Intelligent debugging system and method used for air conditioning equipment

A technology for air conditioning equipment and debugging systems, which is applied in lighting and heating equipment, heating and ventilation control systems, heating and ventilation safety systems, etc. problems, to achieve the effect of improving the efficiency of air conditioning debugging, convenient communication between personnel, and clear project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

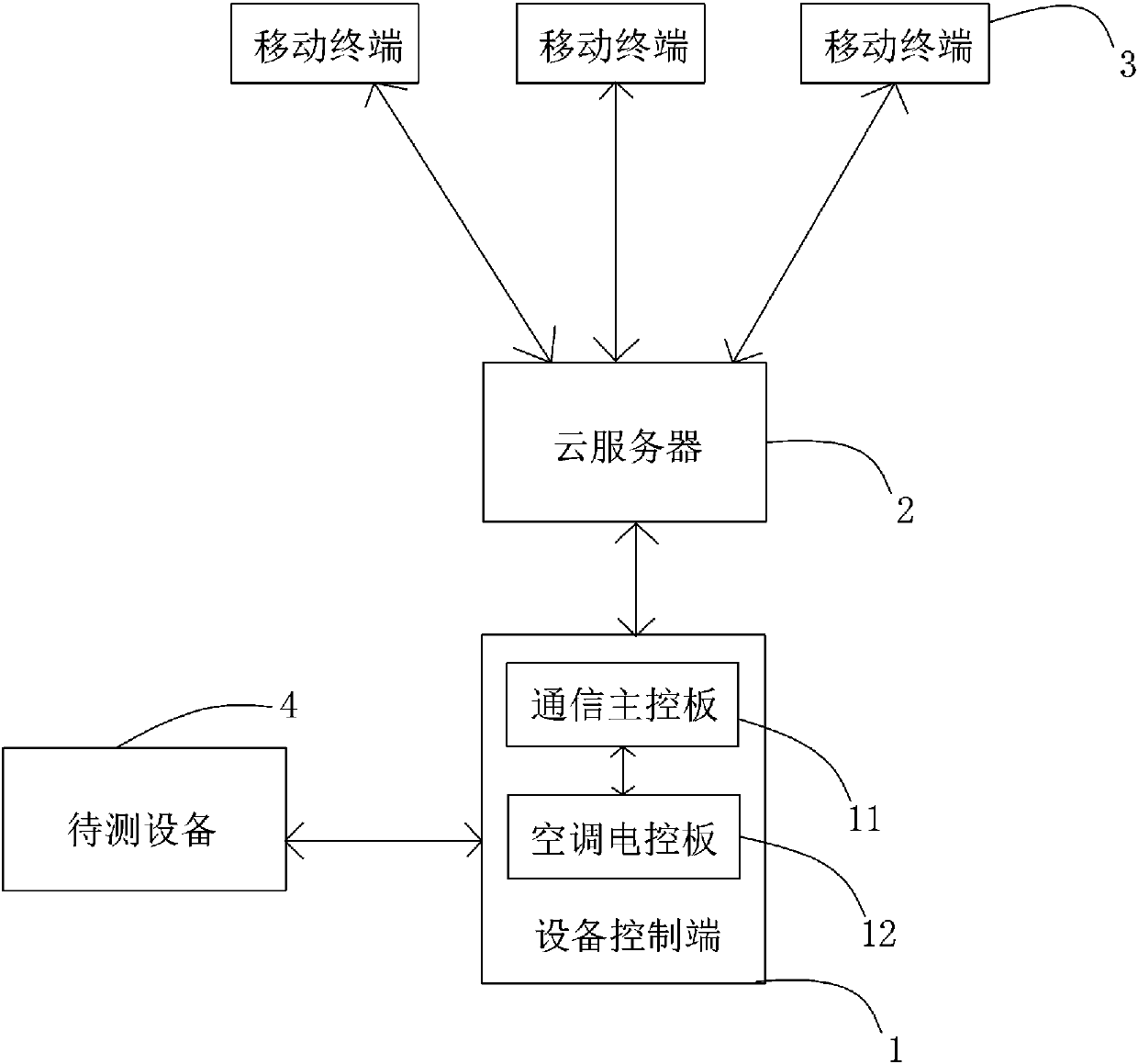

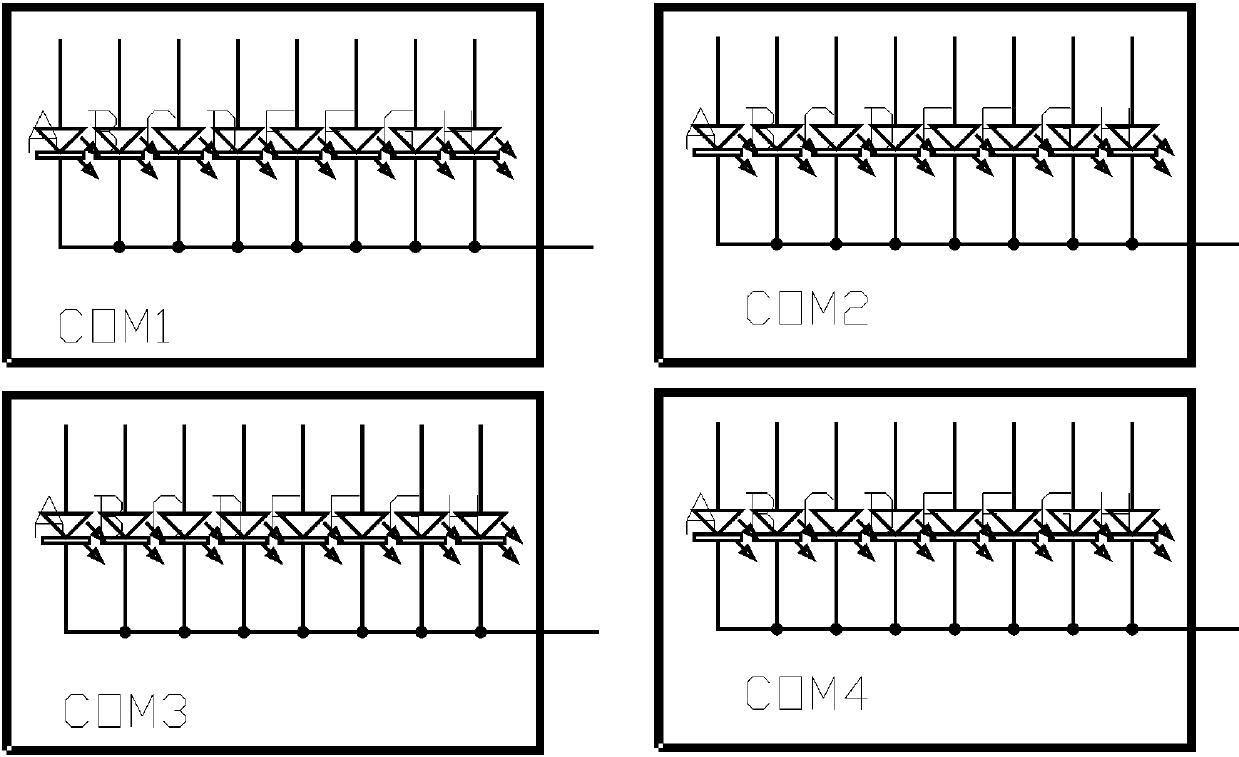

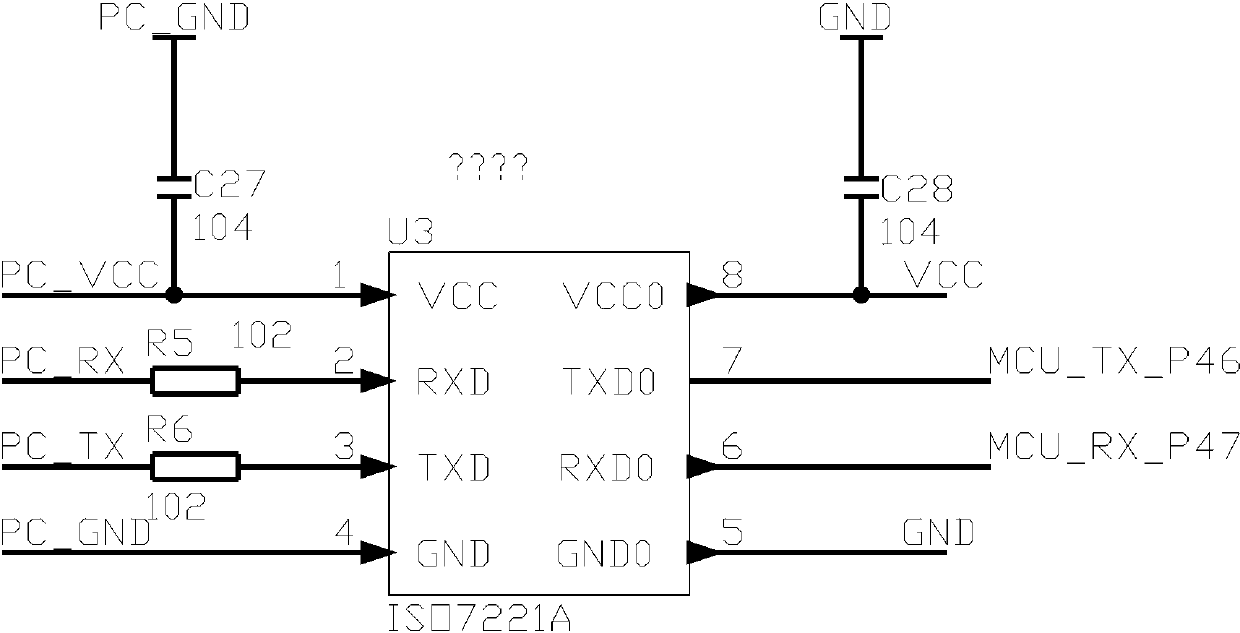

[0026] See attached Figure 1-8 , in this embodiment, an intelligent debugging system for air-conditioning equipment, including a device control terminal 1, a cloud server 2, and several mobile terminals 3, any mobile terminal 3 can be obtained through the cloud server 2 and the device control terminal 1 State information of the device under test 4, and adjust the operating status of the device under test 4, so as to achieve the purpose of real-time debugging of the device under test 4; specifically, in this embodiment, the device under test 4 is an outdoor unit of an inverter air conditioner, and the device control terminal 1 includes an air conditioner electric control board 12 and a communication main control board 11 that are installed in the outdoor unit and electrically connected to the outdoor unit components, wherein the air conditioner electric control board 12 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com