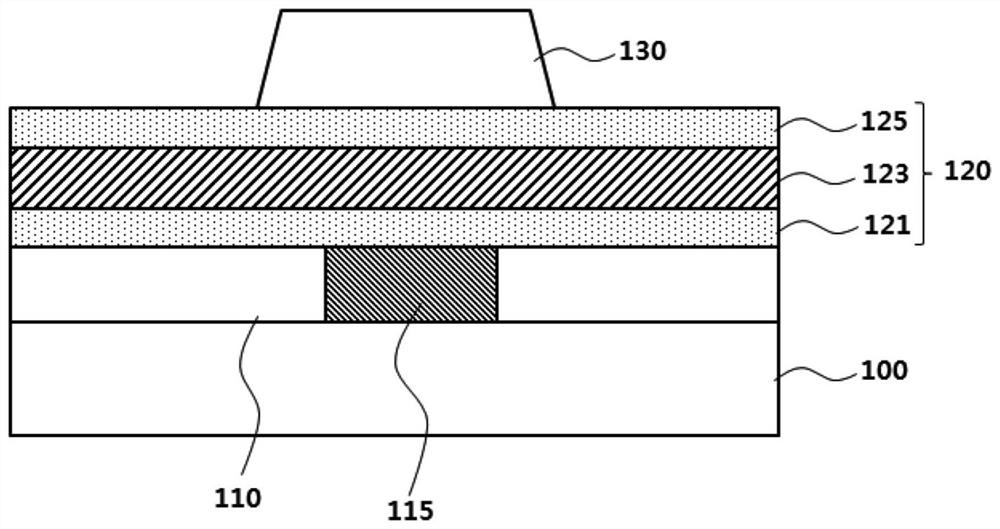

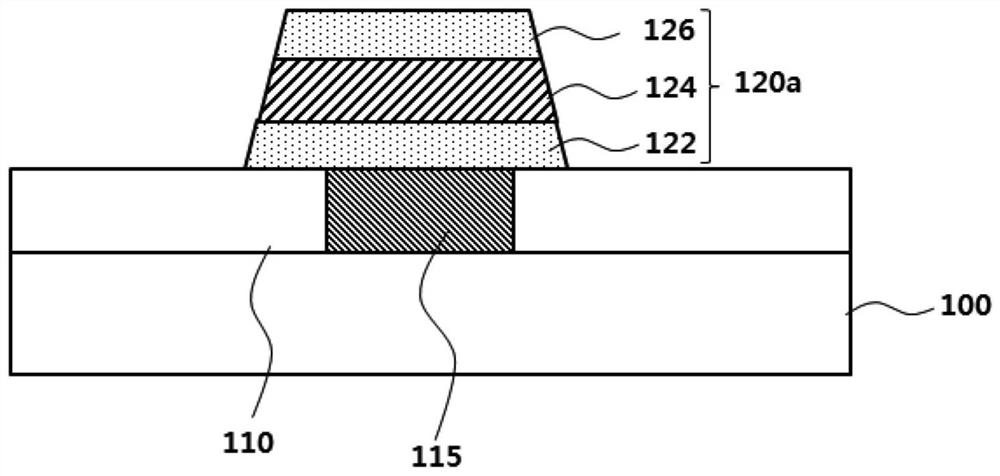

[0151] Form on the glass substrate Three-layer film, using a diamond knife and cut into a size of 10cmX10cm sample manufactured.

[0152] For the above-described three-layer film by photolithography etching step. Specifically, the etchant compositions of Examples and Comparative Examples of the etching apparatus in a jet injection (ETCHER, K.C.Tech Inc.) in. Ejecting the etching solution in the sample of composition embodiments 85 seconds when the temperature of the etching step, the etching solution after the composition was set to 40 ℃, the temperature reaches 40 ± 0.1 ℃.

[0153] After the etching step, the above samples washed with deionized water, drying by hot air drying apparatus, and using a photoresist stripping machine (PR stripper) the photoresist is removed.

[0154] (1) Evaluation of re-adsorbed silver

[0155] For sample was etched, was observed by a scanning electron microscope (SU-8010, manufactured by Hitachi Ltd.) in the entire surface, and then evaluate the ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

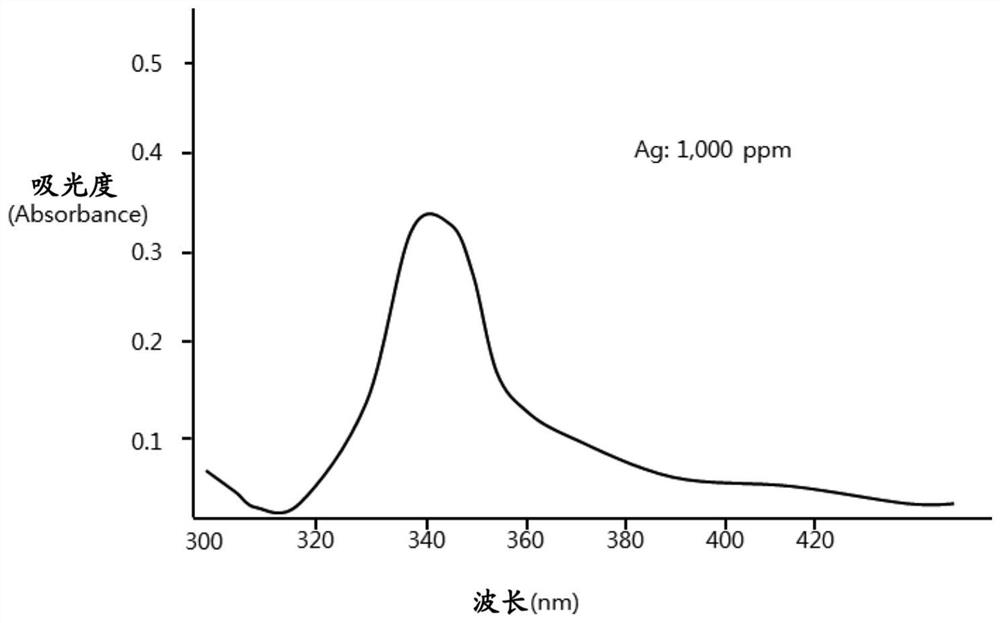

| absorption wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com