Film tearing and turnover attaching device

A mounting device and mounting technology, which are applied in the field of tear-off and flip-mounting devices, can solve the problems of affecting the quality of bonding, high cost of feeding, limited number of diaphragms, etc. Multi-piece inspection process and structure, the effect of reducing the cost of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

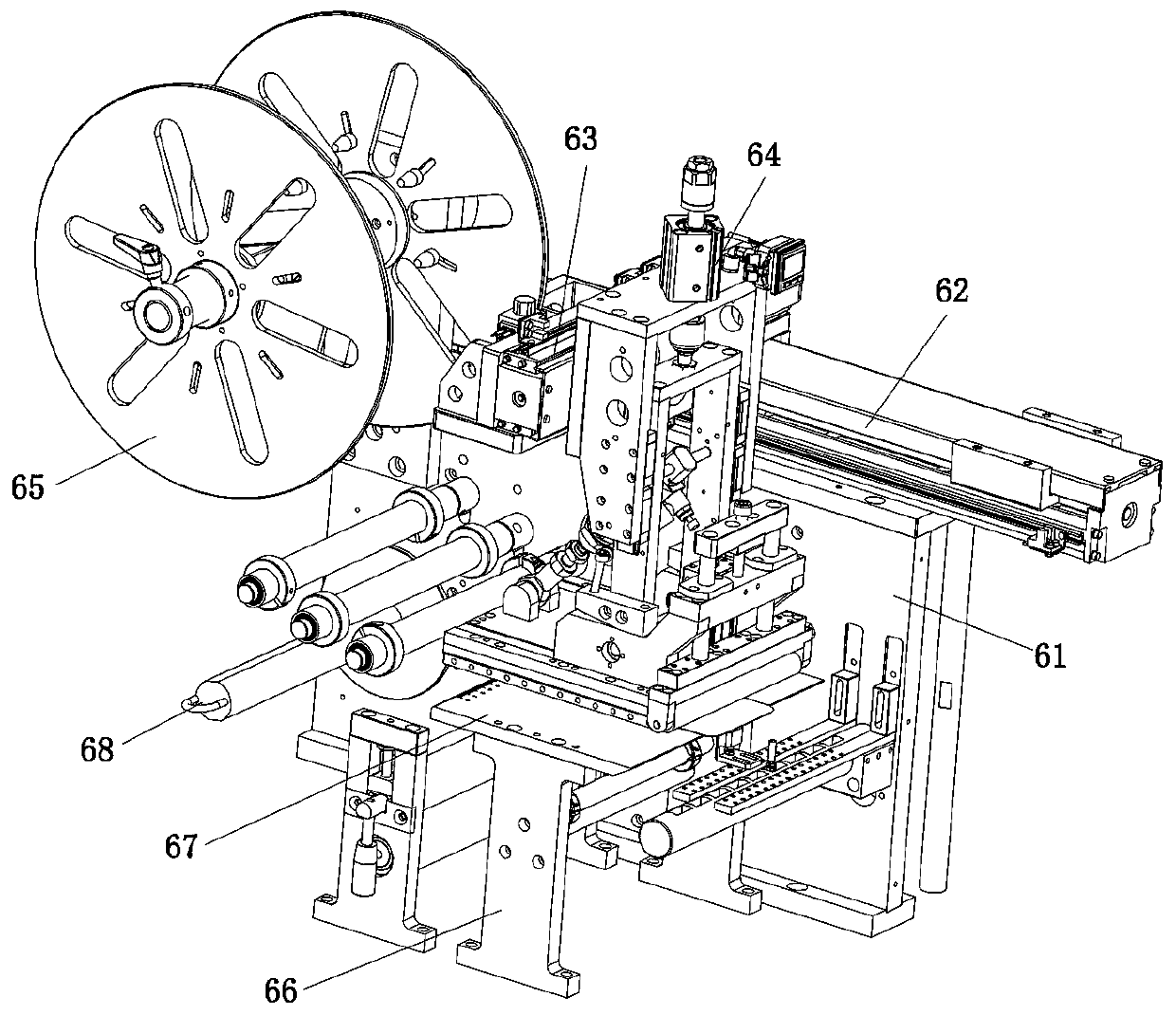

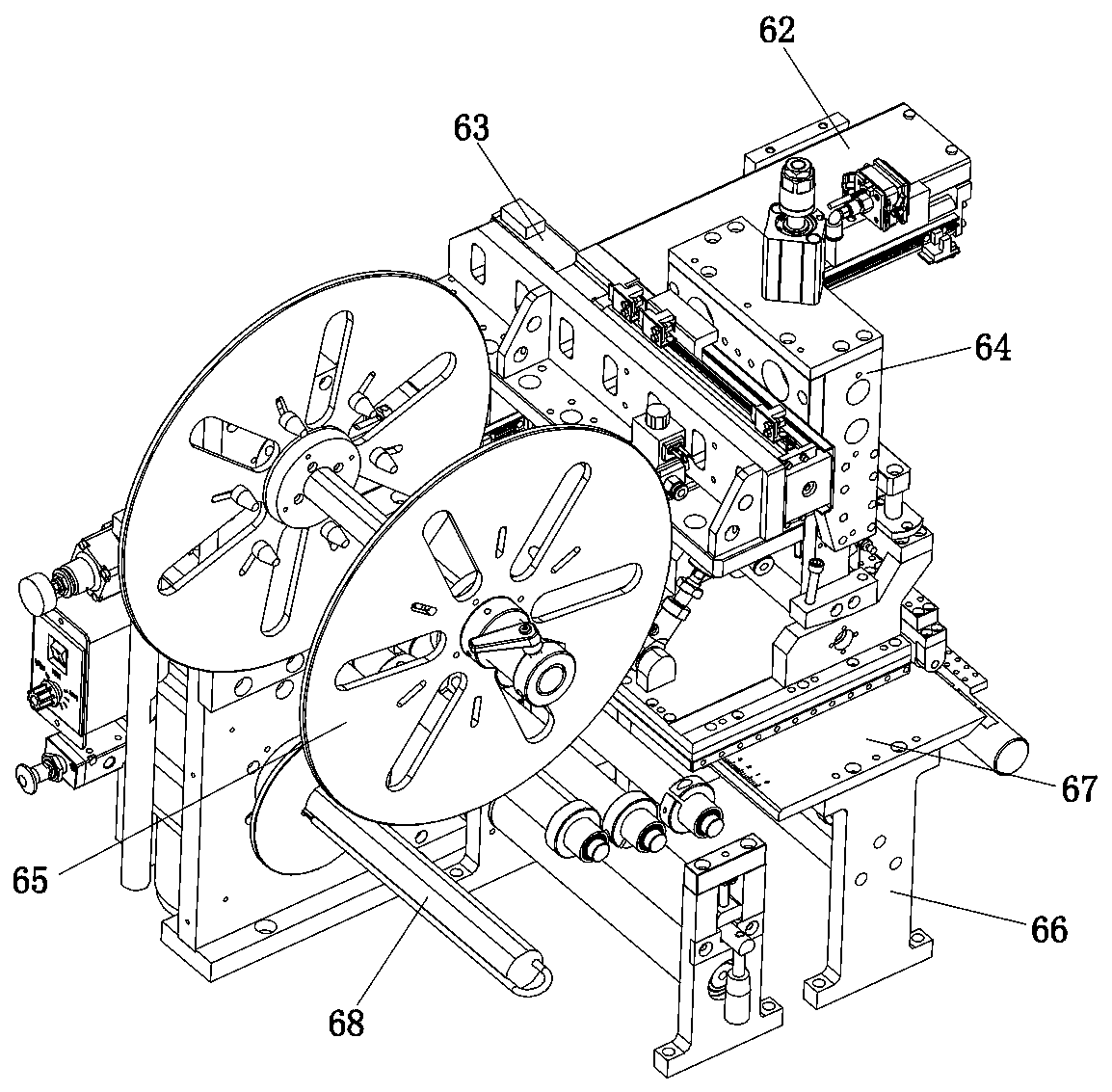

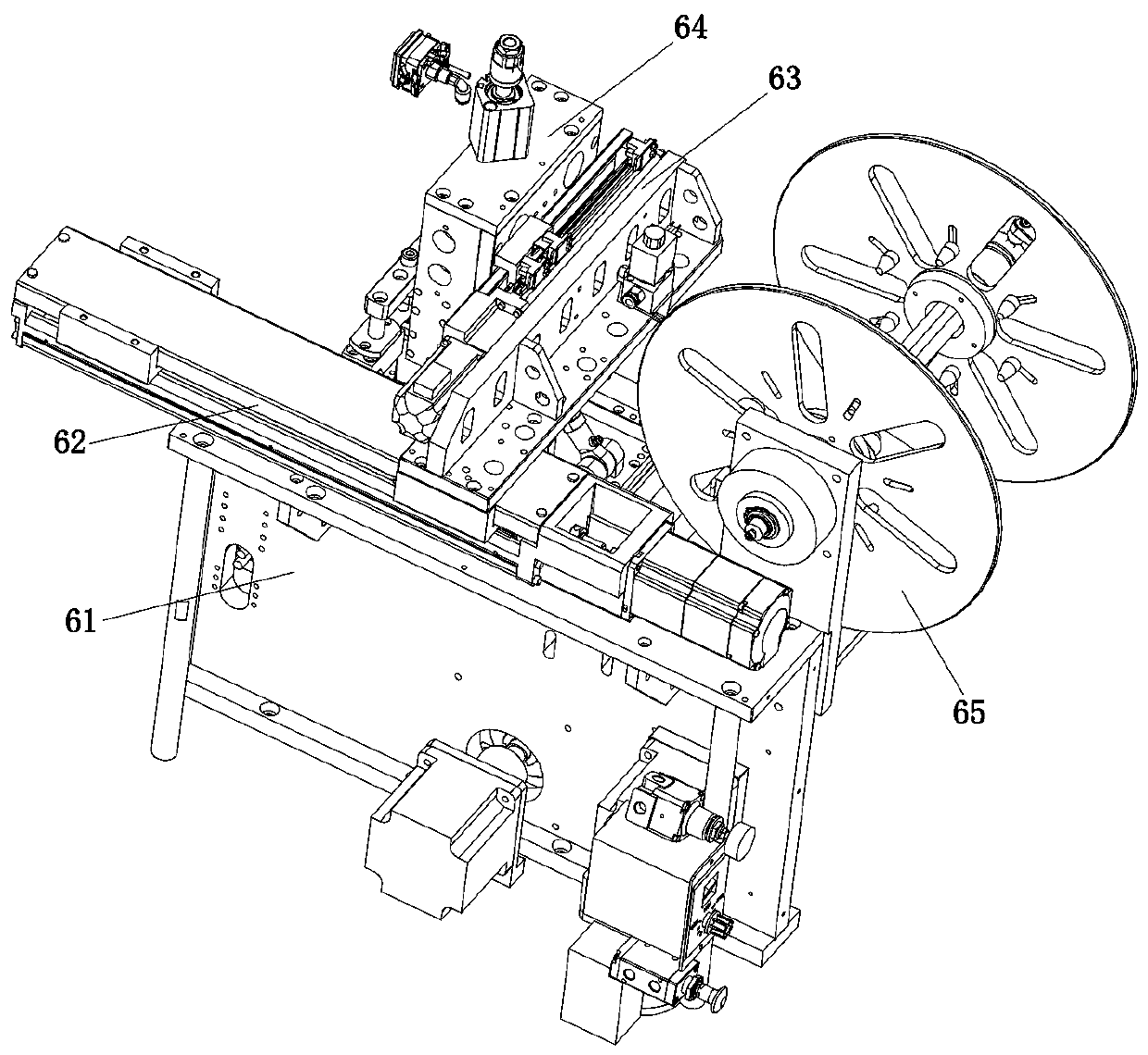

[0023] Such as Figure 1 to Figure 7 As shown, the technical solution adopted by the present invention is as follows: a film tearing and flipping and mounting device, which is installed in the film laminating machine, is used to tear off the film to be bonded and bond it to the glass panel , including a film-out component, a mounting support plate 61, a first mounting linear module 62, a second mounting linear module 63 and a mounting head 64, wherein the above-mentioned mounting support plate 61 is vertically arranged on the film sticking On the frame of the machine, the film-exiting part is arranged on one side of the mounting support plate 61, and the film-exiting part is wound with a material tape with a plurality of sheets to be pasted. , the film to be bonded is peeled off from the tape; the above-mentioned first placement linear module 62 is arranged on the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com