Stator lead-out wire connection structure of three-phase asynchronous generator

A generator stator and connection structure technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as difficult to ensure welding quality, uneven temperature distribution, plastic thermal deformation, etc., to reduce the risk of fatigue damage, The effect of reducing tensile stress and reducing force deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention will be further described below in conjunction with the accompanying drawings, but it is not used to limit the scope of the present invention.

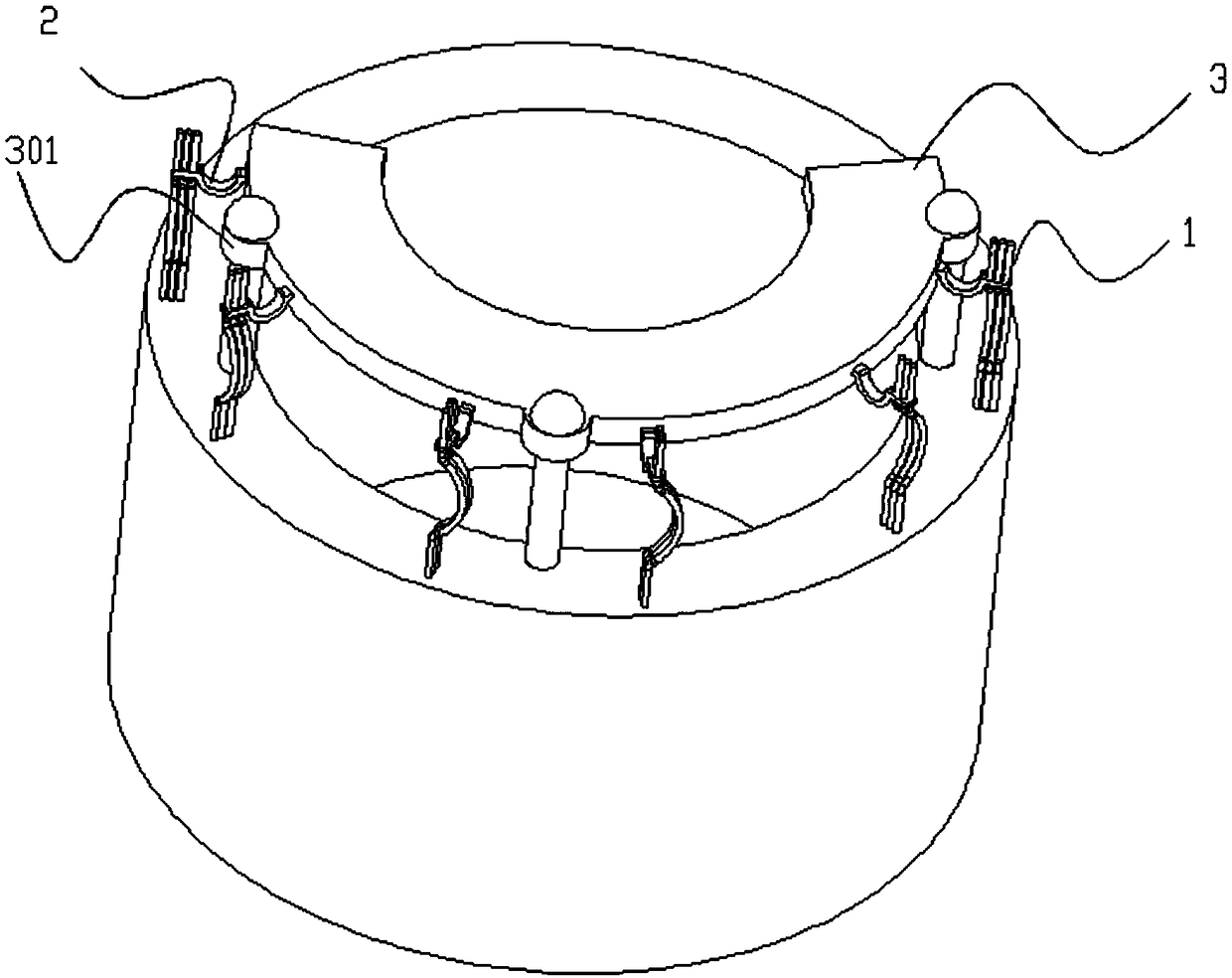

[0038] Such as Figure 1-Figure 2 As shown, the present invention provides a three-item asynchronous generator stator lead wire structure, including:

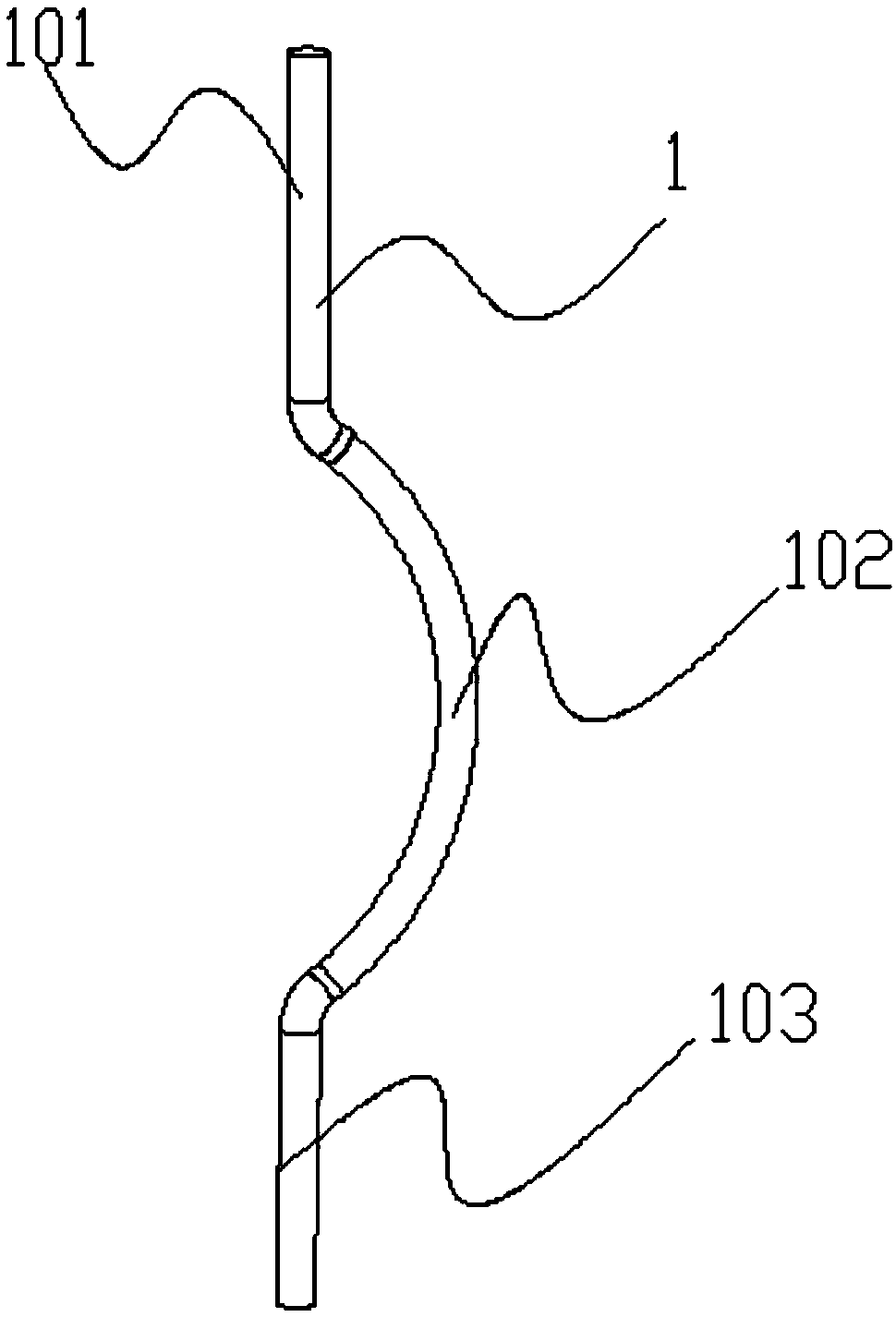

[0039] The single-turn buffered stator lead-out wire harness drawn from the stator winding, the single-turn buffered stator lead-out wire harness includes three stator lead-out wires 1, and the stator lead-out wire 1 includes a first vertical part 101, a curved part 102 and a second vertical part from top to bottom. Two vertical parts 103, the first vertical part 101 and the second vertical part 103 are arranged on the same horizontal plane, and the first vertical part 101 is connected to the special-shaped topology terminal 2 by resistance welding;

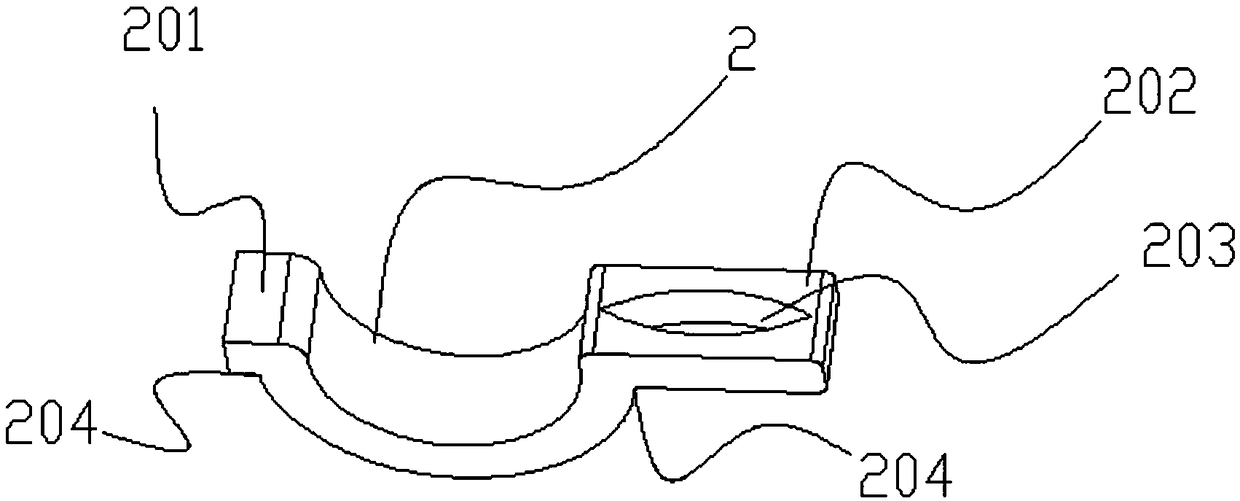

[0040] Such as Figure 3-Figure 4As shown, the special-shaped topology terminal 2 is set in a U shape, the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com