Assembled building component joint seam bin separation construction tool and method

A technology of building components and construction tools, which is applied in building components, building structures, buildings, etc., can solve the problems of poor quality of warehouse division, and achieve the effects of convenient size and close room, flexible warehouse division time, and avoiding process confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

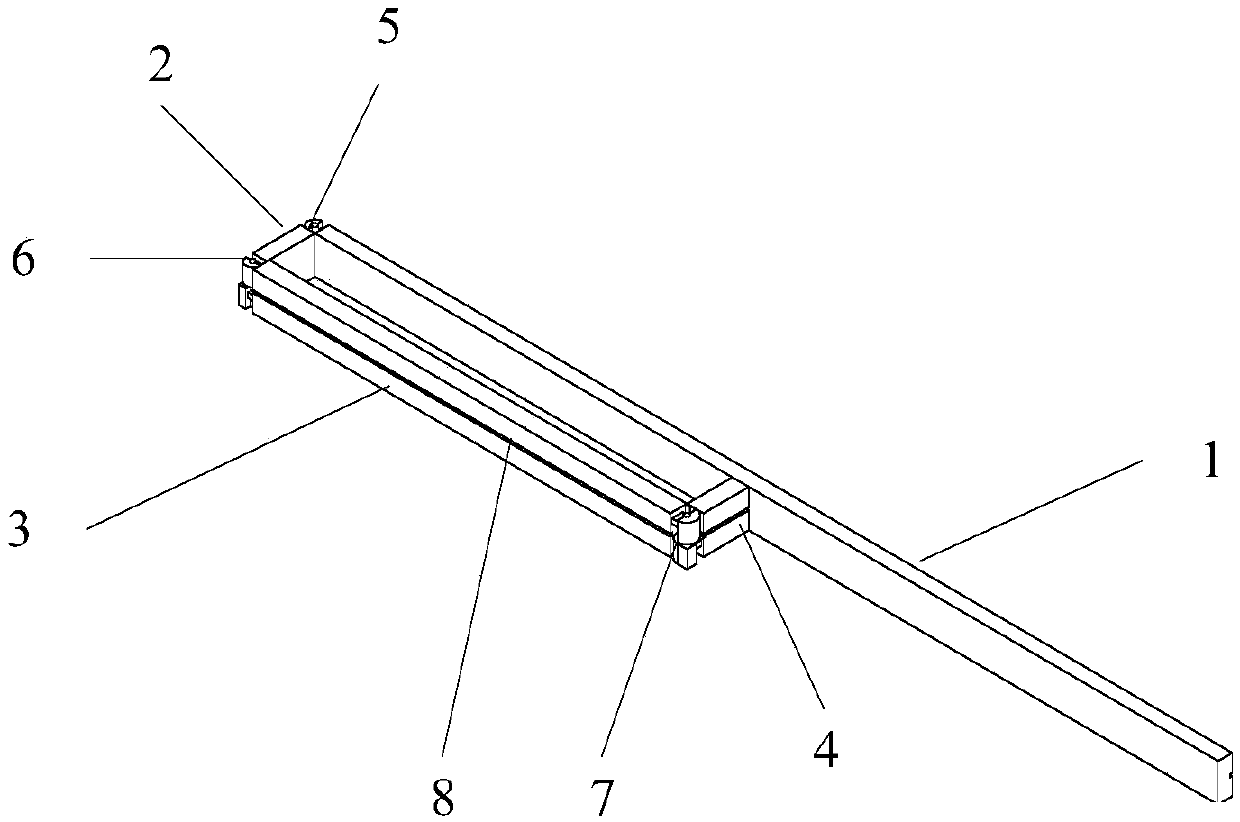

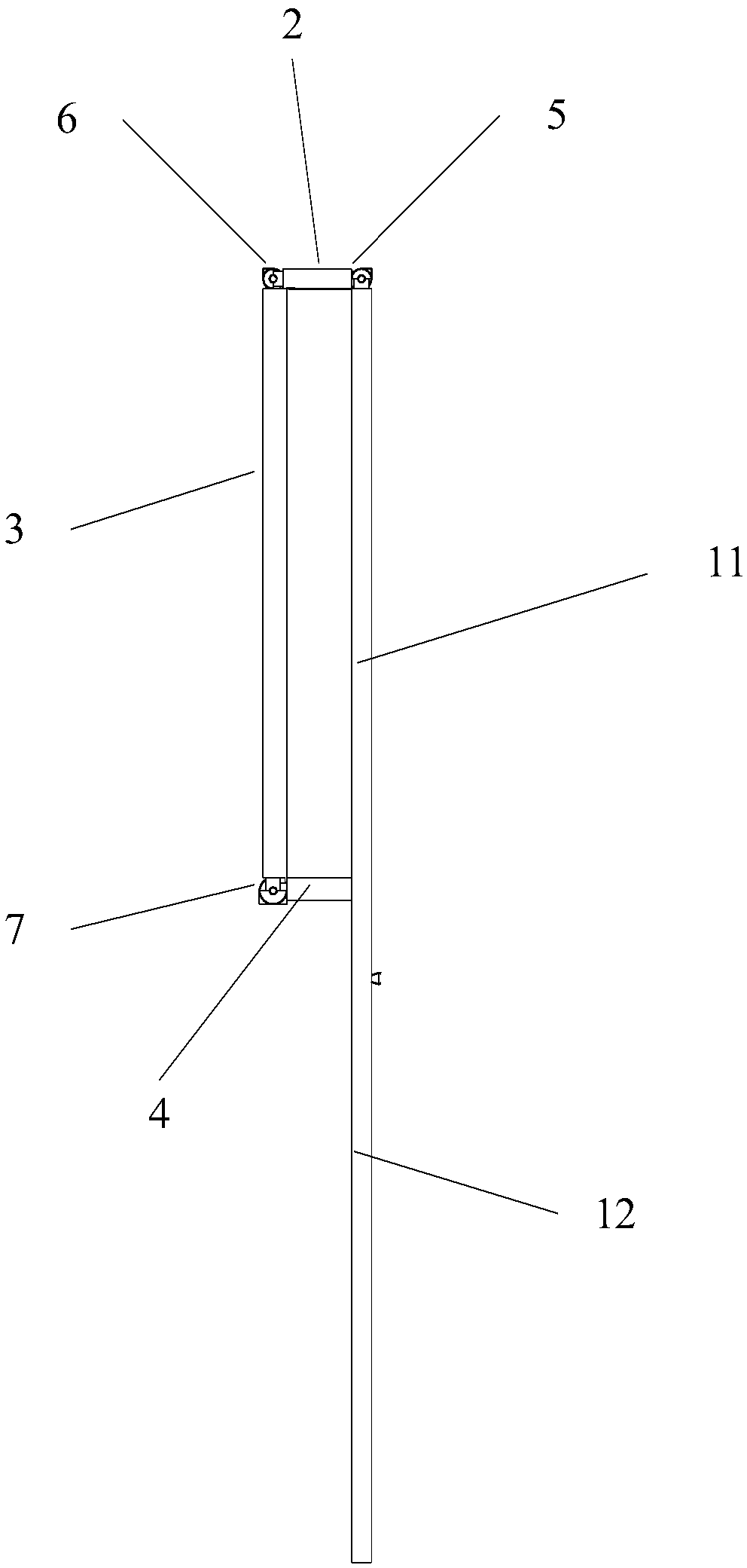

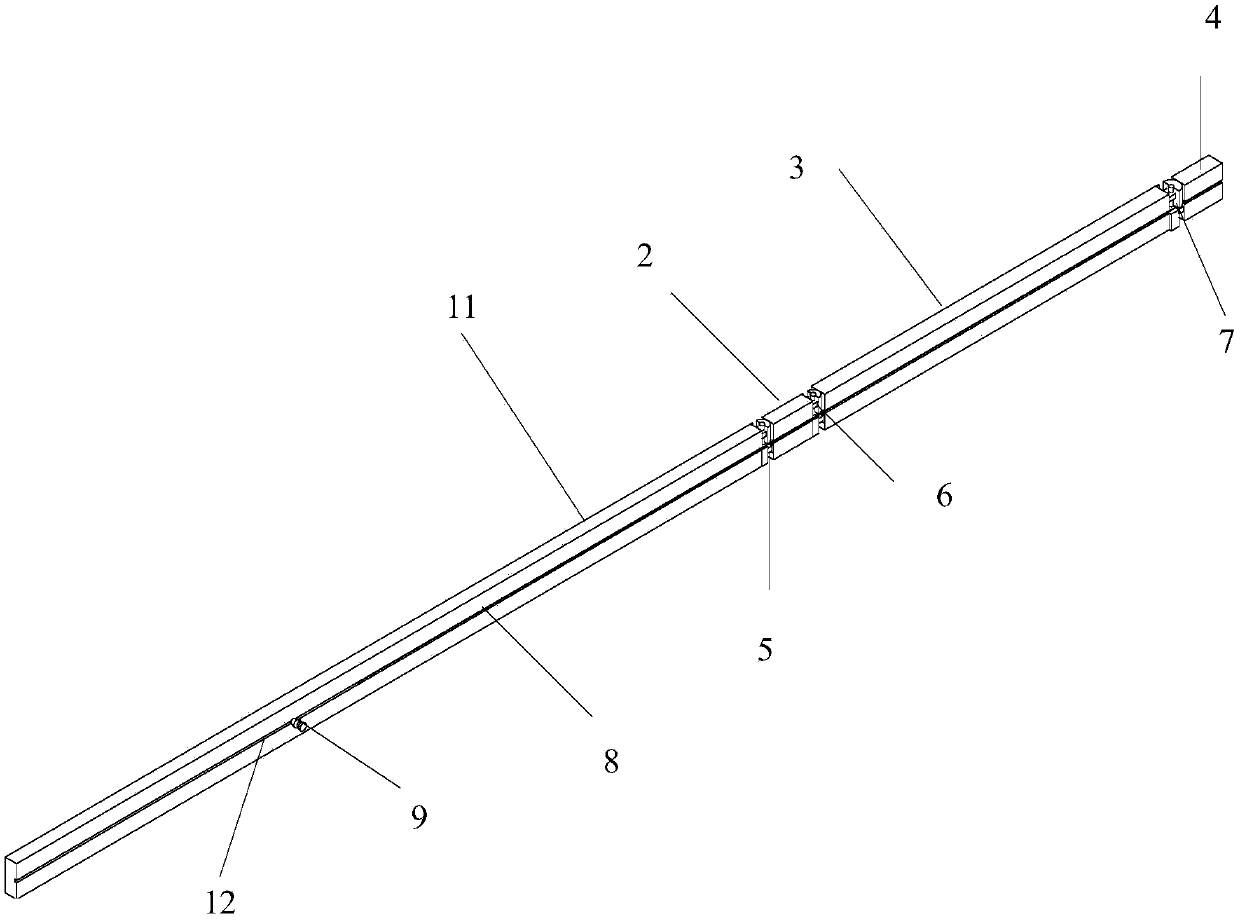

[0027] Such as Figure 1~3 As shown, the present invention provides a construction tool for prefabricated building components, which includes four sections of connecting rods, namely the first connecting rod 1, the second connecting rod 2, the third connecting rod 3 and the fourth connecting rod 4 ,in,

[0028] The first connecting rod 1 includes a jointed bin section 11 and a handle section 12 connected together, one end of the stitched bin section 11 is connected to one end of the handle section 12, and the stitched bin section The other end of the segment 11 is connected to one end of the second connecting rod 2 through the first rotating shaft 5 with a preset angle limit;

[0029] The other end of the second connecting rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com