Pallet protection corner automatic putting machine

A technology of corner protectors and pallets, which is applied to the parts of strapping machines, bundled objects, packaging/bundled objects, etc., can solve the problems of not being able to meet the placement of corner protectors, consume a lot of manpower, and take time to operate, so as to improve flexibility and Applicability, smooth operation, precise position effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

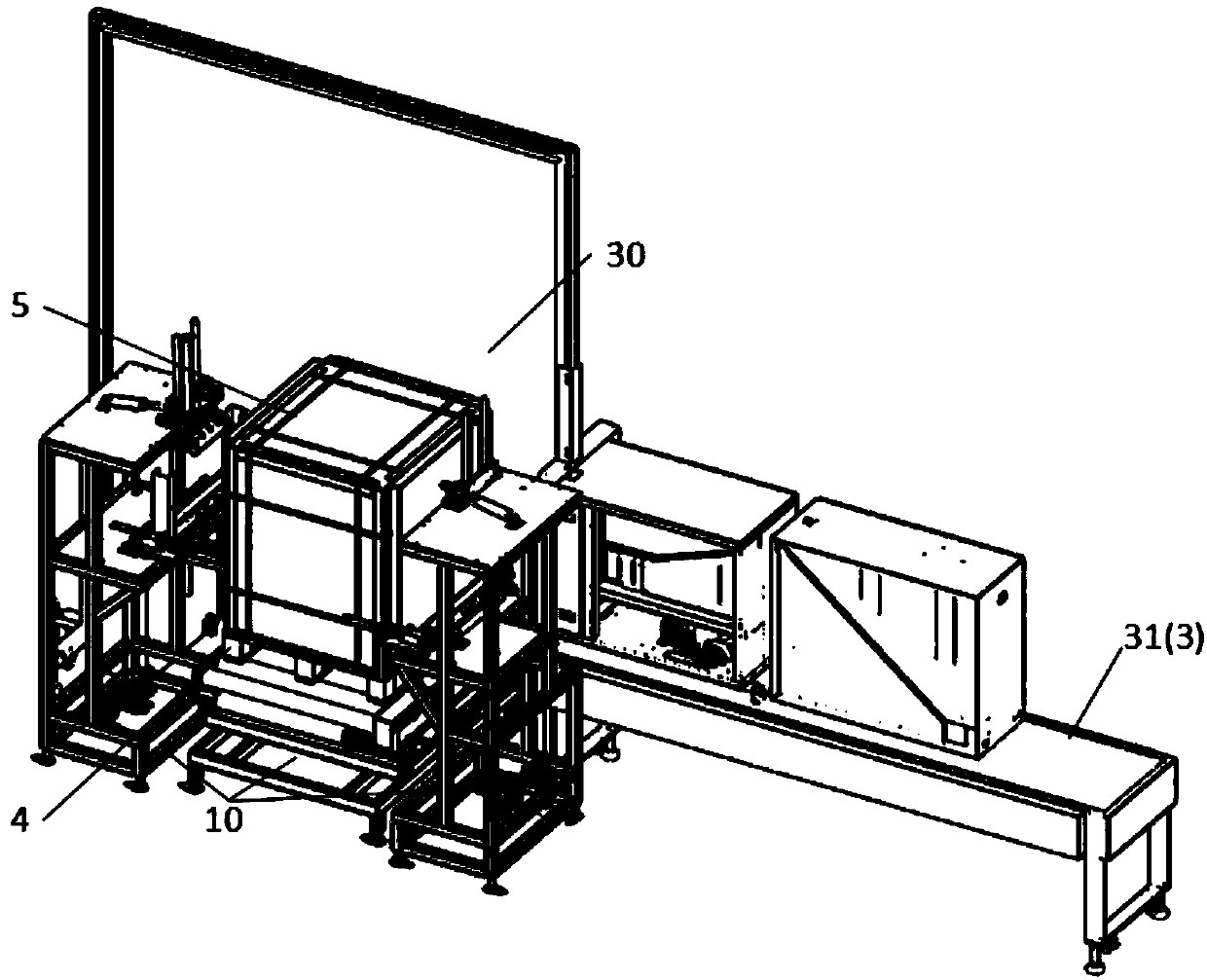

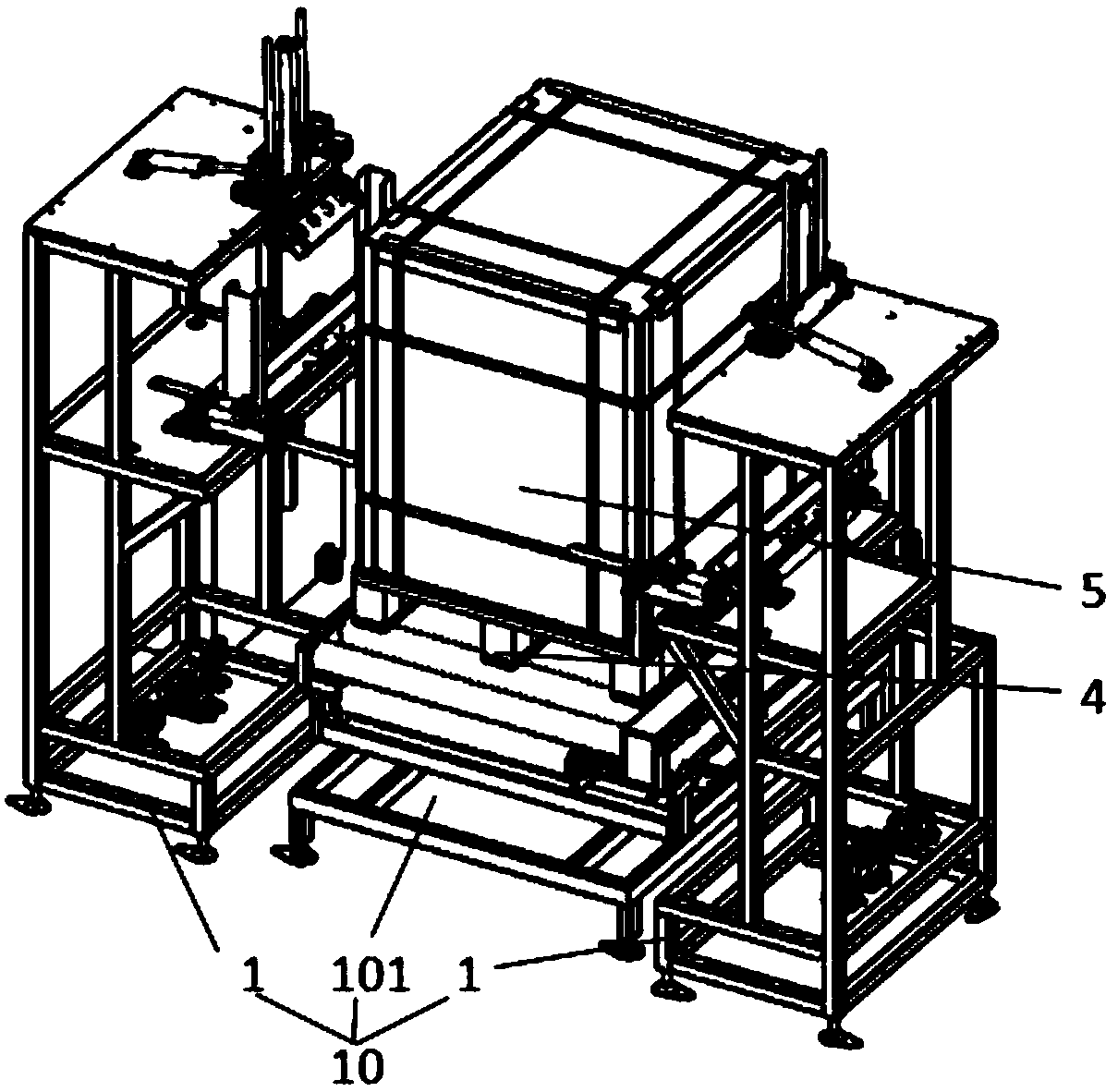

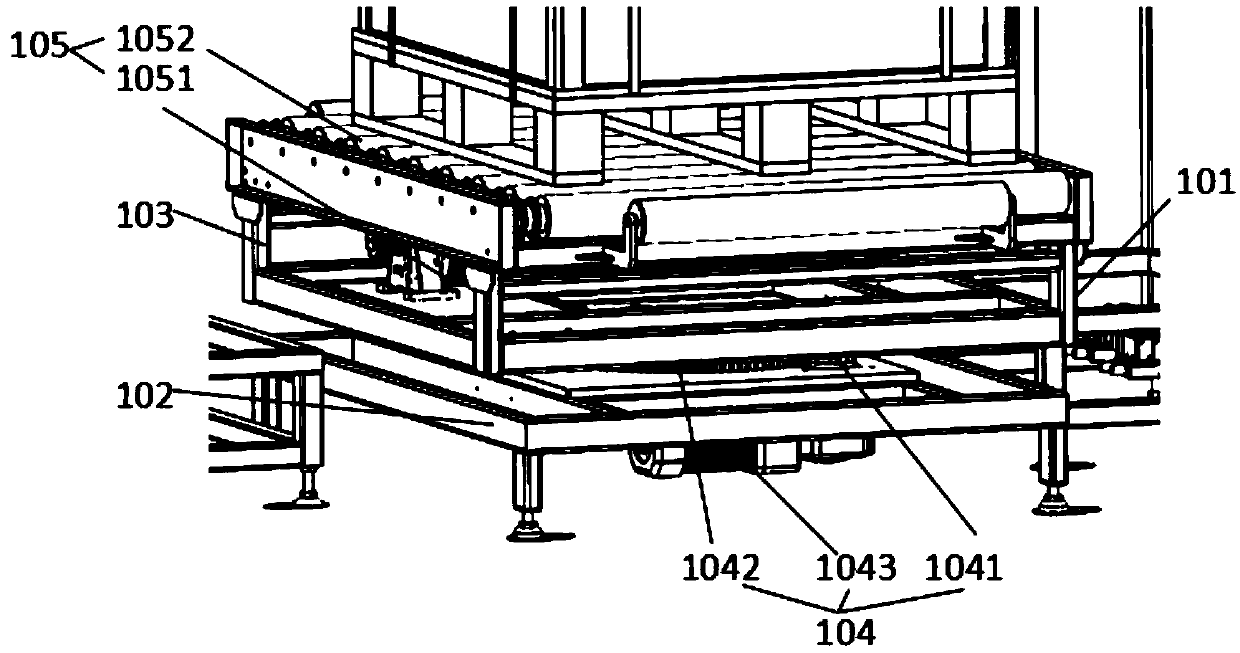

[0024] Such as Figure 1-14 , an automatic pallet corner protection machine, used for placing corner protection 6 with four edges on the top and four edges on the sides of a cuboid-shaped packing box 5, and used in conjunction with a threading packing machine 3, which includes a longitudinal threading packing machine 31. A cross-line packing machine 32 has a packing area 30 inside the threading packing machine, and the bottom four edges of the packing box 5 are placed on the bottom pallet 4;

[0025] The pallet corner automatic placing machine includes a top corner protection set machine 10 for top four-edge corner protection placement, a side corner protection set machine 20 for side four-edge corner protection placement, and a top corner protection set set machine 10 and The side corner protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com