Novel stable welding machine

A welding machine, stable technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unstable welding quality, rough welding parts quality, rising manufacturing cost, etc., to achieve the welding process. Simple and convenient, meet the needs of welding, use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

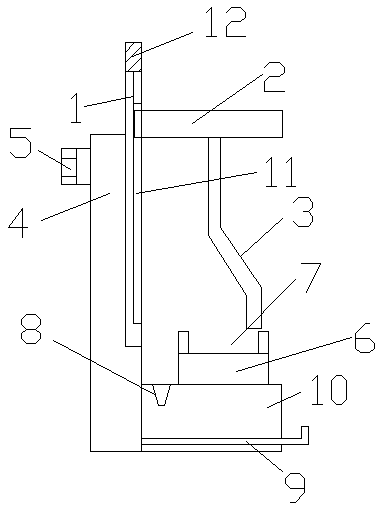

[0012] A new type of stable welding machine is provided with a movable rod 1, a top cover 2 is arranged on the movable rod 1, a movable welding head 3 is arranged below the ejector rod 1, and beside the movable rod 1 A support rod 4 is provided, and a motor 5 is arranged on the support rod 4. The motor 5 drives the movable welding head 3 to move, and the bottom end of the support rod 4 is provided with a processing table 6. During the processing A positioning plate 7 is arranged inside the table 6 , and chip relief grooves 8 are arranged on both sides of the processing table 6 .

[0013] A blanking plate 9 is arranged under the chip relief groove 8, and the blanking plate 9 is located at the lower end of the processing table.

[0014] A blanking cavity 10 is arranged under the processing table 6, and the blanking plate 9 is movably inserted into the blanking cavity 10.

[0015] The movable rod 1 is provided with a movable groove 11, and the top cover 2 is embedded in the mova...

Embodiment 2

[0017] A new type of stable welding machine is provided with a movable rod 1, a top cover 2 is arranged on the movable rod 1, a movable welding head 3 is arranged below the ejector rod 1, and beside the movable rod 1 A support rod 4 is provided, and a motor 5 is arranged on the support rod 4. The motor 5 drives the movable welding head 3 to move, and the bottom end of the support rod 4 is provided with a processing table 6. During the processing A positioning plate 7 is arranged inside the table 6 , and chip relief grooves 8 are arranged on both sides of the processing table 6 .

[0018] A blanking plate 9 is arranged under the chip relief groove 8, and the blanking plate 9 is located at the lower end of the processing table.

[0019] A blanking cavity 10 is arranged under the processing table 6, and the blanking plate 9 is movably inserted into the blanking cavity 10.

[0020] The movable rod 1 is provided with a movable groove 11, and the top cover 2 is embedded in the mova...

Embodiment 3

[0023] A new type of stable welding machine is provided with a movable rod 1, a top cover 2 is arranged on the movable rod 1, a movable welding head 3 is arranged below the ejector rod 1, and beside the movable rod 1 A support rod 4 is provided, and a motor 5 is arranged on the support rod 4. The motor 5 drives the movable welding head 3 to move, and the bottom end of the support rod 4 is provided with a processing table 6. During the processing A positioning plate 7 is arranged inside the table 6 , and chip relief grooves 8 are arranged on both sides of the processing table 6 .

[0024] A blanking plate 9 is arranged under the chip relief groove 8, and the blanking plate 9 is located at the lower end of the processing table.

[0025] A blanking cavity 10 is arranged under the processing table 6, and the blanking plate 9 is movably inserted into the blanking cavity 10.

[0026] The movable rod 1 is provided with a movable groove 11, and the top cover 2 is embedded in the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com