A copper-based graphite self-lubricating composite part for low speed and heavy load and its manufacturing method

A low-speed, heavy-duty, manufacturing method technology, which is applied in the rapid manufacture of high-strength copper alloy and graphite composite parts, and the manufacture of copper-based graphite self-lubricating composite parts for low-speed and heavy-duty use, can solve the difficulty of graphite column positioning operation, copper powder and graphite Graphite powder has a large difference in density, damages the strength of the metal matrix, etc., and achieves the effects of completely controlling the content and distribution range, improving the interface bonding process, and reducing the splitting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A rapid manufacturing method for copper-based graphite self-lubricating composites for low-speed and heavy-duty use. The graphite column is composed of natural flake graphite and SiC; the copper alloy is composed of Cu, Sn, Al 2 o 3 , Zn composition, the purity is greater than 99.5%, of which Sn accounts for 1% of the copper alloy mass fraction, Al 2 o 3 The mass fraction of the copper alloy is 0.3%, Zn is 1% of the copper alloy mass fraction, and the rest is Cu.

[0043] The specific preparation steps are as follows: (1) Design and preparation of graphite core

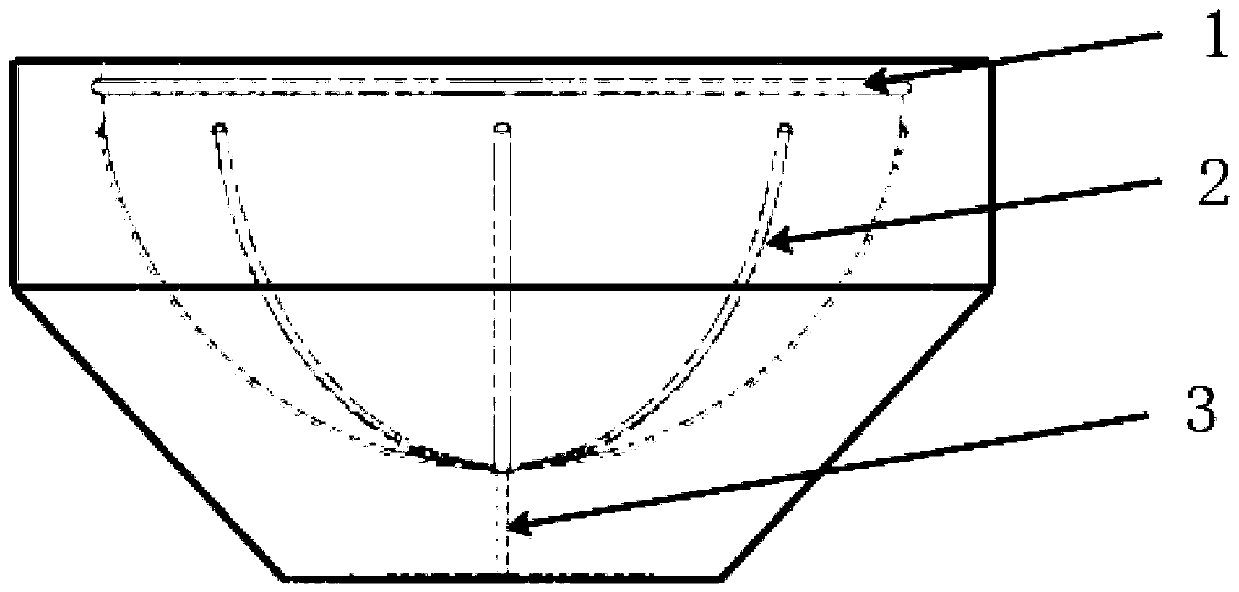

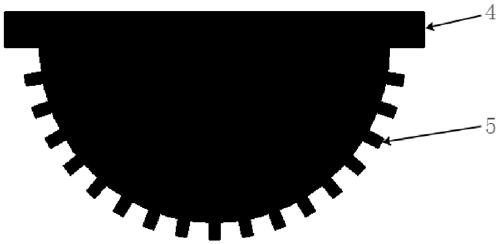

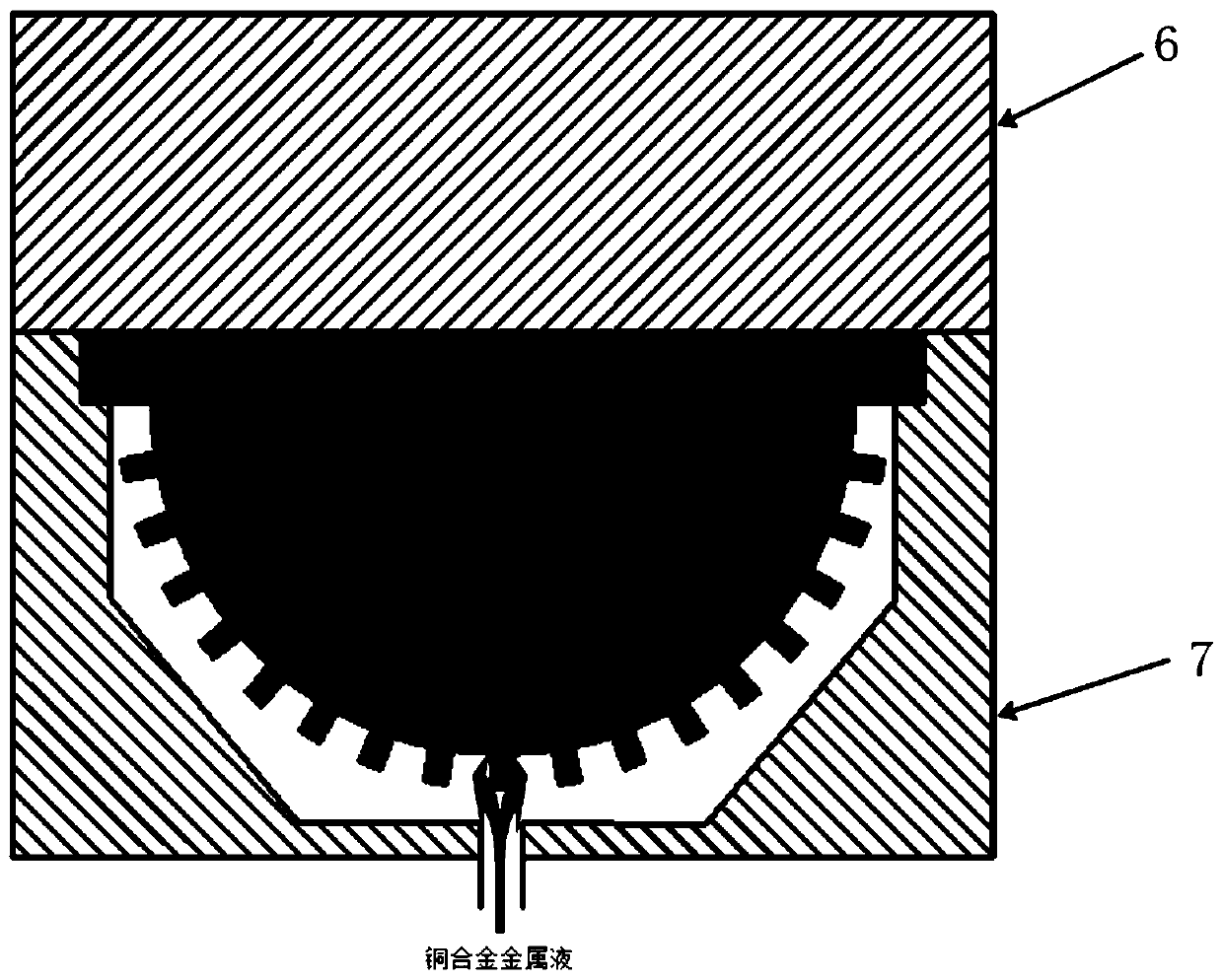

[0044] The graphite core structure is designed according to the requirements of the formation and transfer mechanism of the graphite lubricating film. The graphite columns are distributed in the normal direction of the graphite matrix, and there is a certain overlap along the friction direction. The sum of the friction areas accounts for 20% of the entire friction surface area. The diameter of the graphite c...

Embodiment 2

[0053] A rapid manufacturing method for copper-based graphite self-lubricating composites for low-speed and heavy-duty use. The graphite column is composed of natural flake graphite and SiC; the copper alloy is composed of Cu, Sn, Al 2 o 3 , Zn composition, the purity is greater than 99.5%, of which Sn accounts for 1.5% of the copper alloy mass fraction, Al 2 o 3 The mass fraction of copper alloy is 0.6%, Zn is 1.3% of copper alloy, and the rest is Cu.

[0054] Concrete preparation steps are as follows:

[0055] (1) Design and preparation of graphite core

[0056] The graphite core structure is designed according to the requirements of the formation and transfer mechanism of the graphite lubricating film. The graphite columns are distributed in the normal direction of the graphite matrix and overlap along the friction direction to a certain extent. The sum of the friction areas accounts for 25% of the entire friction surface area. The diameter of the graphite column is 7mm...

Embodiment 3

[0065] A rapid manufacturing method for copper-based graphite self-lubricating composites for low-speed and heavy-duty use. The graphite column is composed of natural flake graphite and SiC; the copper alloy is composed of Cu, Sn, Al 2 o 3 , Zn composition, the purity is greater than 99.5%, of which Sn accounts for 2% of the copper alloy mass fraction, Al 2 o 3 The mass fraction of the copper alloy is 0.8%, Zn is 1.7% of the copper alloy mass fraction, and the rest is Cu.

[0066] Concrete preparation steps are as follows:

[0067] (1) Design and preparation of graphite core

[0068] The graphite core structure is designed according to the requirements of the formation and transfer mechanism of the graphite lubricating film. The graphite columns are distributed in the normal direction of the graphite matrix and overlap along the friction direction to a certain extent. The sum of the friction areas accounts for 30% of the entire friction surface area. The diameter of the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com