Airgel modified two-component waterborne polyurethane elastic runway coating and its preparation and application method

A water-based polyurethane, two-component technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as decreased elasticity, limited elasticity, and hidden dangers of runway health, and achieve the effect of delaying aging and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

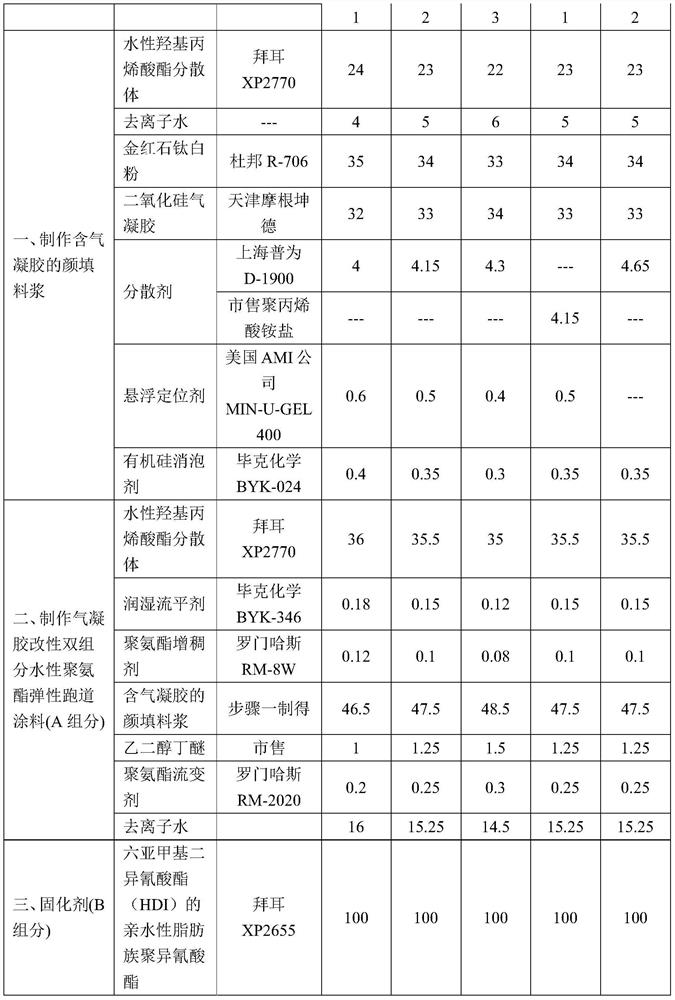

Embodiment 1

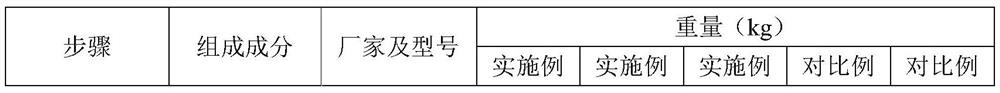

[0057] Step 1. Prepare pigment paste:

[0058] Add 24kg of water-based hydroxyl functional polyacrylate dispersion into the pre-dispersion tank, start stirring, then add 4kg of deionized water, 35kg of rutile titanium dioxide, and 32kg of nano-silica airgel in turn under stirring, and then turn on the water at 1000 rpm Pre-disperse for 15 minutes at a speed of 1 / min; then add 4kg of A-B block polymer hyperdispersant, 0.6kg of magnesium aluminum silicate suspending agent, and 0.4kg of silicone defoamer in sequence under stirring, and increase the speed to Stir and disperse at high speed at 1500 rpm for 30 minutes, then grind for 4 to 5 hours with a pin-type sand mill, and set aside.

[0059] Step 2. Prepare component A:

[0060] Weigh and add 36kg of water-based hydroxyl functional polyacrylate dispersion in the production tank, then add 0.18kg of wetting and leveling agent and 0.12kg of polyurethane thickener successively under stirring at 500 rpm. Stir at different speeds f...

Embodiment 2

[0067] Step 1. Prepare pigment paste:

[0068] Add 23kg of water-based hydroxyl functional polyacrylate dispersion into the pre-dispersion cylinder, start stirring, then add 5kg of deionized water, 34kg of rutile titanium dioxide, and 33kg of nano-silica airgel in turn under stirring. Pre-disperse for 15 minutes at the rotating speed per minute; then add 4.15kg of A-B block polymer hyperdispersant, 0.5kg of magnesium aluminum silicate suspending agent, and 0.35kg of silicone defoamer in sequence under stirring, and increase the rotating speed after adding Stir and disperse at a high speed at 1500 rpm for 30 minutes, then grind for 4 to 5 hours with a pin-type sand mill, and set aside.

[0069] Step 2. Prepare component A:

[0070] Weigh and add 35.5kg of water-based hydroxy-functional polyacrylate dispersion into the production tank, then add 0.15kg of wetting and leveling agent and 0.1kg of polyurethane thickener in sequence under stirring at 500 rpm, and then add it at 500 ...

Embodiment 3

[0077] Step 1. Prepare pigment paste:

[0078] Add 22kg of water-based hydroxyl functional polyacrylate dispersion into the pre-dispersion cylinder, start stirring, and then add 6kg of deionized water, 33kg of rutile titanium dioxide, and 34kg of nano-silica airgel in turn under stirring. Pre-disperse for 15 minutes at the rotating speed per minute; then add 4.3kg of A-B block polymer hyperdispersant, 0.4kg of magnesium aluminum silicate suspending agent, and 0.3kg of organosilicon defoamer in sequence under stirring, and increase the rotating speed after adding Stir and disperse at a high speed at 1500 rpm for 30 minutes, then grind for 4 to 5 hours with a pin-type sand mill, and set aside.

[0079] Step 2. Prepare component A:

[0080]Weigh and add 35kg of water-based hydroxyl functional polyacrylate dispersion in the production tank, then add 0.12kg of wetting and leveling agent and 0.08kg of polyurethane thickener under stirring at 500 rpm, and then add it at 500 rpm Sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com