A fully automatic film laminating machine

A fully automated, film laminating machine technology, applied in the field of adapter pin detection, can solve the problems of unsightly film on the surface of the product, uneven pasting quality, high labor cost, etc., to save manpower, improve position accuracy, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

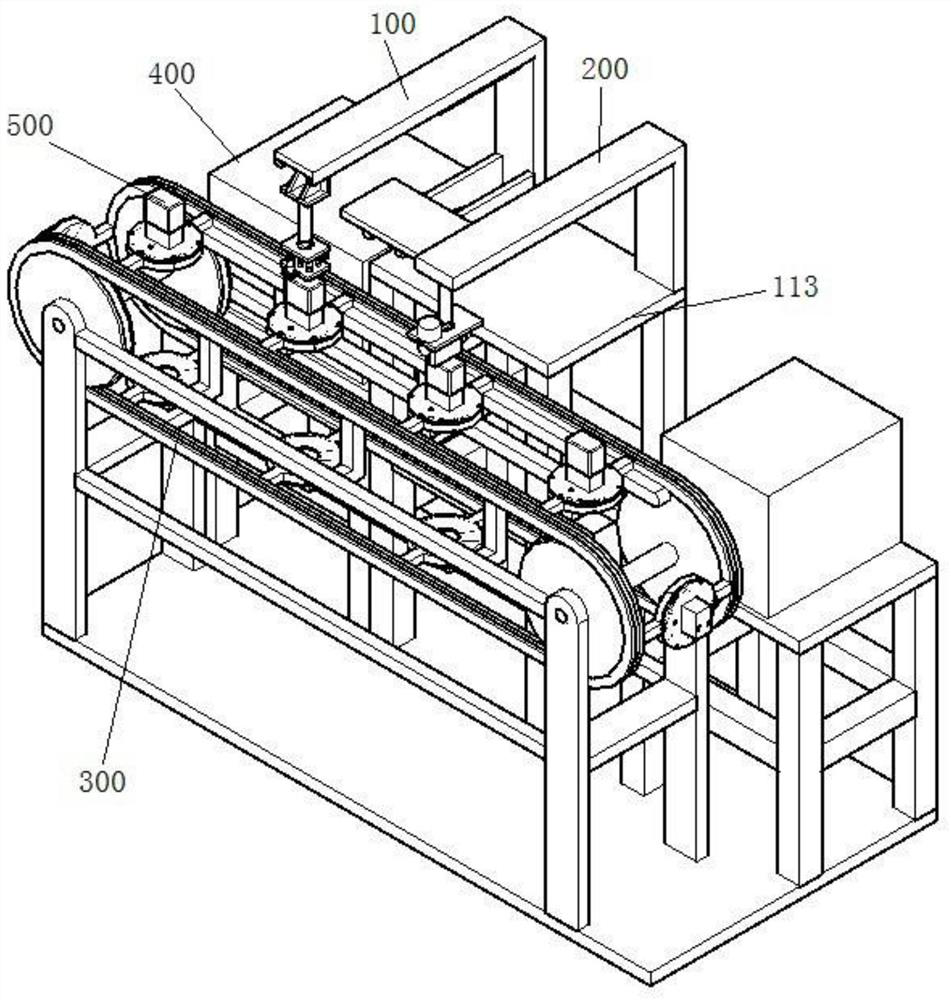

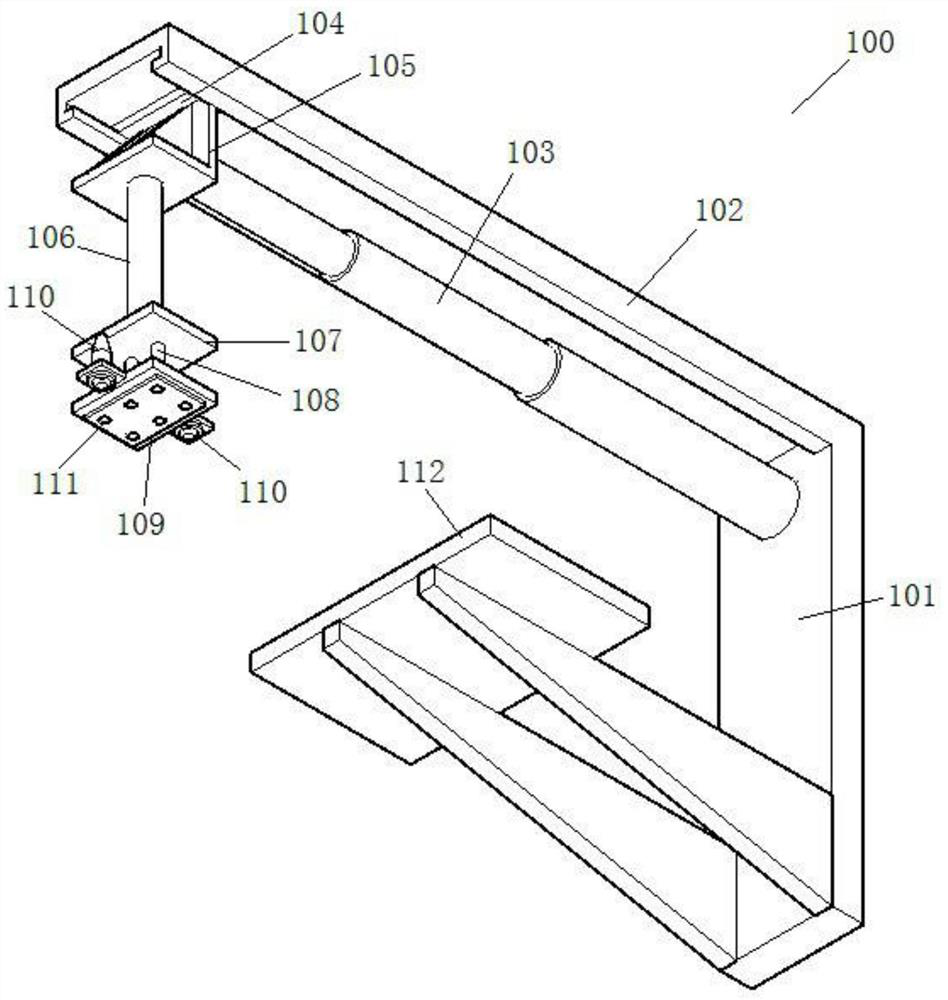

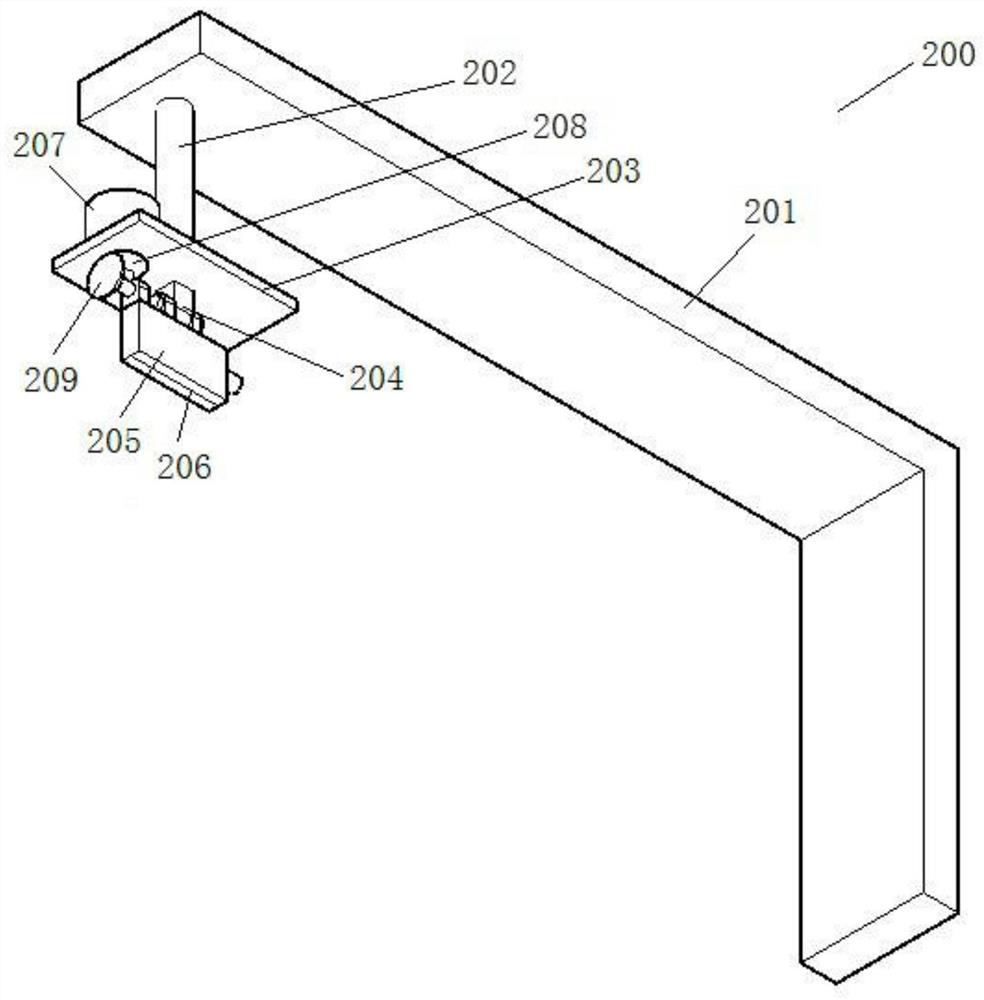

[0023] Such as Figure 1 to Figure 4 As shown, a fully automatic film laminating machine, the film laminating machine includes:

[0024] The film sticking device 100 is used to absorb the protective film and stick it on the surface of the product 500;

[0025] The film blowing device 200 squeezes out the air between the protective film and the product 500 by blowing out high-pressure gas, avoiding the existence of air bubbles on the surface of the protective film and the product 500, so that the protective film is firmly pasted on the surface of the product 500;

[0026] The product conveying device 300 is used to convey the product 500 through the film sticking device 100 and the film blowing device 200 in sequence;

[0027] The industrial computer 400 is installed with the edited control software in the industrial computer, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com