Inverted U-shaped prestressed steel strand anti-slip device and method

A technology for prestressed steel strands and steel strands, which is used in construction, building construction, and construction material processing to achieve the effect of improving construction safety quality, highlighting substantive features, and making significant progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

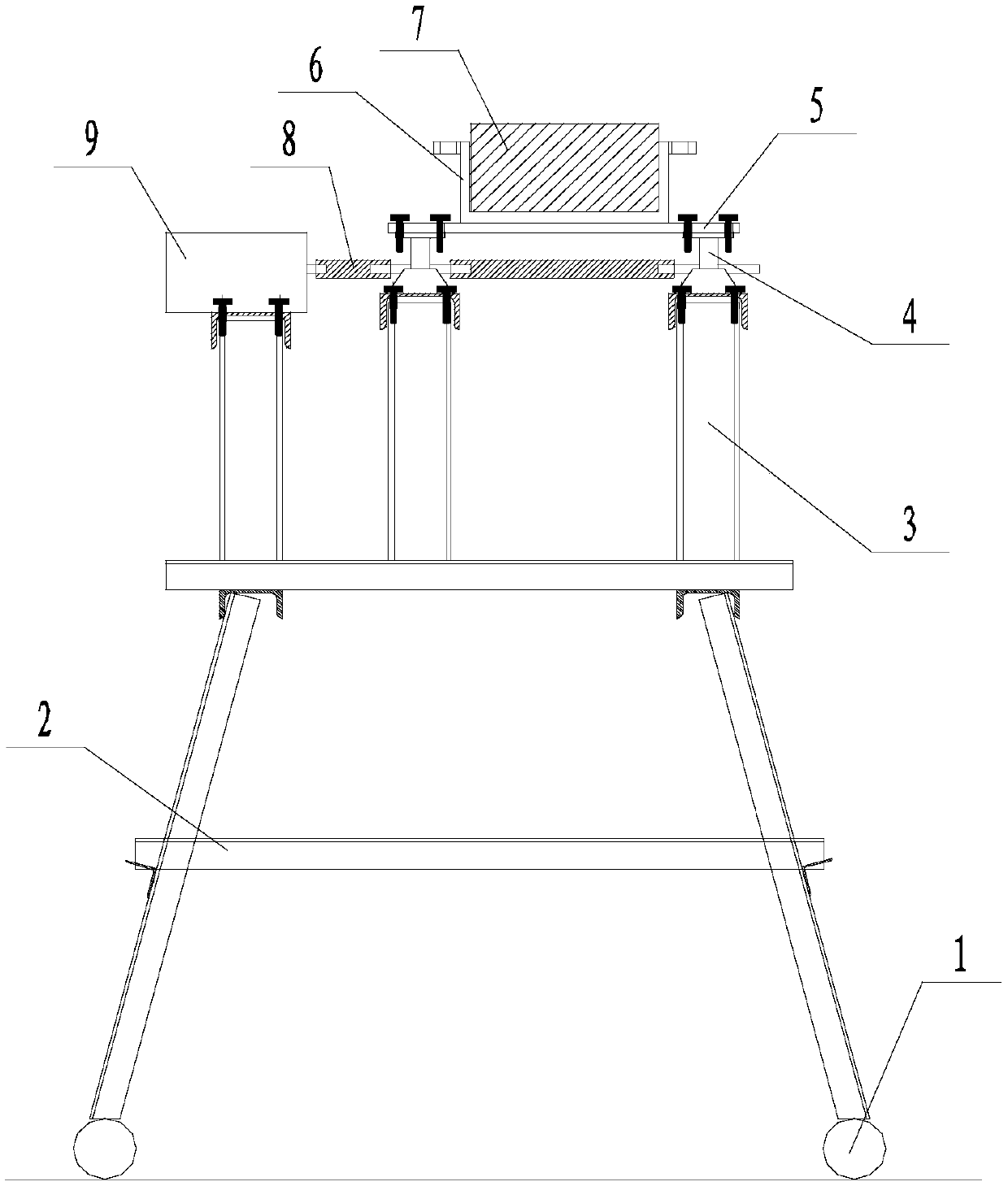

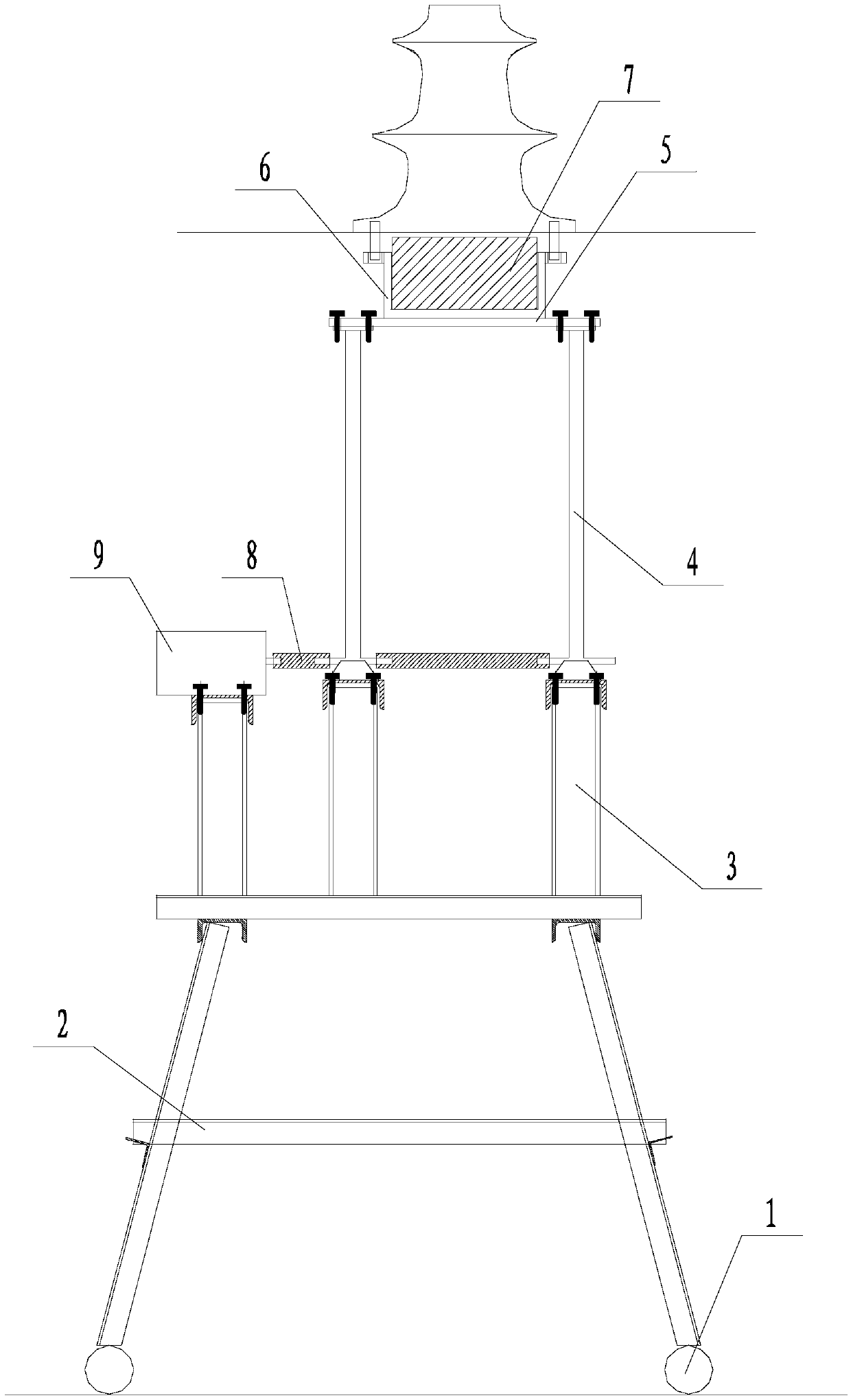

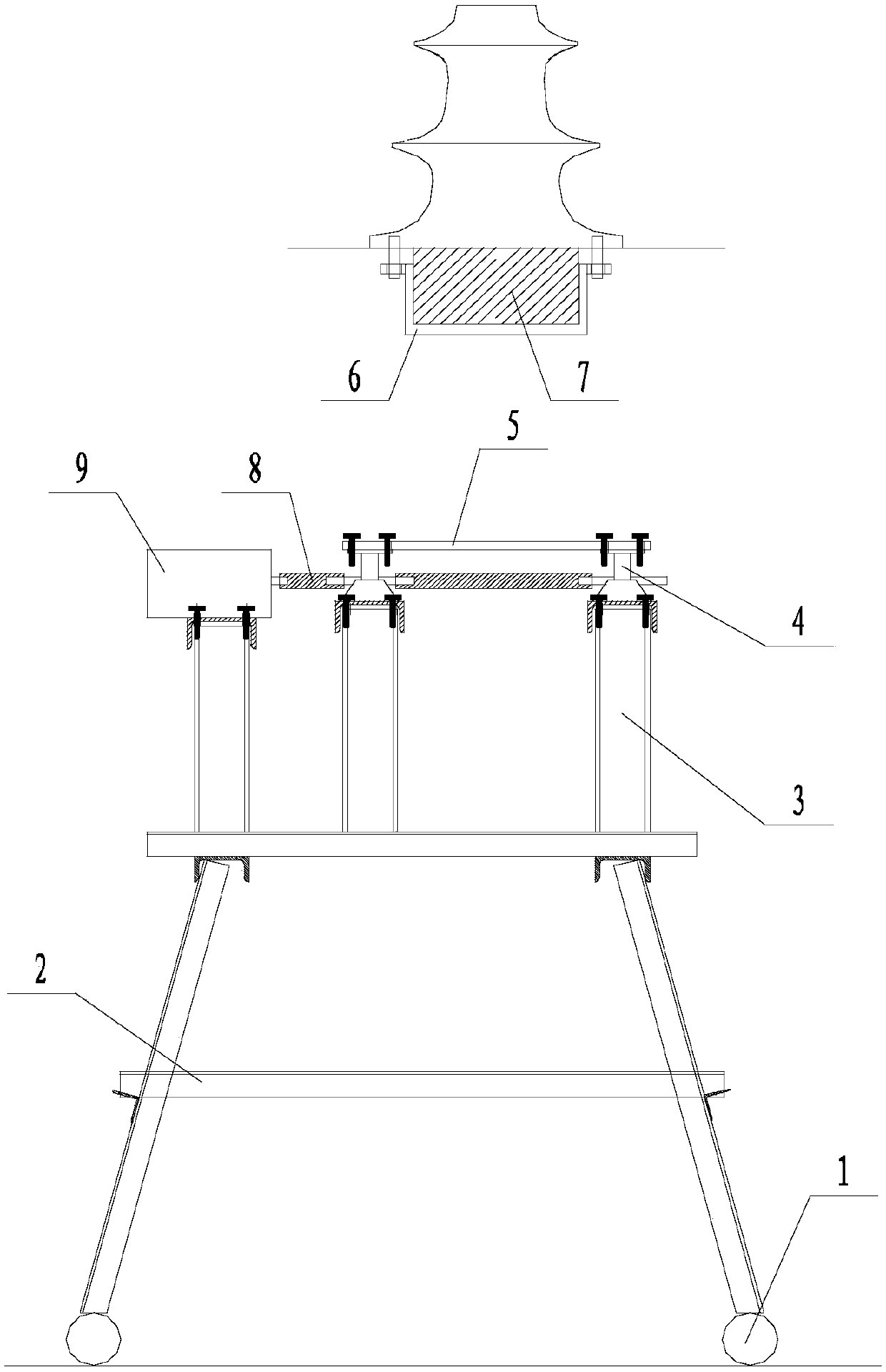

[0038] Such as Figure 1 to Figure 7 The shown anti-slip device of an inverted U-shaped prestressed steel strand includes a steel strand anchor plate 7 and a base 3 on which a lifting mechanism 4 is arranged, and the lifting mechanism 4 is used to drive the supporting plate 5 to lift , the anchor plate cover 6 is placed on the supporting plate 5, the upper end of the anchor plate cover 6 is open, the steel strand anchor plate 7 is placed in the anchor plate cover 6, and the bottom surface of the anchor plate cover 6 is provided with some perforations, and some perforations are connected to the anchor plate cover 6. The through holes on the steel strand anchor plate 7 are facing each other one by one.

Embodiment 2

[0040] Such as Figure 1 to Figure 7 The shown anti-slip device of an inverted U-shaped prestressed steel strand, on the basis of Embodiment 1, also includes a clip that matches the anchor plate 7 of the steel strand, and the clip is set from the anchor plate The bottom of 6 is inserted in the perforation and clamps the steel strand; it also includes an anti-dropping device for preventing the clip from falling. The anti-falling device is a locking rod 11, which is detachably connected to the bottom of the anchor plate sleeve 6, and the locking rod 11 is used to hold the clip from below. The base 3 is fixed on the platform 2, and the bottom of the platform 2 is provided with a universal wheel 1 with a brake. The lifting mechanism 4 is a screw lift, and the screw lift is driven by a motor 9 through a transmission rod 8 . The supporting plate 5 is provided with a flange mounting hole 14 for connecting with the screw lifter, and a wire hole 16 facing the steel strand anchor plat...

Embodiment 3

[0042] This embodiment takes the containment construction of a certain nuclear power plant as an example. The inverted U-shaped prestressed steel strands of the nuclear power plant containment are each about 195m long, composed of 55 steel strands, and weigh about 13 tons. The height is 82m, and the bell mouths at both ends of the conduit are distributed on the roof of the corridor. When threading, 55 steel strands need to be bundled in the corridor, and then pulled into the tunnel as a whole, which makes the construction difficult and the safety risk is extremely high. Among them, the anti-slip method of the inverted U-shaped prestressed steel strand is:

[0043] (a) Place the steel strand anchor plate 7 in the anchor plate sleeve 6, make the fixing hole 15 face the fixing bolt 13, screw the fixing bolt 13 into the anchor plate sleeve 6 and enter the fixing hole 15 to lock the steel strand anchor plate 7;

[0044] (b) Place the anchor plate sleeve 6 on the supporting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com