A double-fold composite beam structure and its construction method

A technology of composite beams and composite bridges, used in bridges, bridge parts, bridge construction, etc., can solve the problems of high construction time and cost, high construction costs, poor social benefits, etc., to reduce the risk of fatigue damage, and the bridge shape is light and beautiful , the effect of high comprehensive social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

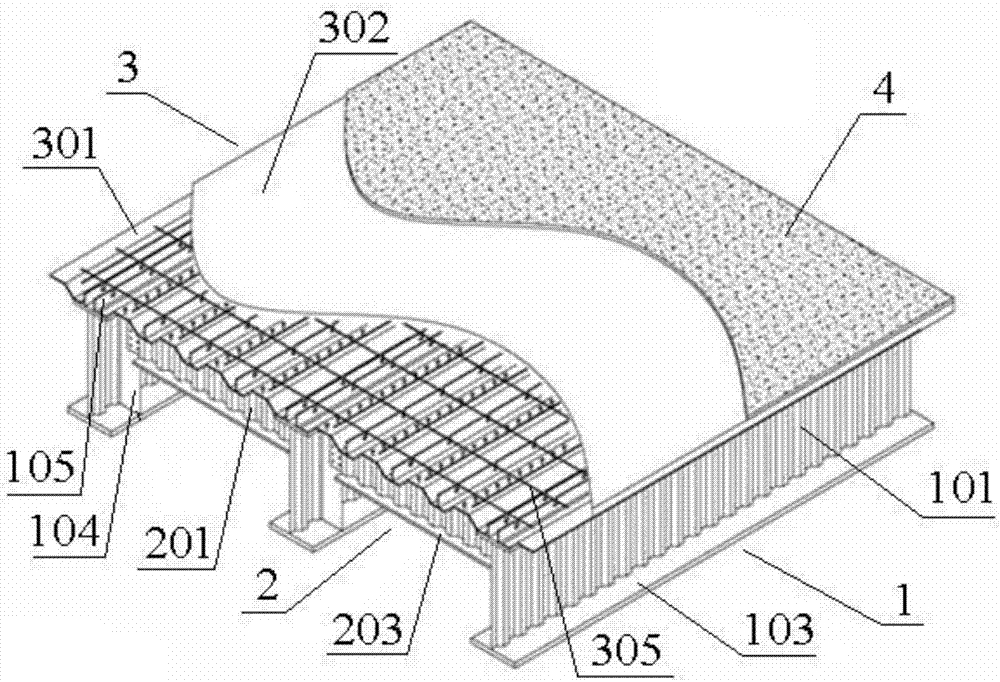

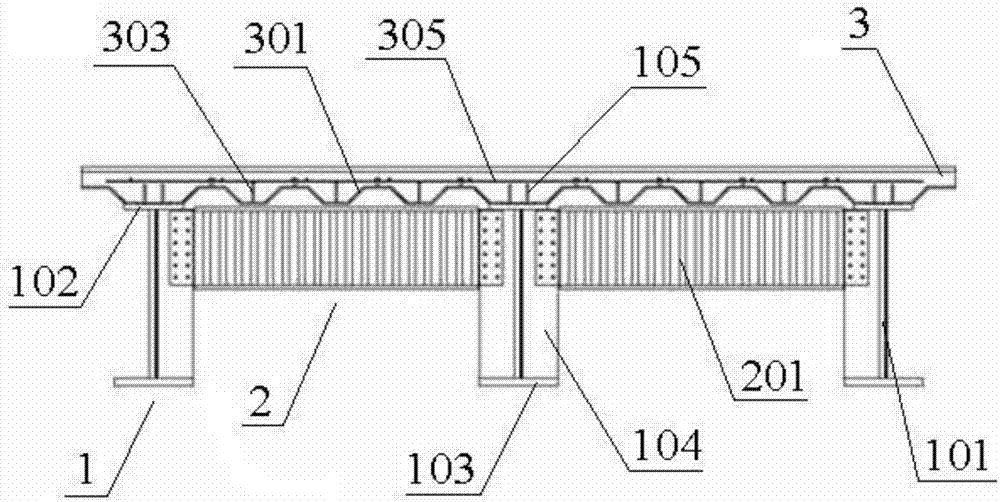

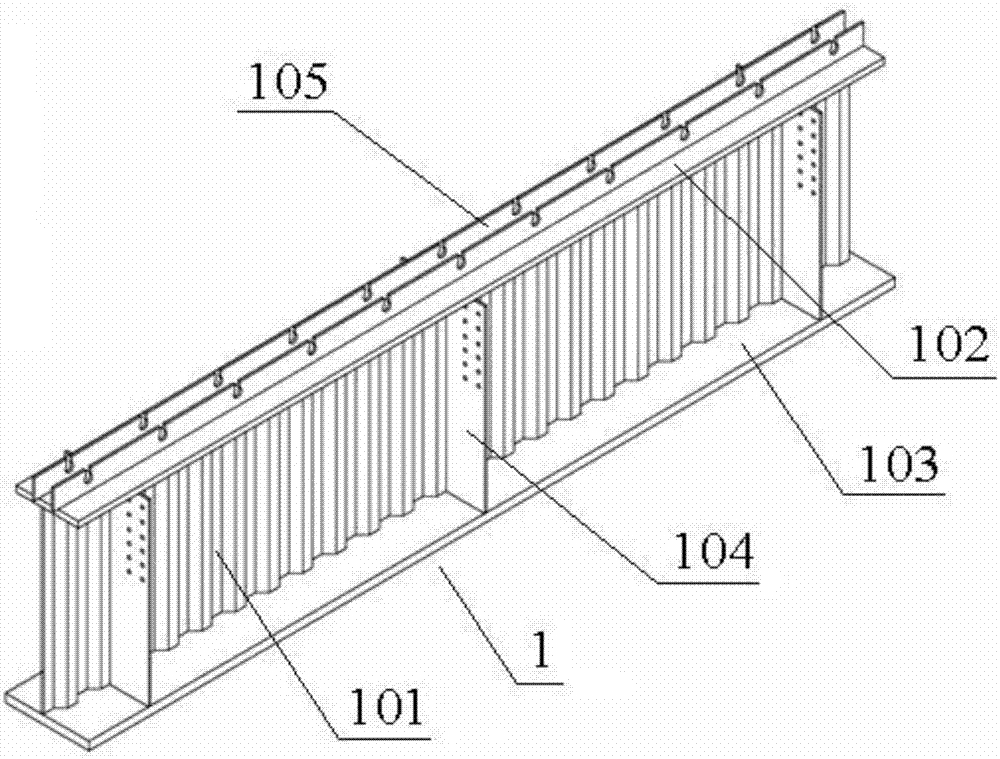

[0049] An embodiment of the double-fold composite beam structure and its construction method of the present invention, the double-fold composite beam structure is mainly suitable for large-scale application of small-span bridges in cities and highways of 20-50m and rapid urban transformation. The schematic diagram of the bifold composite beam structure is shown in Figure 1-Figure 5 shown by Figure 1-Figure 5 It can be seen that it mainly includes an I-shaped girder 1 , a steel transverse diaphragm 2 , a composite bridge deck 3 and a bridge deck pavement 4 . Among them, the I-shaped main girder 1 is connected to the steel transverse diaphragm 2, the composite bridge deck 3 is arranged above the I-shaped main beam 1 and the steel transverse diaphragm 2, and the bridge deck pavement 4 is laid on the composite bridge deck 3 . The I-shaped main girder 1 includes a main girder folded steel web 101, a main girder upper flange steel plate 102 welded above the main girder folded st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com