Gradient micro-porous configuration anode supporter slurry and preparation method thereof

A technology of anode support and anode slurry, which is applied in the field of green energy/electrochemistry, can solve the problems of low output power density of the battery system, and achieve the goal of ensuring effective and fast transportation, reducing concentration polarization, and increasing output power density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

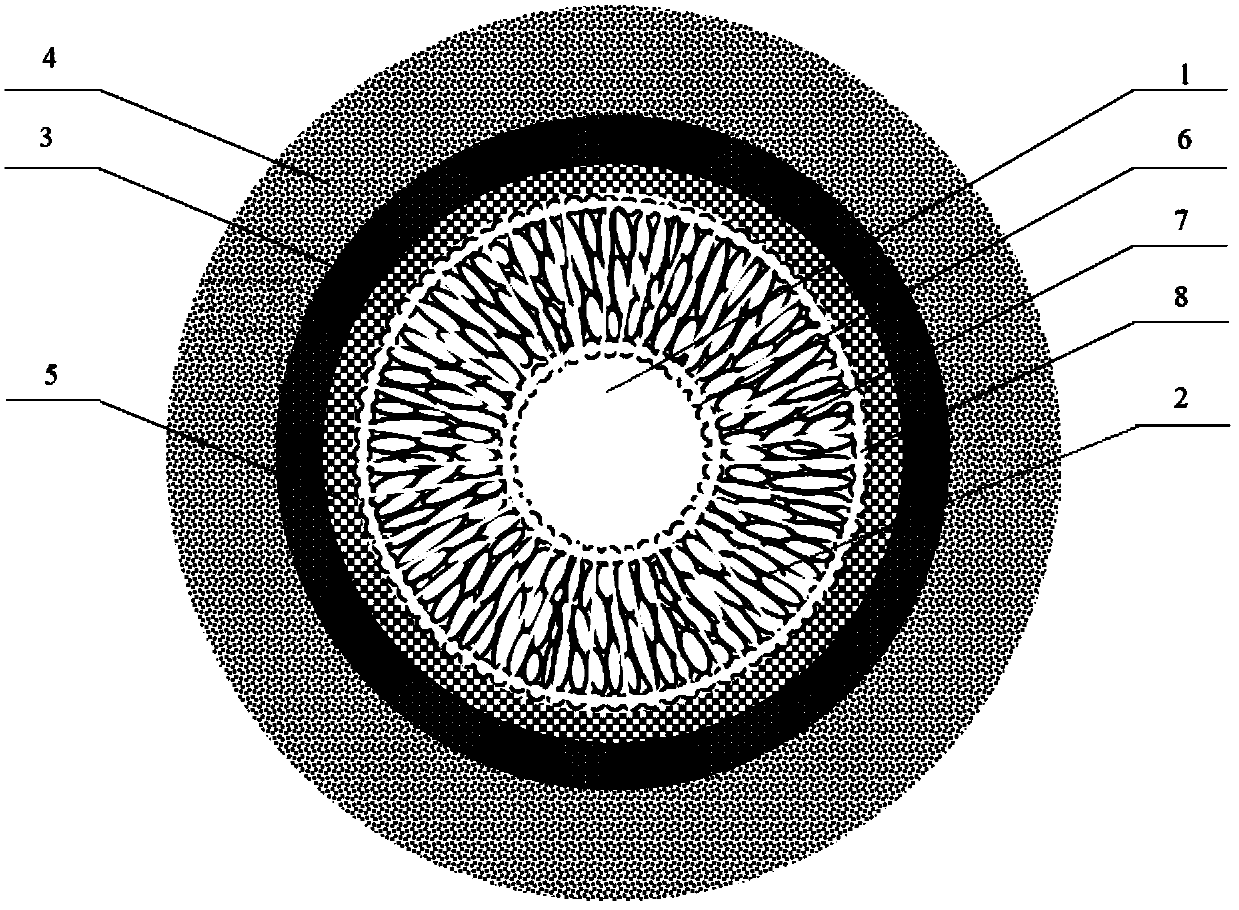

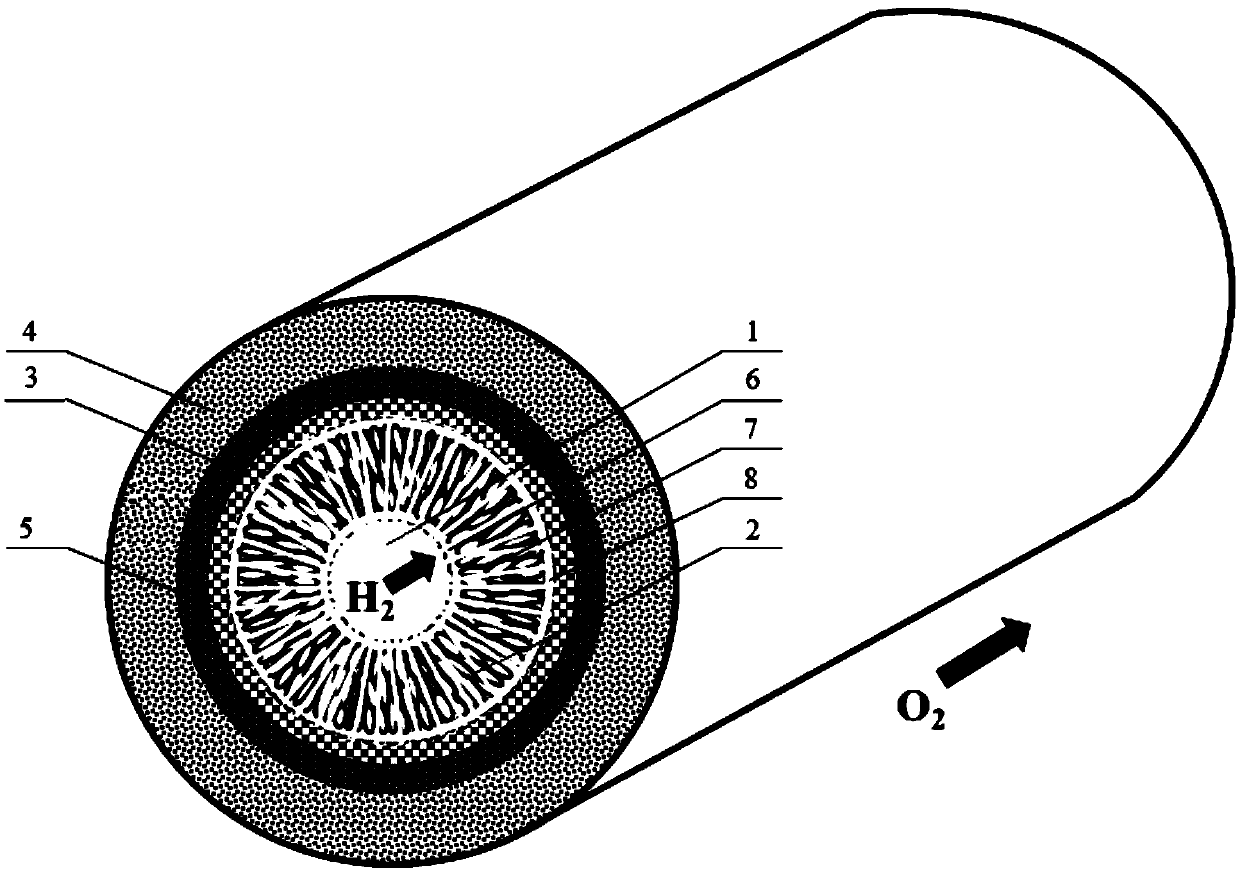

[0042] This embodiment provides a fuel cell system with high output power density, which includes from the inside to the outside: an air inlet 1, an anode support 2, an electrolyte layer 3 and a cathode 4, and also includes an anode reinforcement layer 5, the anode The reinforcing layer 5 is located between the anode support 2 and the electrolyte layer 3;

[0043] The anode support 2 has a three-layer structure, which sequentially includes an anode porous and uniform inner layer 6, an anode finger-shaped porous layer 7 and an anode porous and uniform outer layer 8 from the inside to the outside;

[0044] The air inlet 1, the anode support 2, the anode reinforcement layer 5, the electrolyte layer 3 and the cathode 4 are arranged coaxially in contact with each other in sequence.

[0045] The preparation method of the high output power density fuel cell system of this embodiment, wherein, the anode support is made of anode slurry, the anode reinforcement layer is made of anode re...

Embodiment 2

[0077] Embodiment 2: the thickness of the anode support increases

[0078] This embodiment provides a fuel cell system with high output power density, the structure of which is basically the same as that of Embodiment 1.

[0079] The preparation method of the high output power density fuel cell system of this embodiment is basically the same as that of Embodiment 1, the only difference lies in the first step.

[0080] Step 1: Preparation of the anode support:

[0081] Place the anode slurry in a vacuum degasser, and under the action of the vacuum pump, the air in the anode slurry is removed from the container through the exhaust pipe of the vacuum pump, and the vacuum degree of the container reaches 5×10 -2 bar~1×10 -1 bar, keep for 30-60 minutes to fully remove the air in the anode slurry;

[0082] Place the anode slurry after vacuum degassing in a cleaned and dried stainless steel container, immerse the anode mold with one end closed in the anode slurry after vacuum degas...

Embodiment 3

[0096] Embodiment 3: the thickness of the anode support is reduced

[0097] This embodiment provides a fuel cell system with high output power density, the structure of which is basically the same as that of Embodiment 1.

[0098] The preparation method of the high output power density fuel cell system of this embodiment is basically the same as that of Embodiment 1, the only difference lies in the first step.

[0099] Step 1: Preparation of the anode support:

[0100] Place the anode slurry in a vacuum degasser, and under the action of the vacuum pump, the air in the anode slurry is removed from the container through the exhaust pipe of the vacuum pump, and the vacuum degree of the container reaches 5×10 -2 bar~1×10 -1 bar, keep for 30-60 minutes to fully remove the air in the anode slurry;

[0101] Place the anode slurry after vacuum degassing in a cleaned and dried stainless steel container, immerse the anode mold with one end closed in the anode slurry after vacuum dega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com