Automatic detection device for polygonal thin-wall thin-long tubular product

An automatic detection device, a technology of slender tubes, applied in the direction of material magnetic variables, analysis of solids using sonic/ultrasonic/infrasonic waves, etc. problem, to achieve the effect of high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

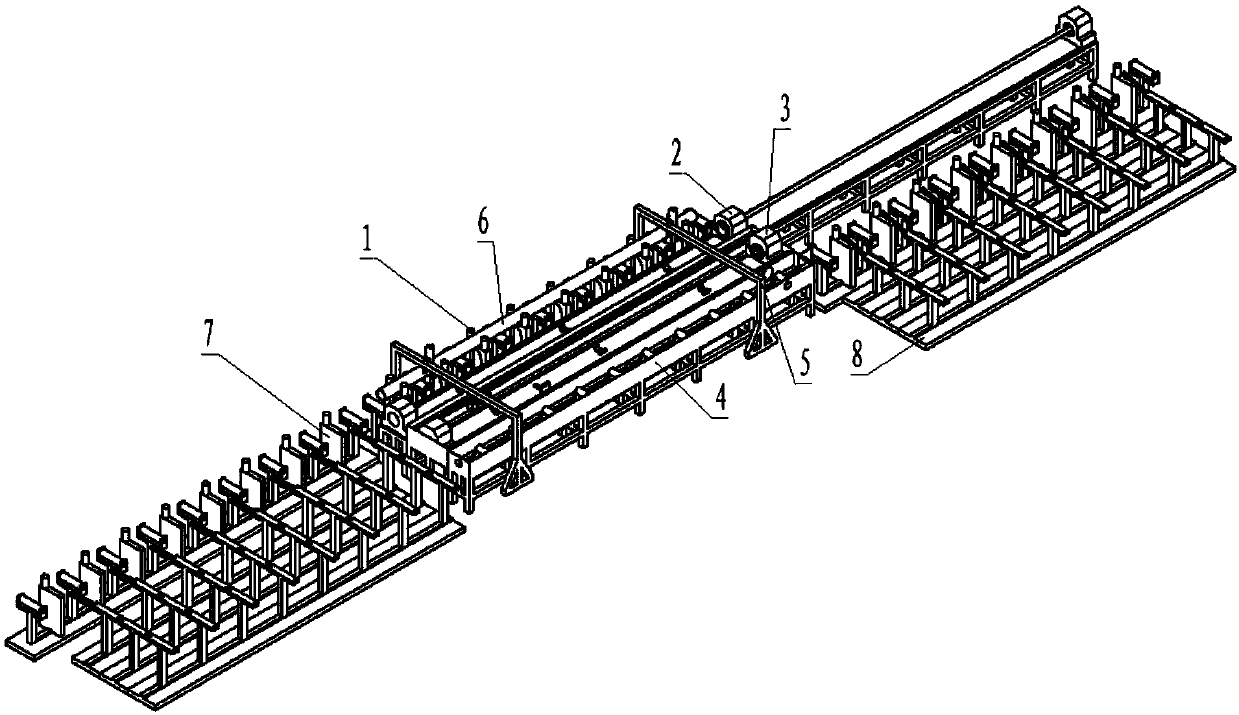

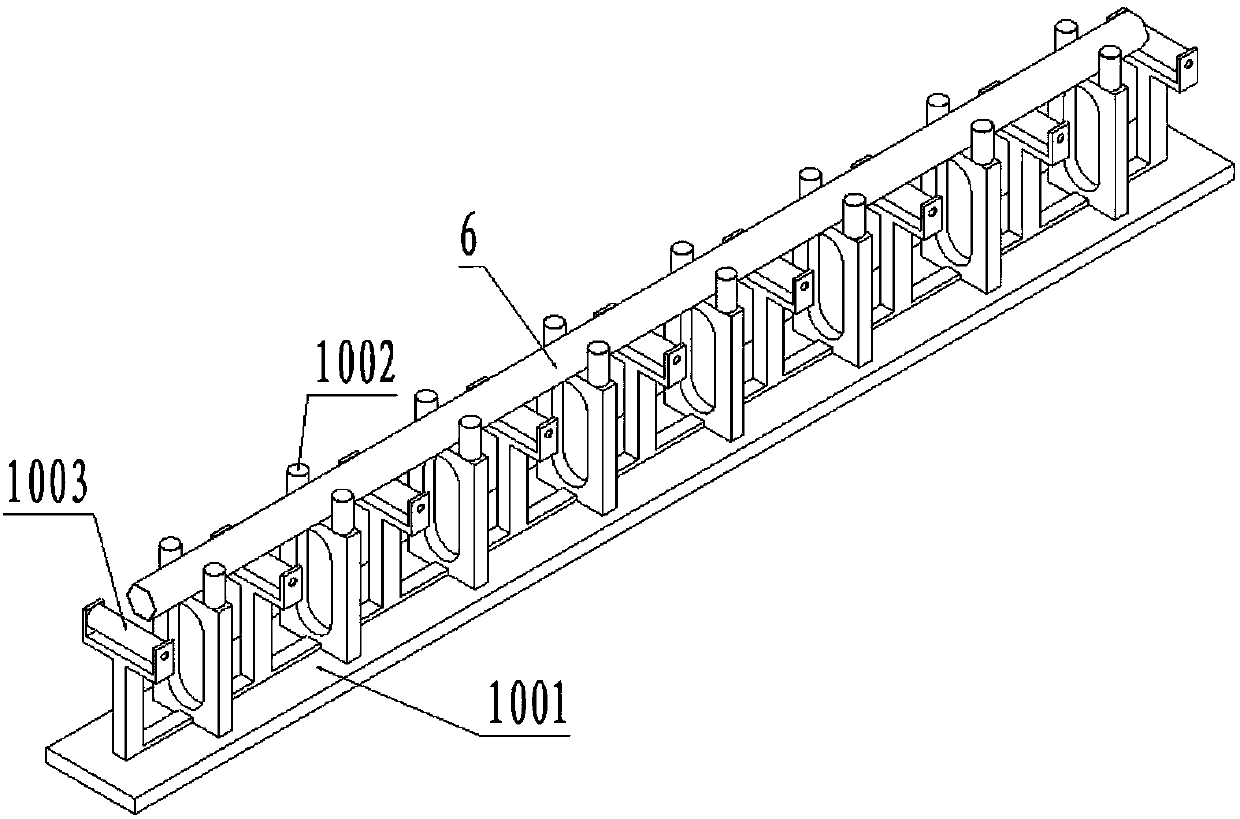

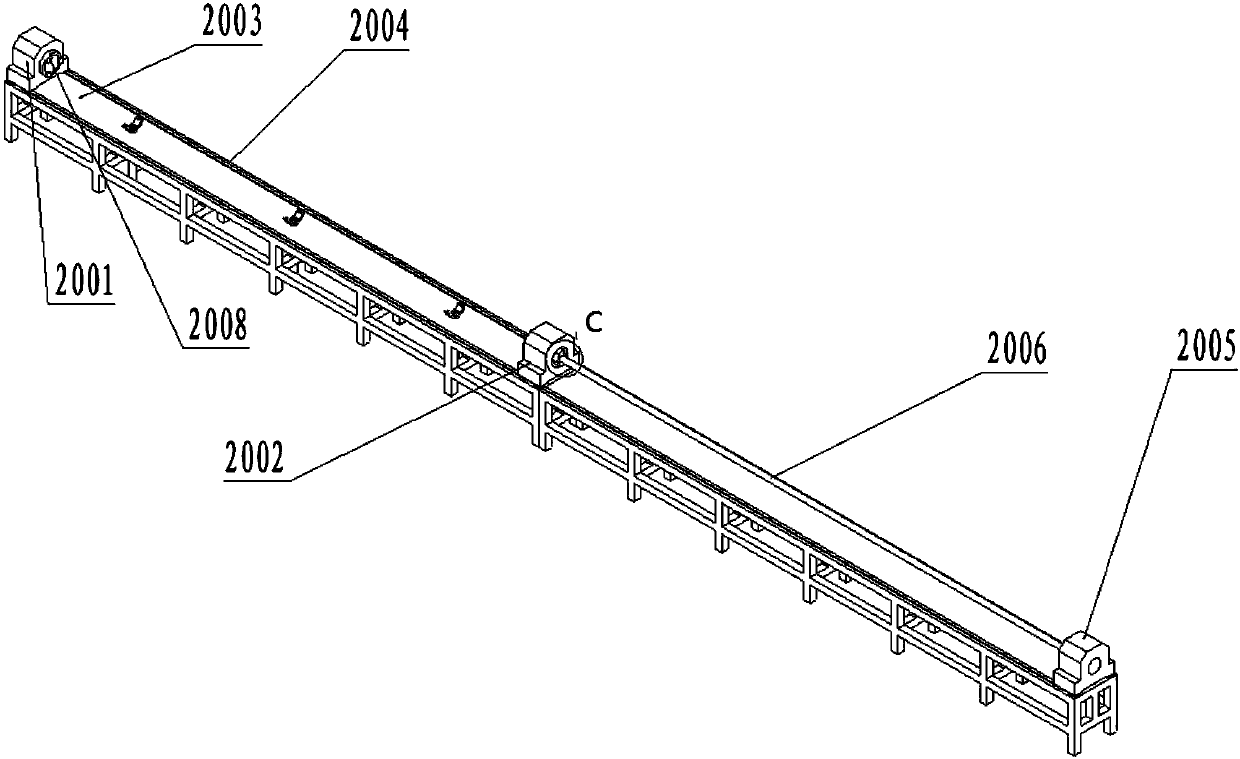

[0034] Such as figure 1 As described above, an automatic detection device for polygonal thin-walled and elongated pipes includes a storage table 1, an eddy current inner wall detection station 2, an ultrasonic and outer wall eddy current detection station 3, a drying box 4, and a translation hand 5, wherein the translation hand 5 It is installed across the side-by-side storage table 1, eddy current inner wall inspection station 2, ultrasonic and outer wall eddy current inspection station 3 and drying box 4, which can realize the inspected pipe 6 on the storage table 1 eddy current inner wall inspection station 2 , Ultrasonic and outer wall eddy current detection station 3 and drying box 4; eddy current inner wall detection station 2 can clamp and rotate the pipe 6 to be inspected, and inspect its inner wall; ultrasonic and outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com