Connection structure of semitrailer aluminum vehicle frame and steel traction plate

A technology for connecting structures and traction plates, applied in the direction of traction connectors, substructures, vehicle components, etc., can solve the problems of unfavorable traction pin stress dispersion, low production efficiency, weld cracking, etc., to reduce the risk of weld cracking and improve The effect of production efficiency, assembly and maintenance replacement convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of the present invention, the following will describe the present invention more fully. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. On the contrary, these embodiments are provided to make the understanding of the disclosure of the present invention more thorough and comprehensive.

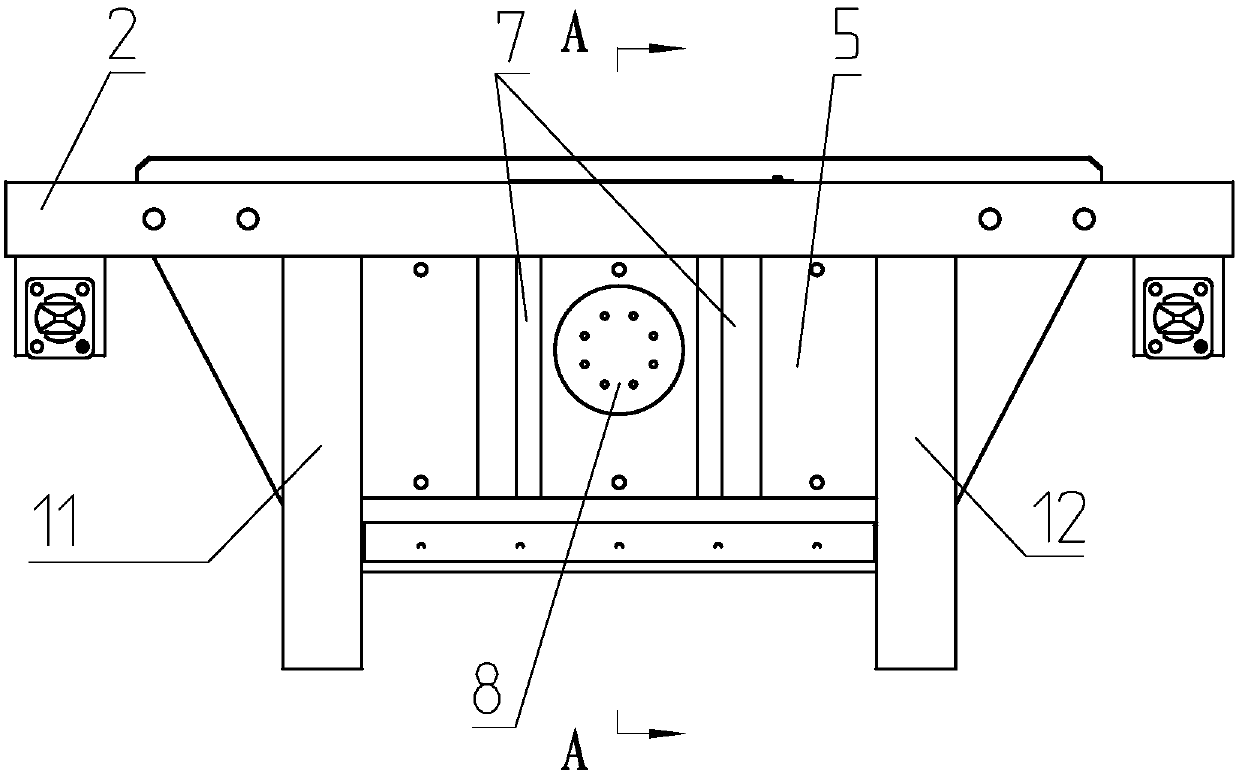

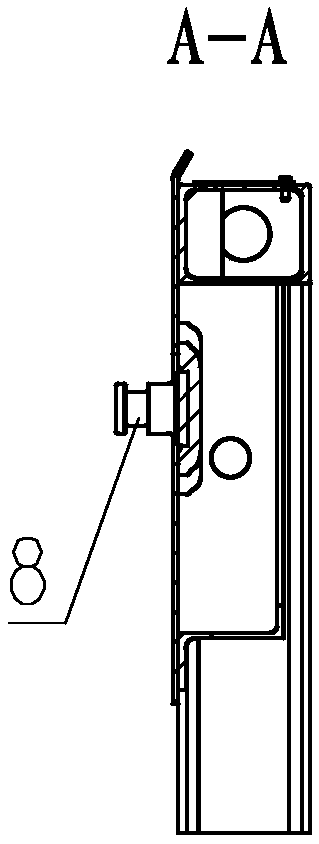

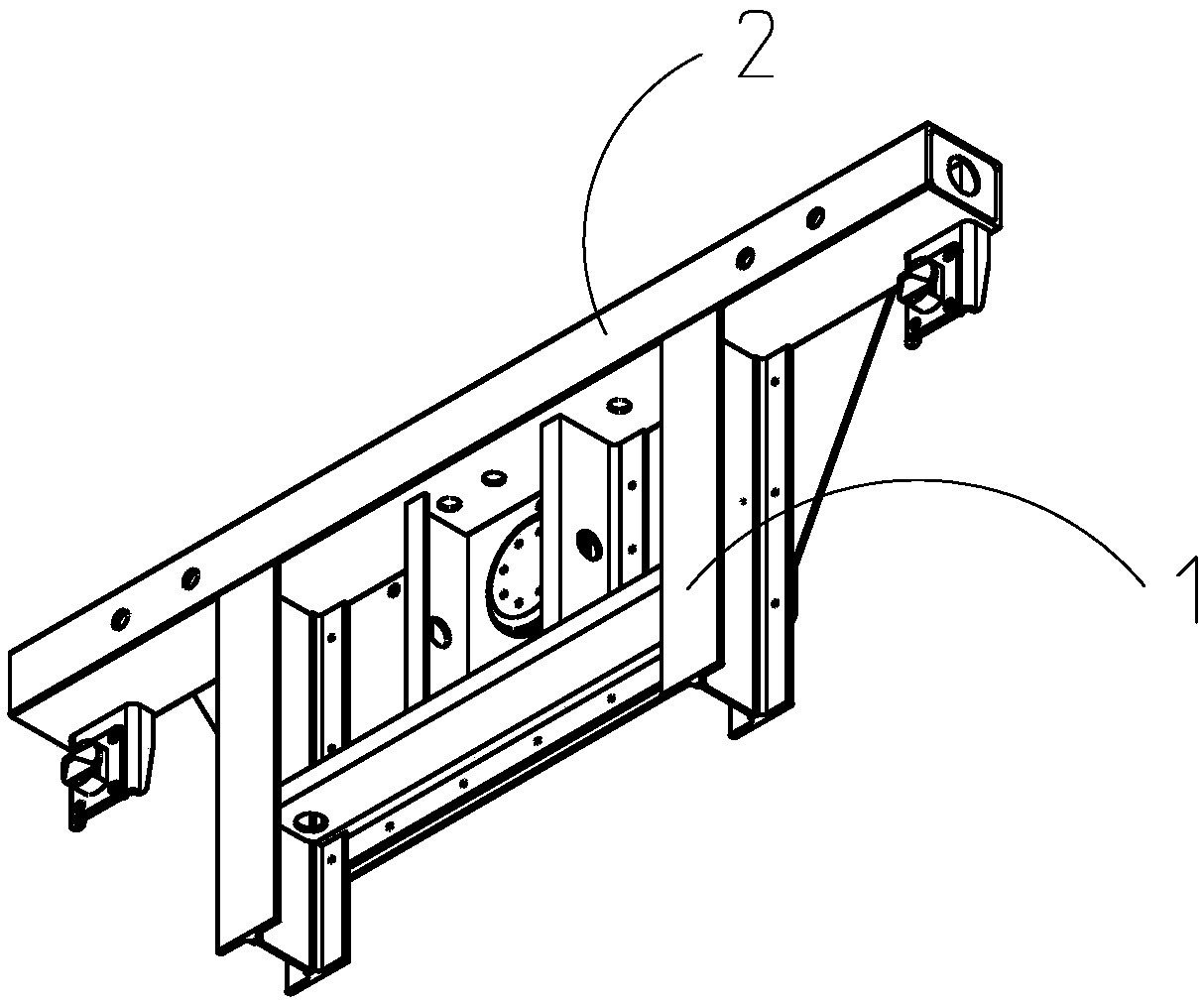

[0032] refer to Figure 1-5 , a connection structure between an aluminum frame of a semi-trailer and a steel traction plate 5, comprising: a girder 1, a front end beam 2, a traction plate transverse beam 6, a traction plate longitudinal beam 7, a traction pin 8 and a traction plate 5.

[0033] The front end beam 2 is welded to the front end of the girder 1, both the girder 1 and the front end beam 2 are made of aluminum profile, the front end beam 2 is made of a rectangular tube of aluminum profile, and the girder 1 is made of an I-shaped aluminum beam.

[0034] The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com