Integrated stove capable of exhausting and sucking smoke with high efficiency

An integrated stove and oil fume exhaust technology, applied in the field of integrated stoves, can solve the problems affecting air curtain sealing, increased cost, weakened wind power, etc., so as to ensure the effect of sucking oil fume, facilitate maintenance of fans, and prevent outward diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with accompanying drawing, the present invention will be further described:

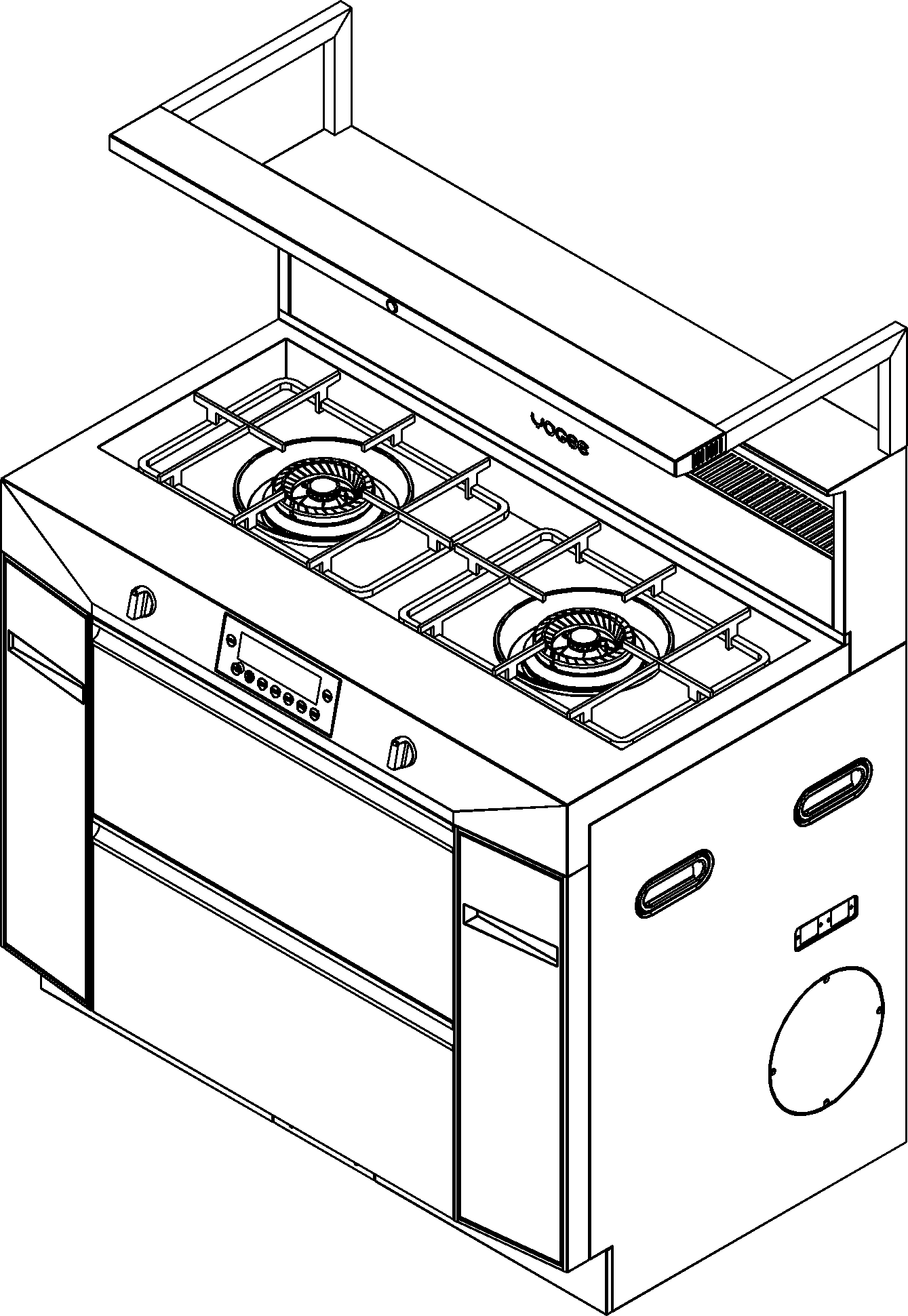

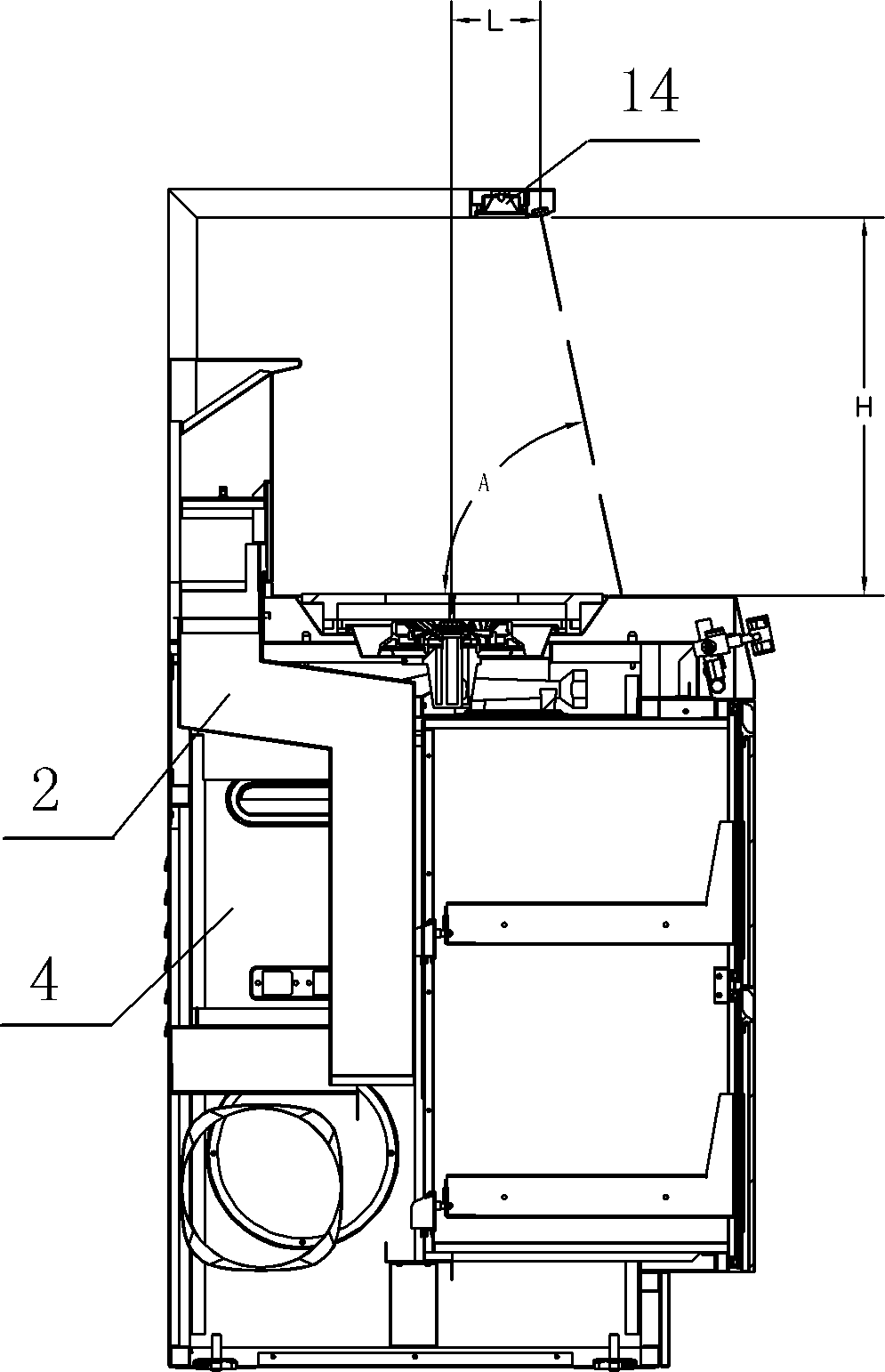

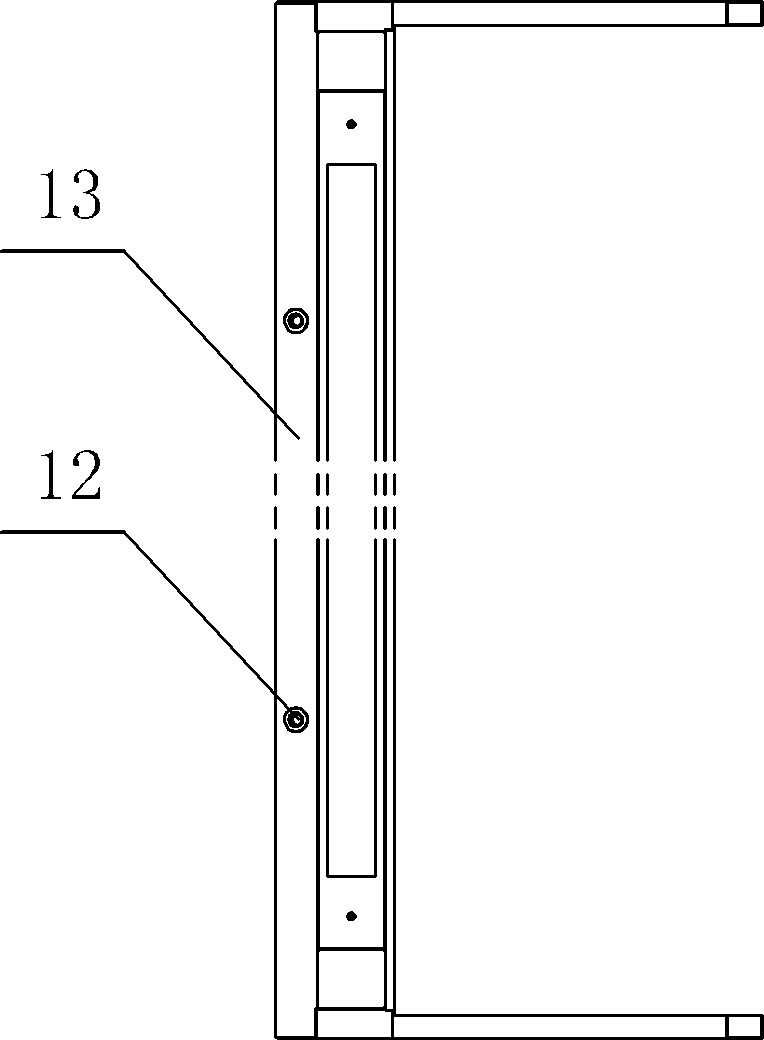

[0034] Such as figure 1 , figure 2 , image 3 As shown, the present invention is an integrated cooker with high efficiency in absorbing and exhausting oil fume, including a cooker body. The cooker body is provided with a rear side higher than the table top, and the rear side is provided with a suction port for oil fume in the direction of the cooker head. The air suction port passes through the air duct 2 is airtightly connected with fan 4.

[0035] The air inlet of the air suction port is provided with a double-arc misaligned grille, which is placed obliquely. The grille can play the role of fire prevention and flame retardant, and at the same time, it has a certain effect of oil fume separation. The grille is placed obliquely, so that the oil can flow into the air duct.

[0036] A positive pressure airflow generating device is provided for supplying air to the cooking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com