Fan and extractor hood applying same

A fan and oil filter technology, applied in the field of range hoods, can solve problems affecting filter performance, etc., and achieve the effect of keeping clean and good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

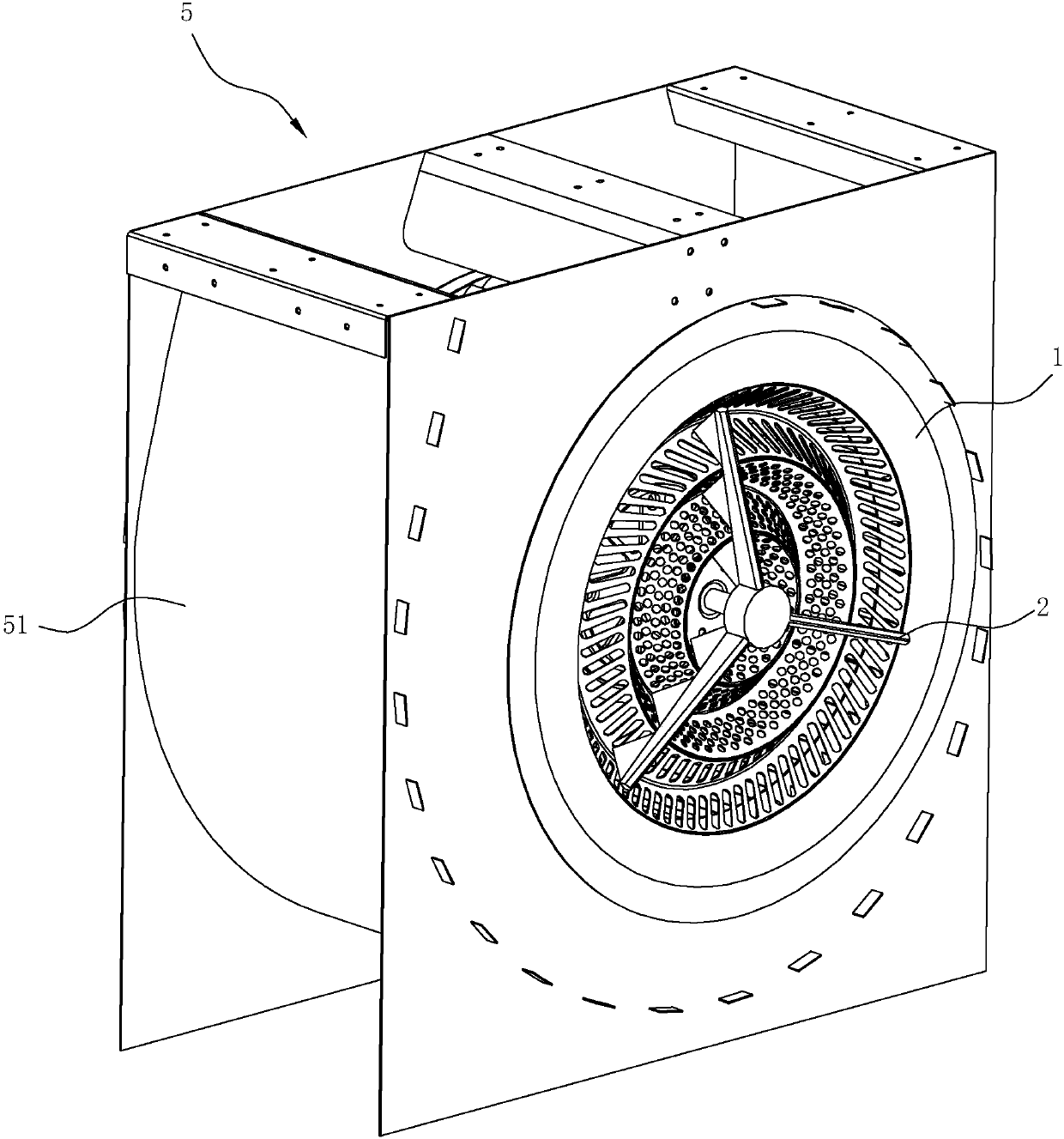

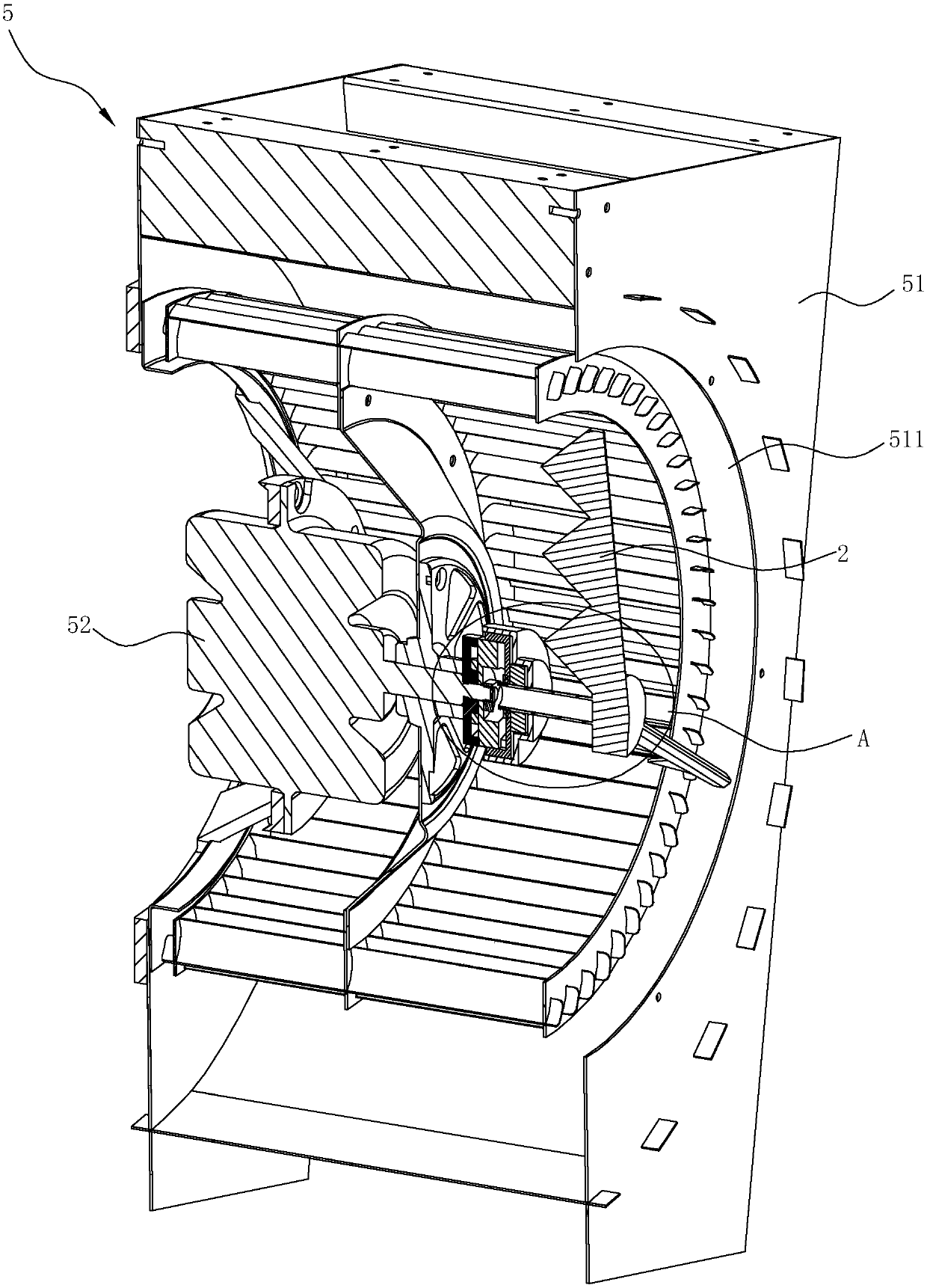

[0025] like Figure 1~6 As shown, the blower fan 5 of this embodiment includes a casing 51, a motor 52 and an oil filter 1, the motor 52 is arranged in the casing 51, the casing 51 has an air inlet 511, and the oil filter 1 is fixed on the air inlet 511. The oil screen 1 has an oil filtering hole 10 .

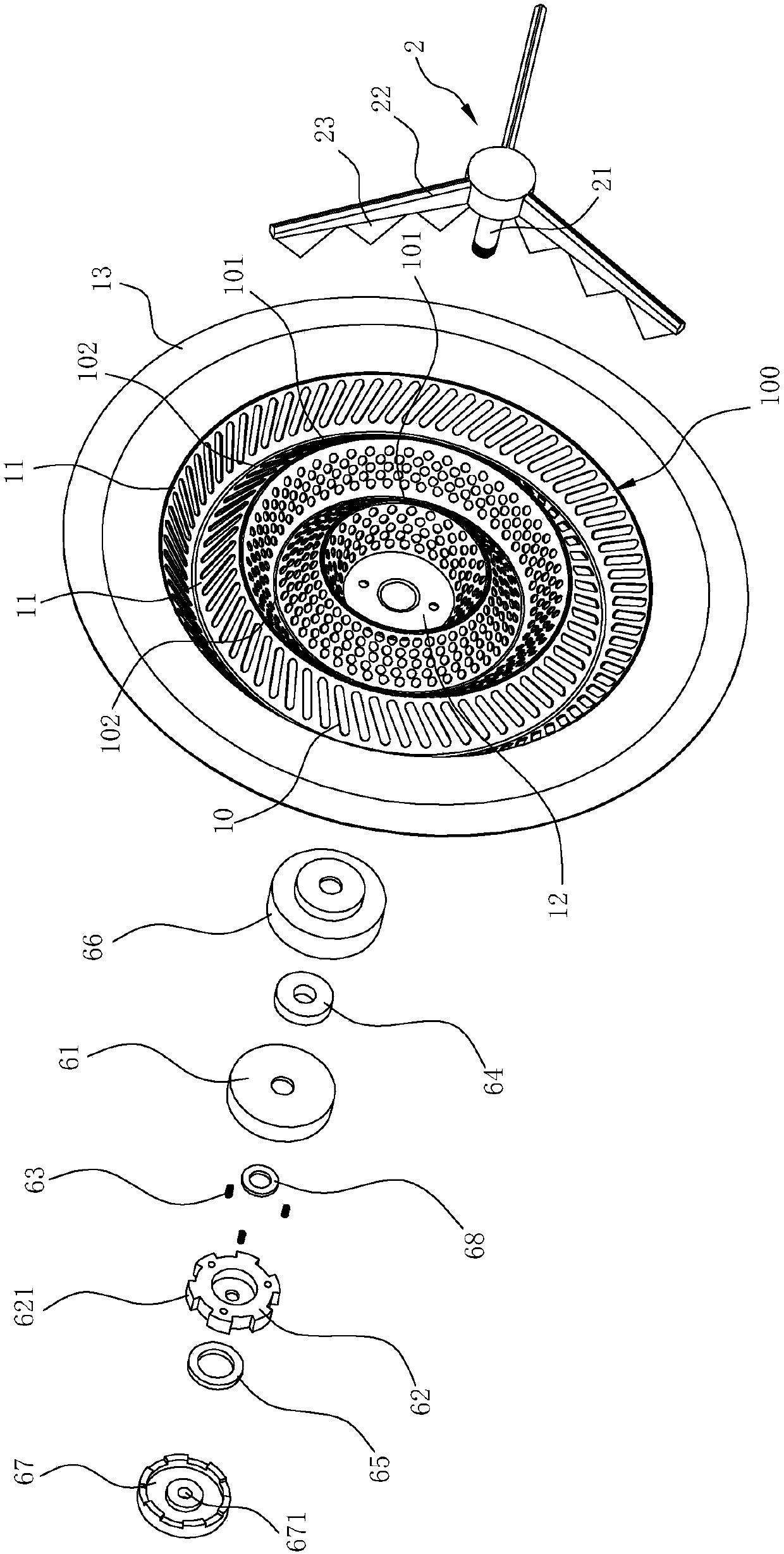

[0026] The oil filter screen 1 of this embodiment includes a plurality of annular ventilation surfaces 11, and the oil filter screen 1 is sequentially connected by at least three ventilation surfaces 11 in the radial direction to form an oil filter main body 100, and the adjacent ventilation surfaces The inclination direction of 11 is different and presents the ups and downs wavy structure in the radial direction, and each ventilating surface 11 is all opened with oil filter hole 11. Each annular ventilation surface 11 is a concentric ring, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com