A kind of preparation method of cefoxizone sodium

A technology of cefozione sodium and cefoxime acid, which is applied in the field of medicine, can solve the problems of large pollution, low drying efficiency, and easy residue, and achieve the effects of reducing production costs, shortening the production cycle, and reducing solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

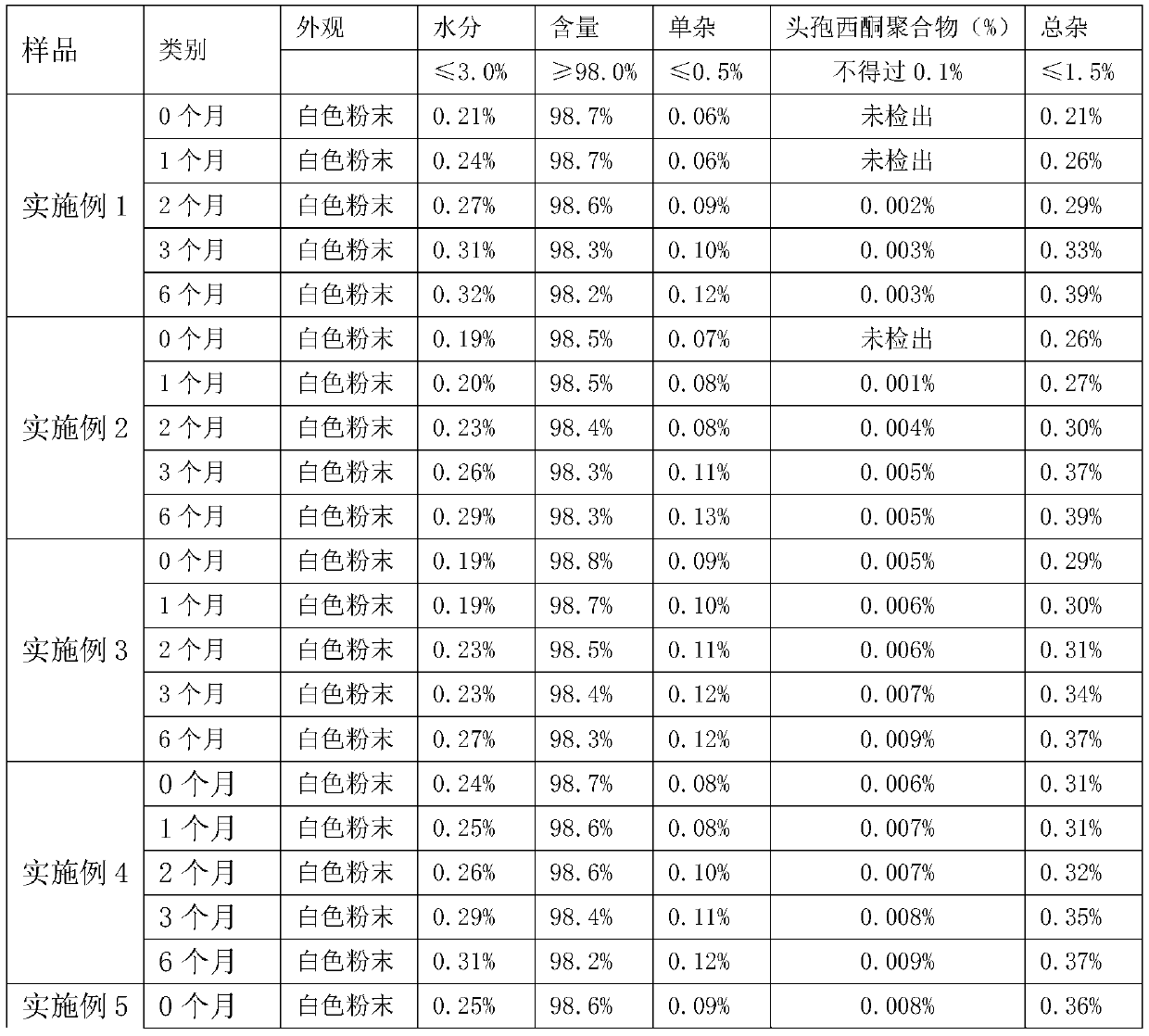

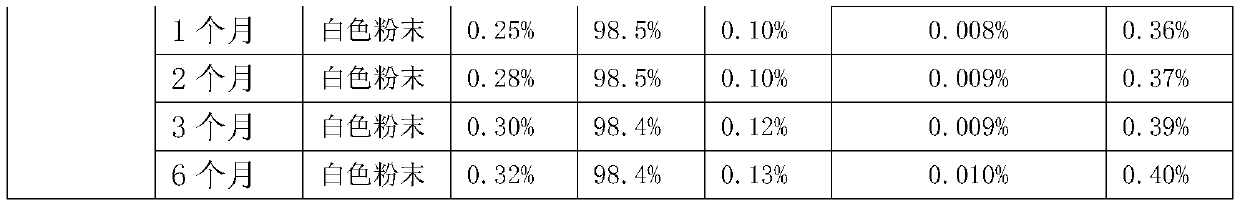

Embodiment 1

[0034] (1) Add 27.42 g of cefoxime acid to 192 mL of a mixed solvent of methanol and isopropanol (methanol: isopropanol = 1:3 (v / v)), lower the temperature to 8°C, and stir (45HZ) for 5 minutes under temperature control , slowly add methanol / triethylamine (methanol:triethylamine=2:1 (v / v)) mixed solution 23ml, control the addition time for 30min;

[0035] (2) Add 1.35g of activated carbon and stir (45HZ) for 15min, filter and enter the crystallization tank;

[0036] (3) Control the temperature of the reaction solution at 8°C, add acetic acid to adjust the pH value to 5 within 30min, add 1.64g of sodium acetate, after the addition is complete, stir (45HZ) for 30min, cool down to 3°C, add 0.10g of seed crystals, and keep stirring ( 45HZ) 30min;

[0037] (4) Add 3.69g of sodium acetate within 1 hour, keep warm at 3°C to grow crystals for 1.5 hours, add 411.3ml of acetone within 30 minutes, after adding, keep stirring (45HZ) for 2 hours;

[0038] (5) Blowing, vacuum drying, he...

Embodiment 2

[0040] (1) Add 27.42 g of cefoxime acid to 165 ml of a mixed solvent of methanol and isopropanol (methanol: isopropanol = 1:2 (v / v)), lower the temperature to 10°C, and stir under temperature control (45HZ) for 7 minutes , slowly add methanol / triethylamine (methanol:triethylamine=2.5:1 (v / v)) mixed solution 14ml, control the addition time for 20min;

[0041] (2) Add 1.35g of activated carbon and stir (45HZ) for 10min, filter and enter the crystallization tank;

[0042] (3) Control the temperature of the reaction solution at 10°C, add acetic acid to adjust the pH value to 4 within 25min, add 1.23g of sodium acetate, after the addition is complete, stir (45HZ) for 35min, cool down to 3°C, add 0.10g of seed crystals, and keep stirring ( 45HZ) 35min;

[0043] (4) Add 3.28g of sodium acetate within 1h, keep warm at 3°C for 2h, add acetone 274.2ml within 25min, keep stirring (45HZ) for 2.5h;

[0044] (5) Blowing, vacuum drying and heating program: Room temperature rises to 40°C,...

Embodiment 3

[0046] (1) Add 27.42 g of cefoxime acid to 220 ml of a mixed solvent of methanol and isopropanol (methanol: isopropanol = 1:4 (v / v)), cool down to 7°C, stir for 4 minutes under temperature control, and slowly add Methanol / triethylamine (methanol:triethylamine=1.5:1 (v / v)) mixed solution 33ml, control the addition time 40min;

[0047] (2) Add 1.35 g of activated carbon and stir for 20 minutes, filter and enter the crystallization tank;

[0048] (3) Control the temperature of the reaction solution at 7°C, add acetic acid to adjust the pH value to 6 within 35min, add 2.05g of sodium acetate, after the addition is complete, stir (45HZ) for 25min, cool down to 3°C, add 0.10g of seed crystals, and keep stirring ( 45HZ) 25min;

[0049] (4) Add 4.1 g of sodium acetate within 1.5 hours, keep the crystal at 3°C for 1 hour, add 548.4 ml of acetone within 35 minutes, and keep stirring for 1.5 hours;

[0050] (5) Blowing, vacuum drying temperature rise program is room temperature rises t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com