Charging pile structure

A charging pile and charging plug technology, used in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of short circuit risk safety, access to charging plugs, hidden dangers, etc., to avoid safety accidents, achieve rain protection, and ensure smooth The effect of charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

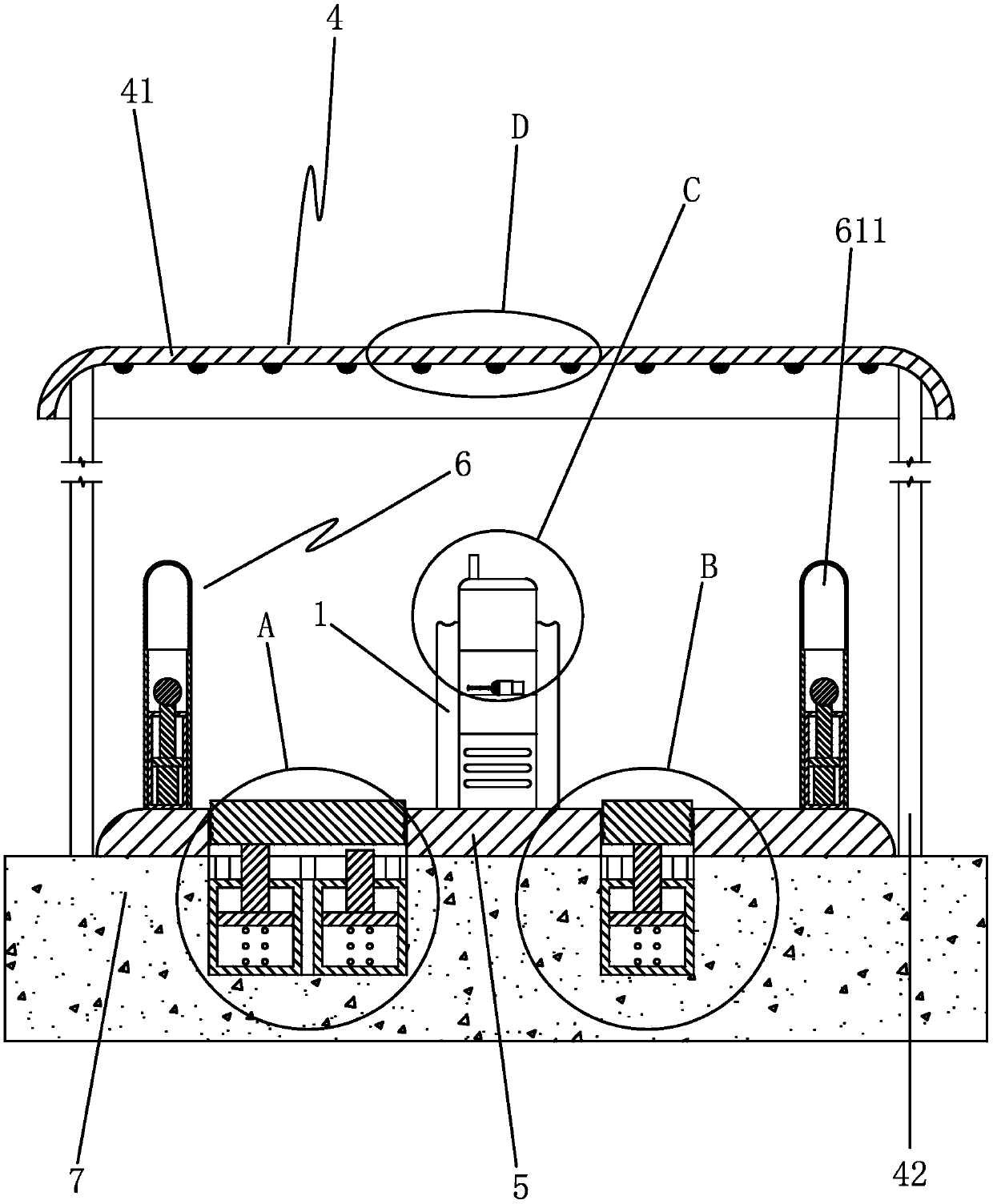

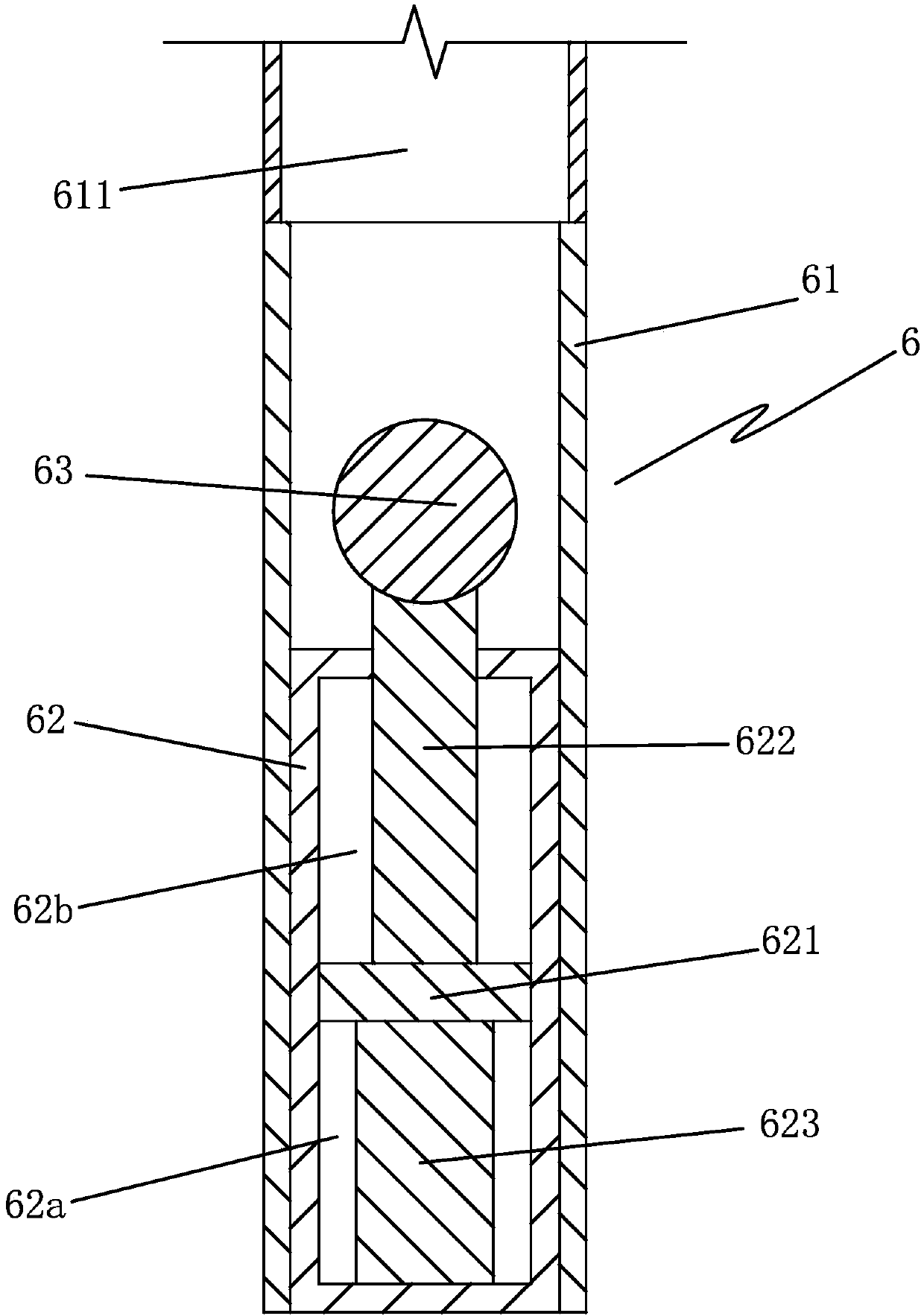

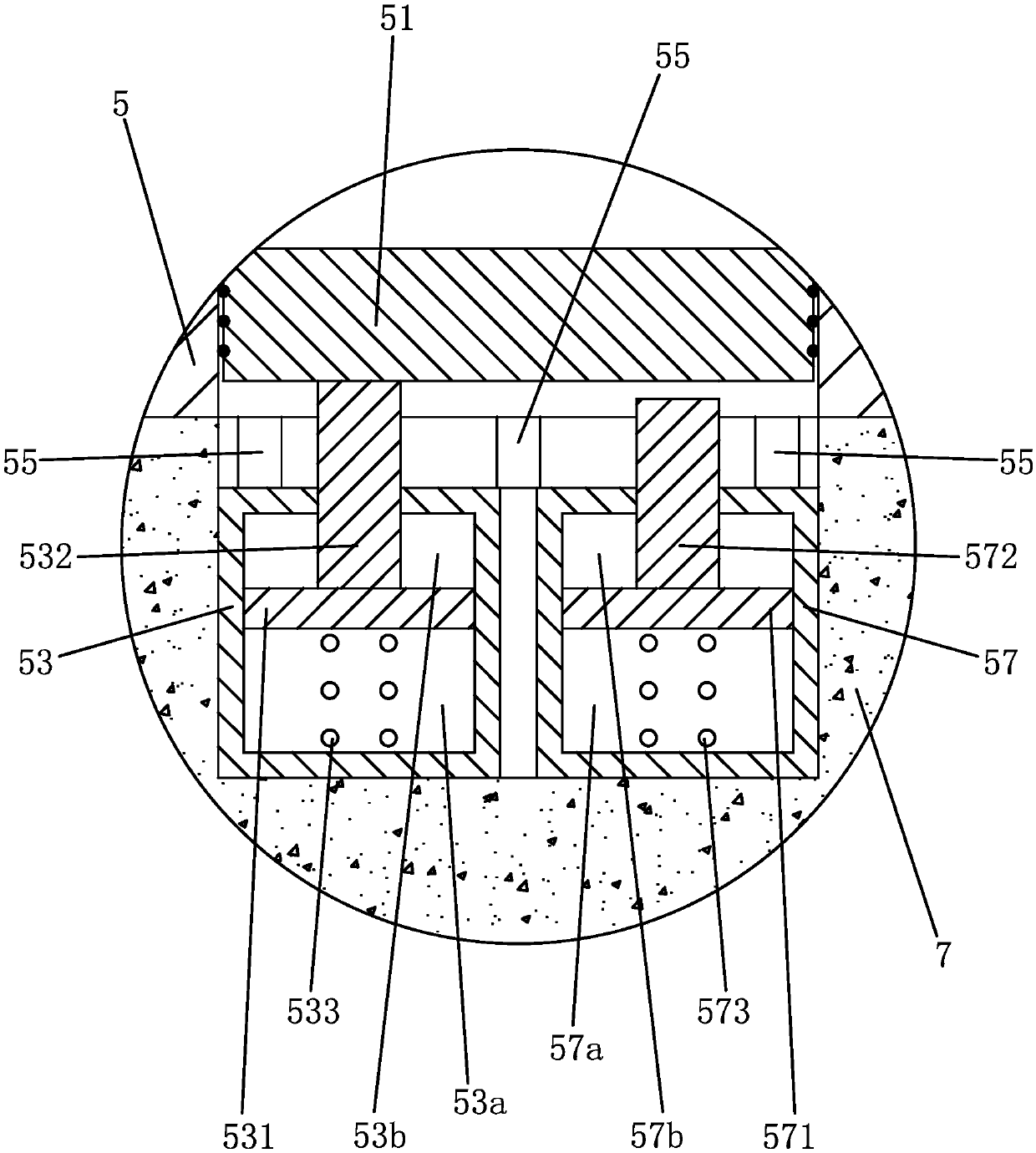

[0044] Such as Figure 1 to Figure 12 as shown,

[0045] A charging pile structure, including a charging pile body 1 and a charging line, the charging pile body is provided with a housing space 1a, and the charging line includes an inner cable section connected to a power supply network, and an outer cable section in the accommodation space 2 and the charging plug seat 3 for docking with the charging socket of the electric vehicle, the inner cable section, the outer cable section and the charging plug seat are electrically connected in turn, the charging plug seat includes a plurality of metal pins 31, and the charging plug seat is located in the accommodation space middle;

[0046] It also includes canopy 4, platform plate 5, two indicating mechanisms 6, the first ground trough on the ground 7 and the second ground trough on the ground, the platform plate is fixed to the ground, and the charging pile body is fixed on the ground , the canopy includes a ceiling 41 and several...

Embodiment 2

[0063] Embodiment 2: based on embodiment 1, such as Figure 13 to Figure 17 as shown,

[0064] The base is provided with a dust-proof plate 37 that slides and seals with the base. The axis of the inner cylinder is horizontal, and the sliding direction of the dust-proof plate is vertical. There is a moving magnet block 372, a fixed magnet block 341 which can be magnetically adsorbed to the moving magnet block is arranged on the middle cylinder, two plate through holes 37a are arranged on the dustproof plate, a part of pin holes correspond to a plate through hole, and the remaining pins The hole corresponds to another plate through hole, and all the plate through holes are sealed by the dust plate;

[0065] When the bottom surface of the first wheel pressure plate contacts the first ground limit block and the bottom surface of the second wheel pressure plate contacts the second ground limit block, the moving magnetic block is separated from the fixed magnetic block, the dust-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com