Sample preparation method for eliminating rubber membrane penetration effect of strong-weathered rock

A rubber film and strong weathering technology, which is applied in the preparation, sampling, and strength characteristics of test samples, can solve the problems of test result distortion, etc., and achieve short sample period, true and reliable triaxial shear test results, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

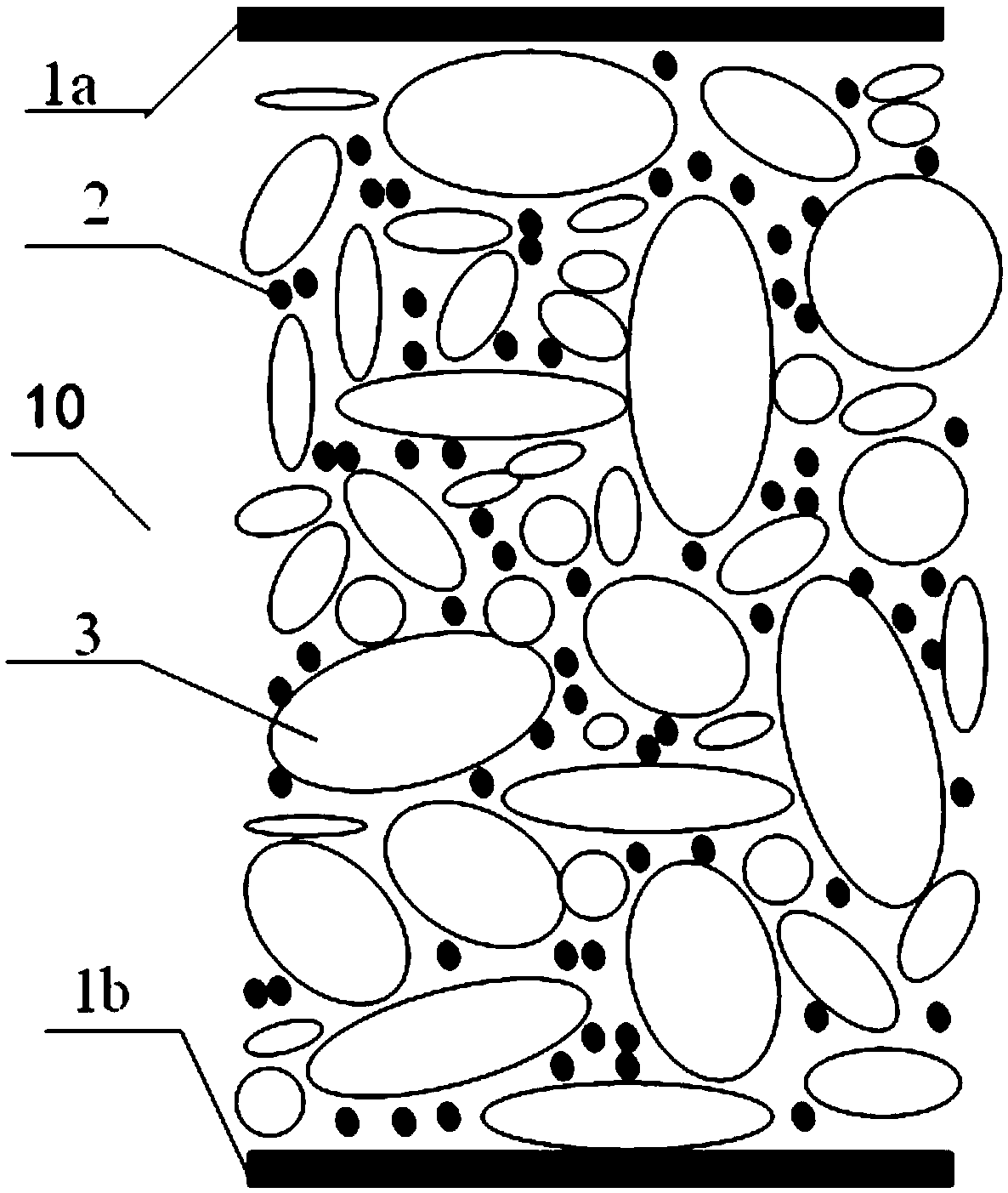

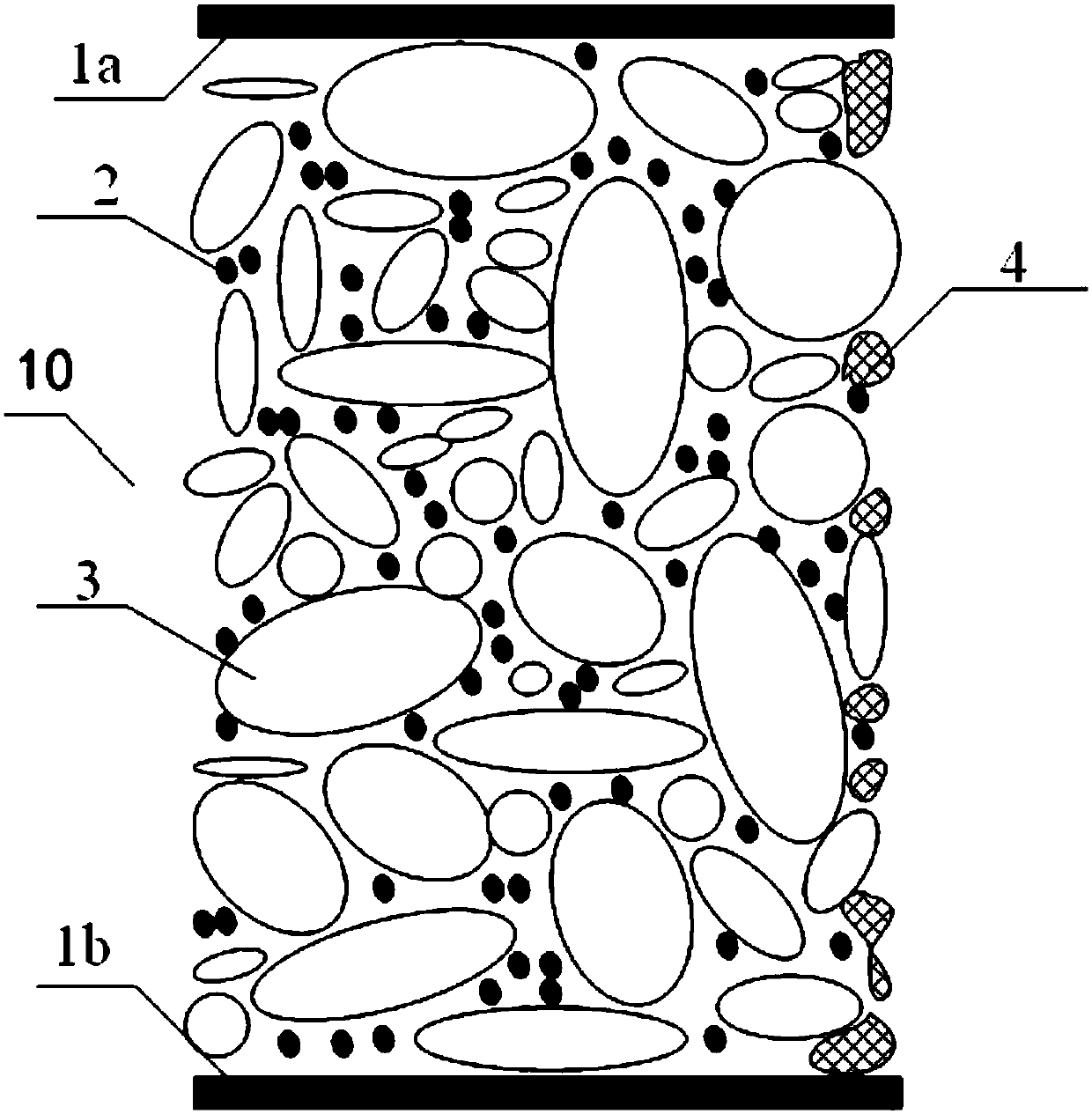

[0040] The test material of embodiment 1 is the strongly weathered granite of Xiamen City, and particle content is composed of 15.0wt% gravel, 50.0wt% sand and 35.0wt% clay, and the sample size is a standard triaxial sample (diameter 50.0mm, height 100.0mm), the sample is the undisturbed original sample, the thickness of the rubber film used is d 0 is 0.3mm, and the consolidation confining pressure is 500kPa.

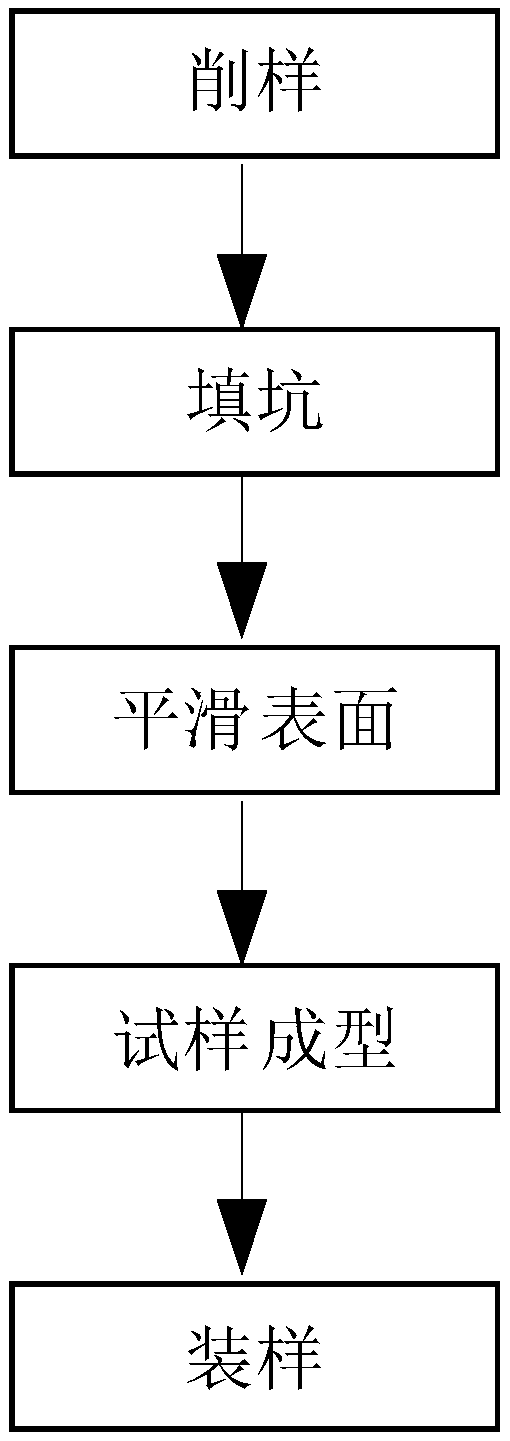

[0041] Such as figure 1 As shown, a sample preparation method to eliminate the rubber film embedding effect of strongly weathered rocks includes the following steps:

[0042] (1) Sample cutting

[0043] Take a soil column slightly larger than the size of the triaxial sample (diameter 50.0mm, height 100.0mm), first cut the soil column with a soil cutter until the height of the sample is 102.0mm, and then cut the side of the sample with a wire saw , cut the sample into a cylinder with a diameter of 50.0mm, and finally cut the sample with a wire saw to make the height o...

Embodiment 2

[0063] In order to better test the reliability and practicability of a sample preparation method that eliminates the rubber film embedding effect of strongly weathered rock of the present invention, select a test material different from the particle composition of Example 1, and the test material of Example 2 is Shenzhen The strong weathered granite in the city, the particle content is composed of 10.0wt% gravel, 45.0wt% sand and 45.0wt% clay. At the same time, in order to test the influence of sample size, rubber film thickness and consolidation confining pressure on the sample preparation method, this example adopts a different sample size and rubber film thickness from Example 1. The sample size is 38.0mm in diameter and 38.0mm in height 80.0mm, the thickness of the rubber film used is d 0 is 0.2mm, and the consolidation confining pressure is 500kPa.

[0064] Such as figure 1 As shown, a sample preparation method to eliminate the rubber film embedding effect of strongly w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com