Bottom-permeating water supply basin for planting sprouts

A technology for water supply basins and sprouts, applied in the field of sprouts, can solve the problems of unfavorable seed growth, inconvenient cleaning, time-consuming and laborious, etc., and achieve the effects of easy planting and growth, convenient collection, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

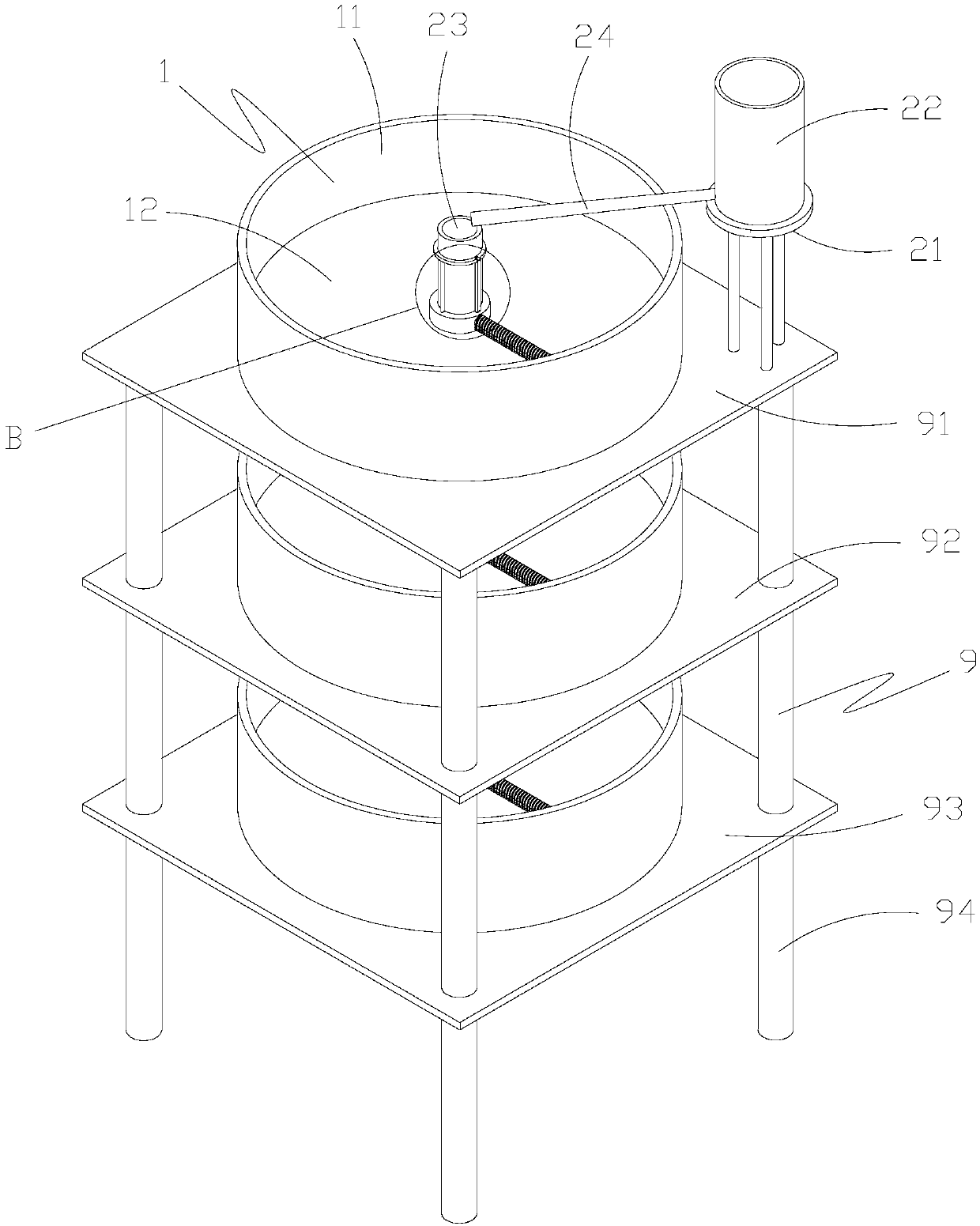

[0029] Such as Figure 6-8 Shown, a kind of bottom infiltration water supply basin that is used for the planting of sprouts comprises installation frame 9 and planting basin 1; First placement platform 91, second placement platform 92 and third placement platform 93; It is also welded on the support column and is located below the second placement platform; a planting pot is respectively installed on the first placement platform, the second placement platform and the third placement platform.

[0030] Specifically, the planting pot 1 includes a pot body 11, a permeable layer 12, a liquid supply structure, and an adjustment structure; the pot body is bolted on the placement platform to prevent the pot body from moving or falling from the placement platform; At the bottom of the body, the permeable layer is composed of clay, aggregate, porous stone and other materials, so that water can evenly infiltrate the permeable layer, so that the organic soil spread on the permeable laye...

Embodiment 2

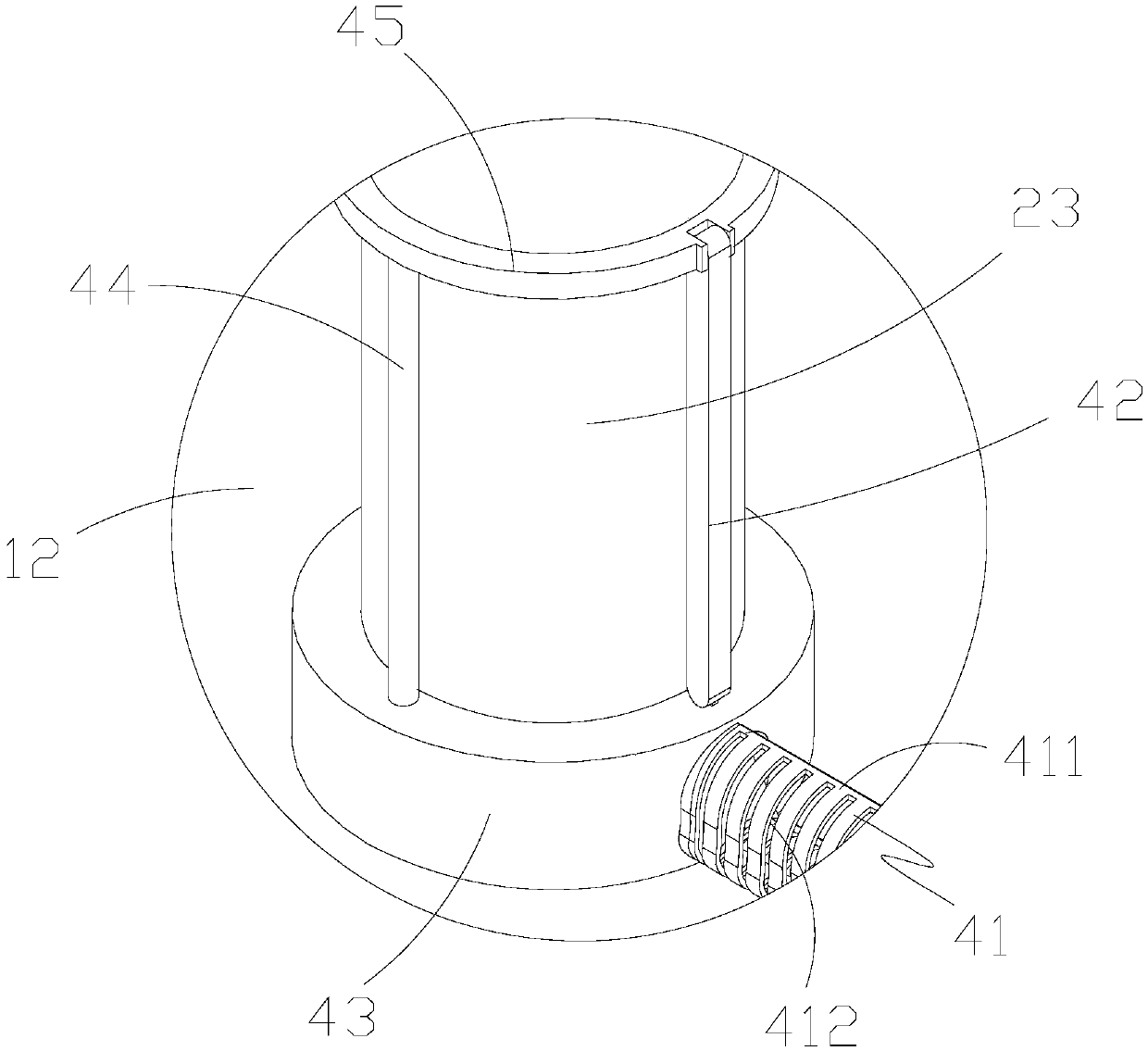

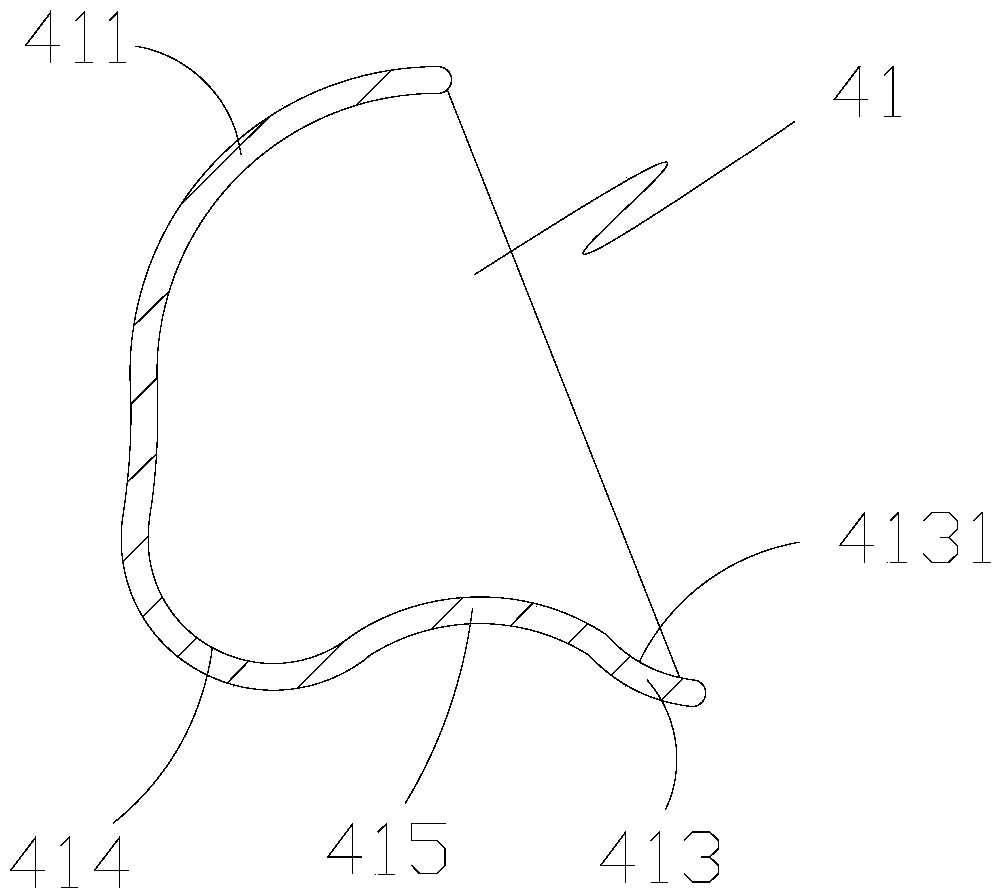

[0036] Such as Figure 1-5 As shown, the difference between this embodiment and Embodiment 1 is that a cleaning device is installed in the planting pot, and the cleaning device includes a cleaning bucket 41, a driving handle 42 and a cleaning transmission structure; the cleaning transmission structure includes a collar 43, a column 44 , sleeve shaft 45 and connecting components; the collar is set outside the water receiving pipe 23 and can rotate back and forth relative to the water receiving pipe; the column is welded on the upper surface of the collar, and the sleeve shaft is set outside the water receiving pipe and connected with the water receiving pipe bearing At the same time, the lower surface of the sleeve shaft is connected with the top screw of the column; the driving handle is installed on the sleeve shaft and connected with the hinge of the sleeve shaft; the cleaning bucket is connected with the collar through the connecting component, and the cleaning bucket is bur...

Embodiment 3

[0041] Such as Figure 9-15 As shown, the difference between this embodiment and Embodiment 2 is that a sowing device is installed, and the sowing device includes a filling bucket 61, a spreading structure and a clamping structure; At the same time, the seeds can slide down the side wall of the inclined filling bucket under the action of gravity, without additional driving force, making the structure simpler; a spreading structure is installed on the filling bucket, so that the filling can be The seeds in the bucket are evenly spread on the organic soil, so that the organic soil can be better utilized, avoiding too dense seed planting, so that the seeds can grow better, and also avoiding too sparse seed planting, ensuring once It can be planted as much as possible to increase the yield; because if the seeds are sowed manually, it is difficult to spread the seeds evenly, and because the organic soil is used for planting, it is inconvenient to move the seeds after they are sown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com