Control method based on prediction model and controller

A predictive model and control method technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems that the PID controller cannot be realized, the control effect is optimized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

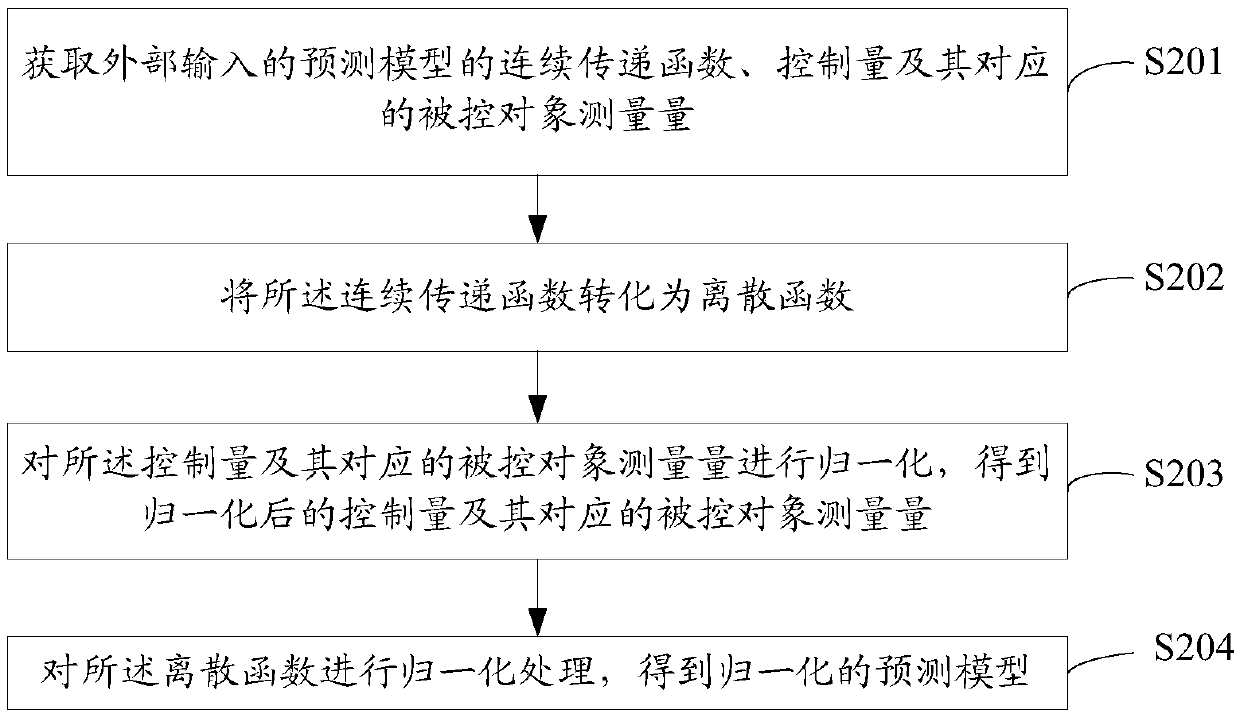

[0166] In order to solve the problems of the PID controller in the underlying control of the industrial control system described in the background section, the present application provides a predictive model-based control method suitable for the underlying controller. This method has the advantages of PID control in terms of cost, debugging and implementation, and surpasses PID control in terms of handling constraints and achieving optimization.

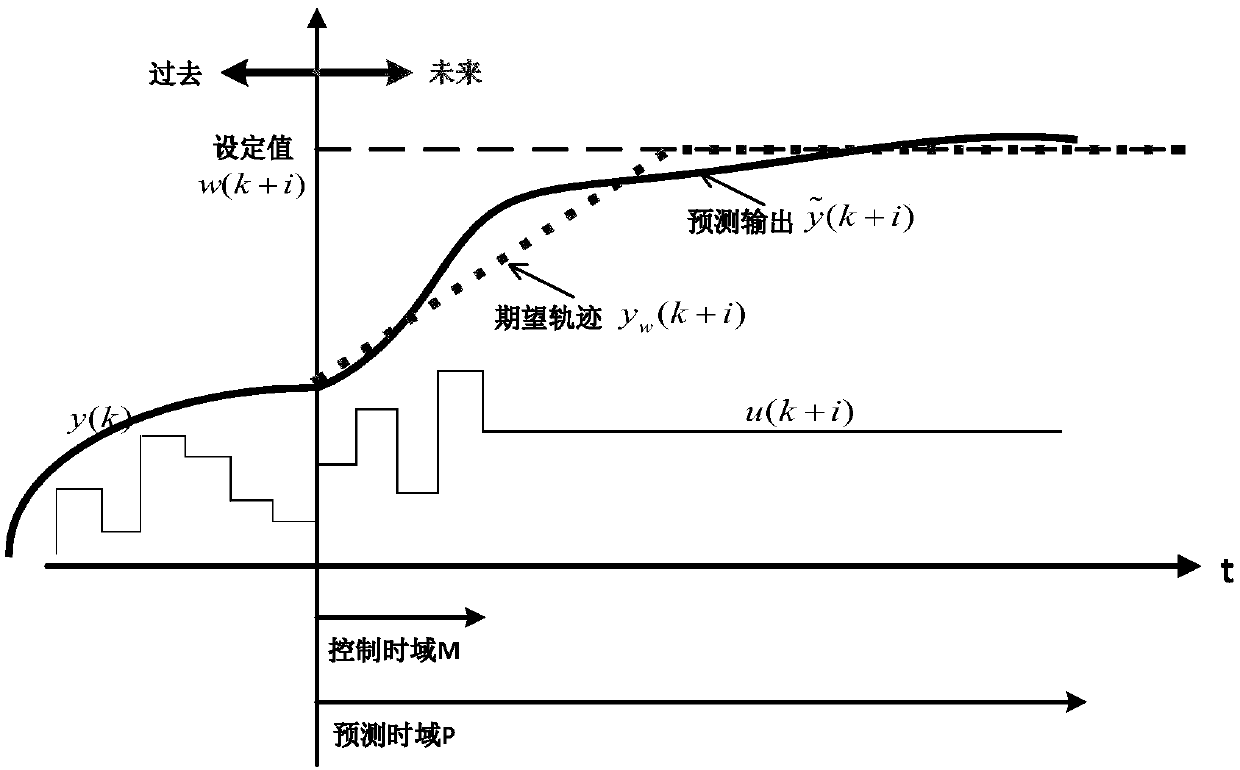

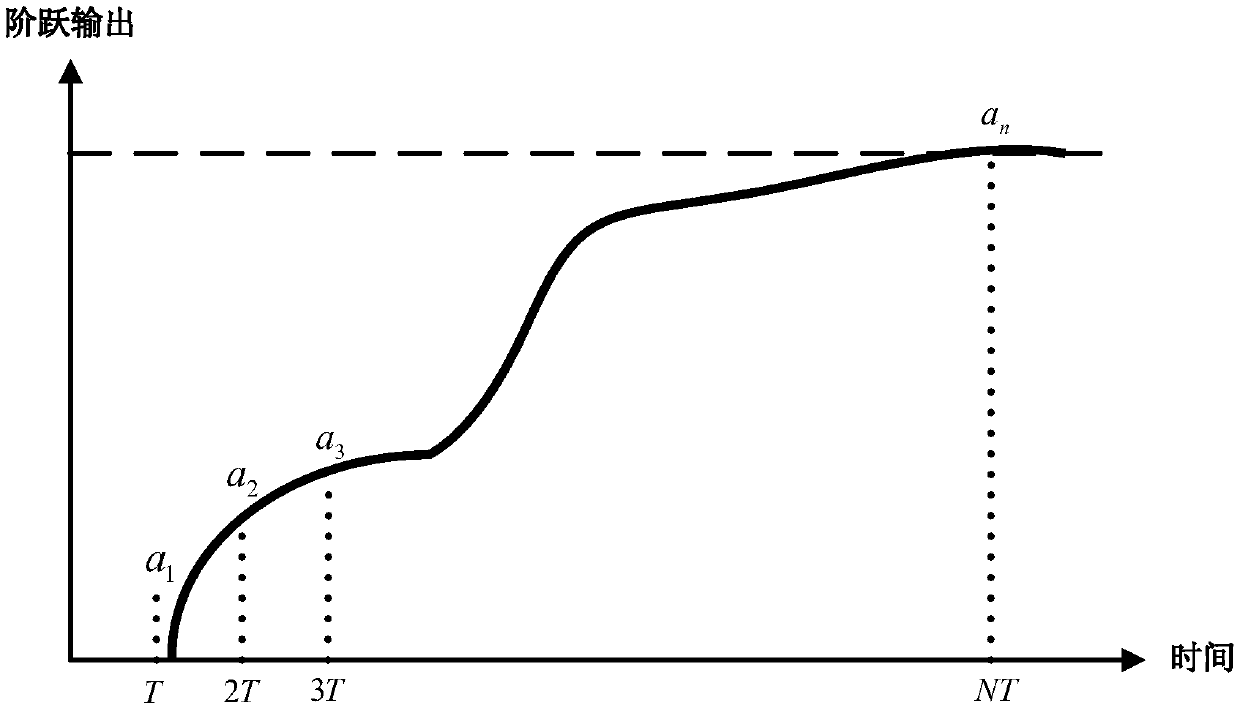

[0167] Among them, the basic idea of the control method based on the predictive model is: at the current moment, the process-based dynamic model predicts the process output of each sampling period (or at a certain interval) in a certain time domain in the future, and according to a certain optimization goal based on feedback correction The function calculates the magnitude of the control quantity in the current and future certain time domains. In order to prevent drastic changes and overshoots in the control quantity, it is generall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com