Washing base for automatically washing wiping rag in mopping robot

A mopping robot and automatic cleaning technology, used in manual floor scrubbing machinery, carpet cleaning, floor cleaning, etc., can solve the problems of secondary pollution, inconvenient cleaning of cloths, and increase the cleaning burden of users, so as to reduce the operation burden. , better effect of wiping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

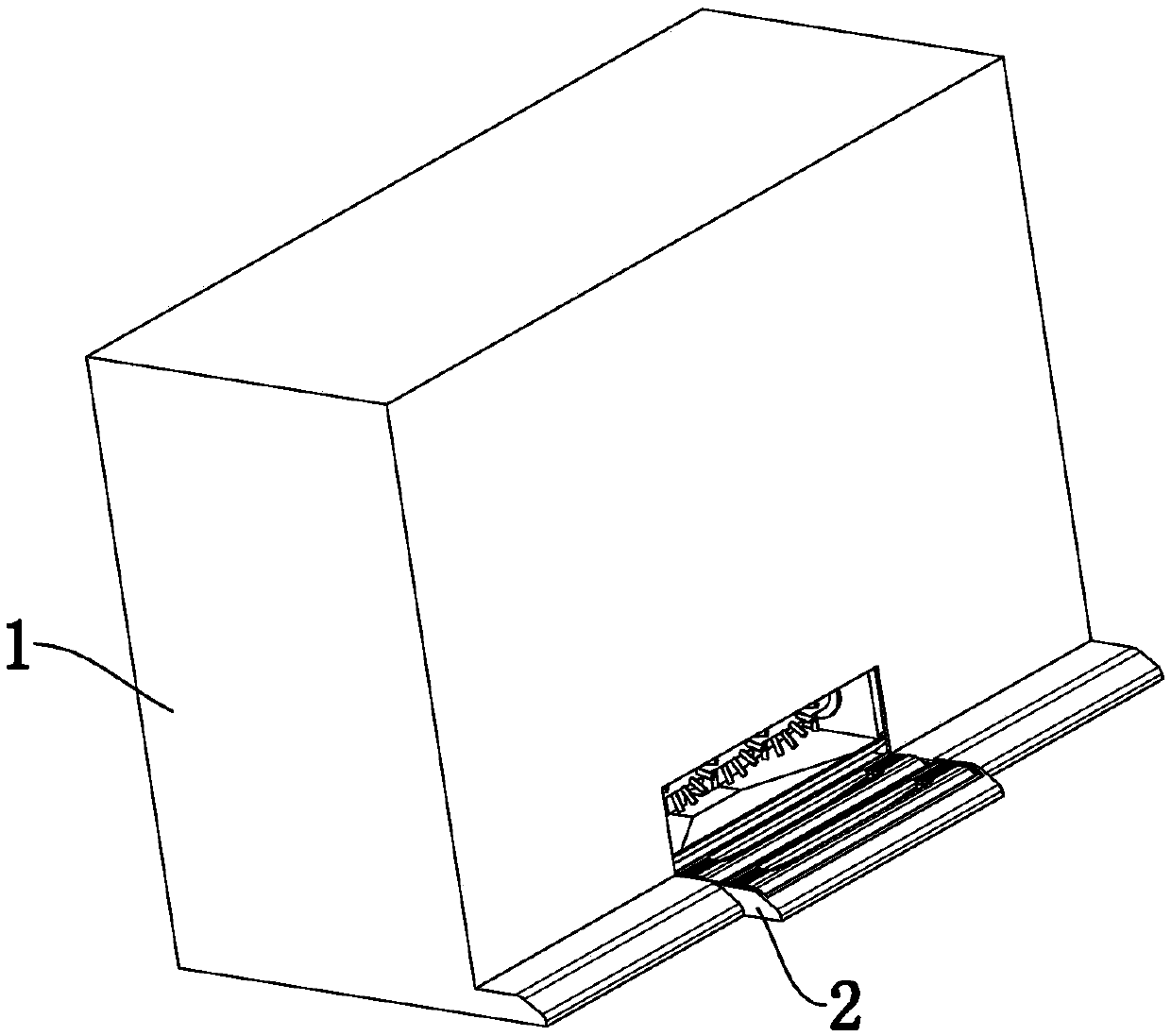

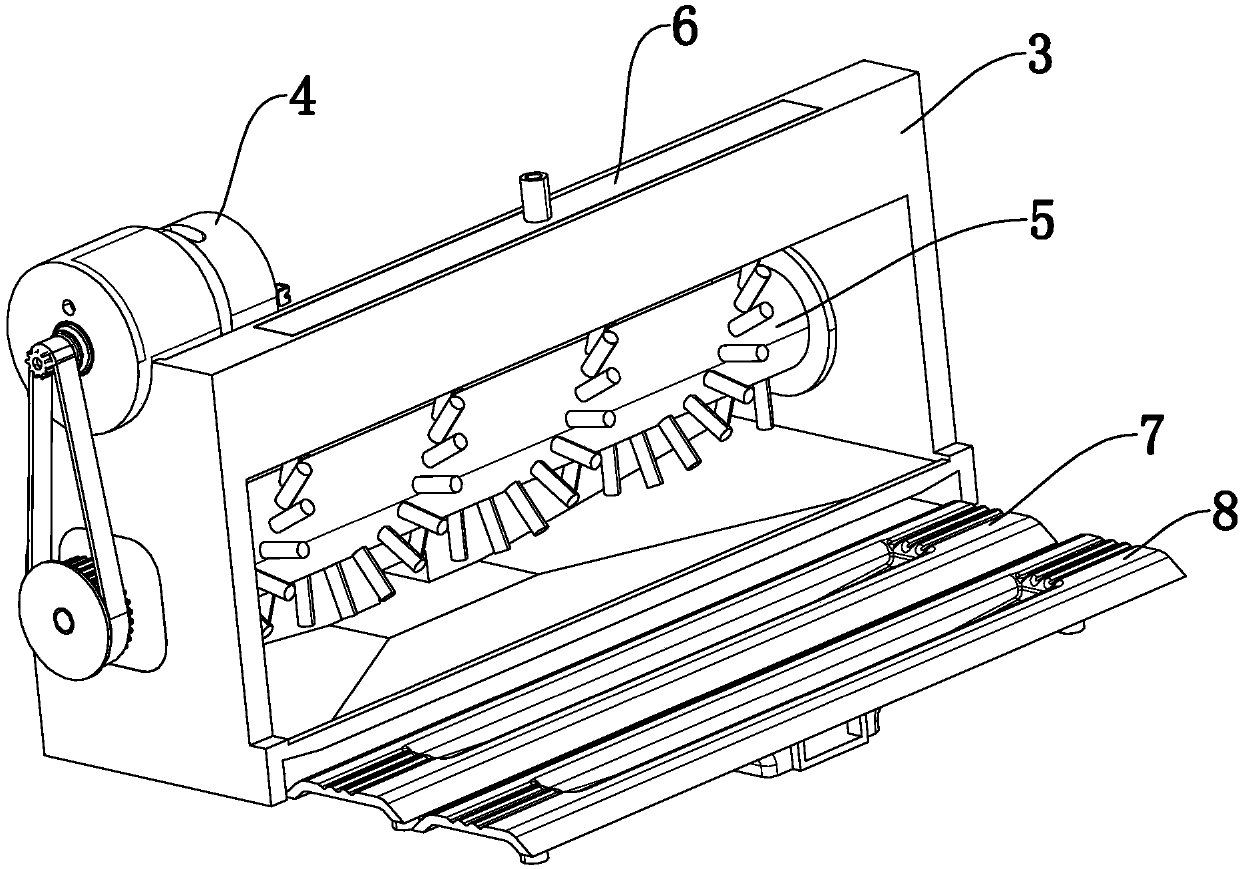

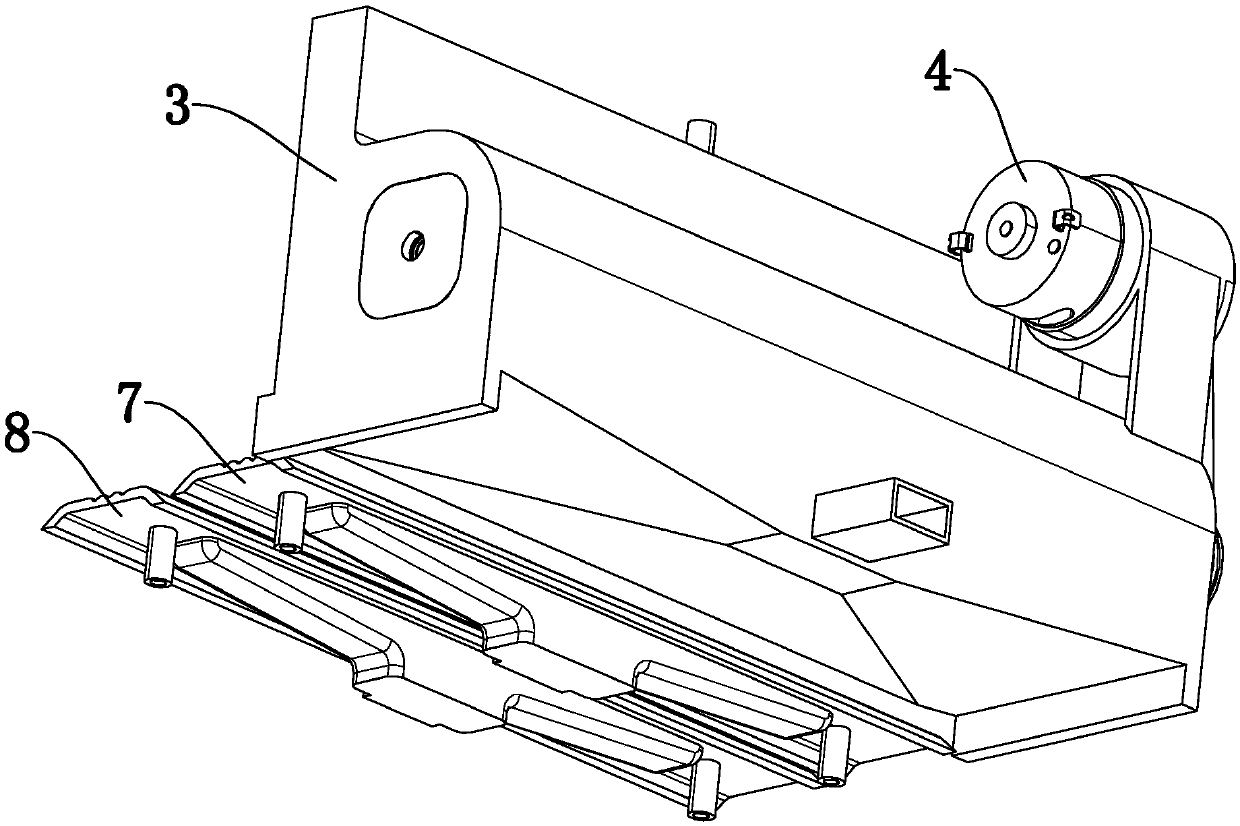

[0034] refer to Figure 1 to Figure 4 As shown in , the present embodiment provides a cleaning seat for automatically cleaning the mopping robot. The mopping robot includes a robot body 10 and a crawler-type wiper 15 arranged at the rear end of the robot body 10; wherein the cleaning seat includes:

[0035] The outer casing 1 has an opening for extending into the crawler-type wiper 15 on the front side;

[0036] Water supply mechanism, its water outlet just stretches into the side behind opening for caterpillar type wiping cloth 15;

[0037] The cleaning brush is installed in the outer casing 1 and resists against the side where the crawler-type wiper 15 extends into the opening, so as to disengage the dirt adhering to the crawler-type wiper 15 by friction.

[0038] Based on the above technical scheme, the cleaning seat used to automatically clean the mopping robot includes an outer shell 1, a water supply mechanism, and a cleaning brush, so that the robot body 10 automatical...

Embodiment 2

[0045] refer to Figure 5 As shown in , the structure and content of the cleaning seat used to automatically clean the mopping robot provided in this embodiment are basically the same as the above-mentioned embodiment 1, and the only difference is that in this embodiment, the cleaning brush is A flocking plate brush 9, the flocking plate brush 9 includes a plate portion fixed in the inner casing 3, a bristle group arranged on the front side of the plate portion, and the bristle group and the front end of the crawler-type wiper 15 stretched into the inner casing 3 offset. In addition, the flocking brush 9 can also be driven by a driving mechanism to move back and forth or up and down to enhance the decontamination effect.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap