A construction method for waterproofing and plugging in building areas

A technology of building areas and construction methods, applied in construction, building maintenance, building construction, etc., can solve problems affecting the appearance of decoration materials, damage to decoration materials, etc., and achieve the goal of reducing construction time, saving economic resources, and simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

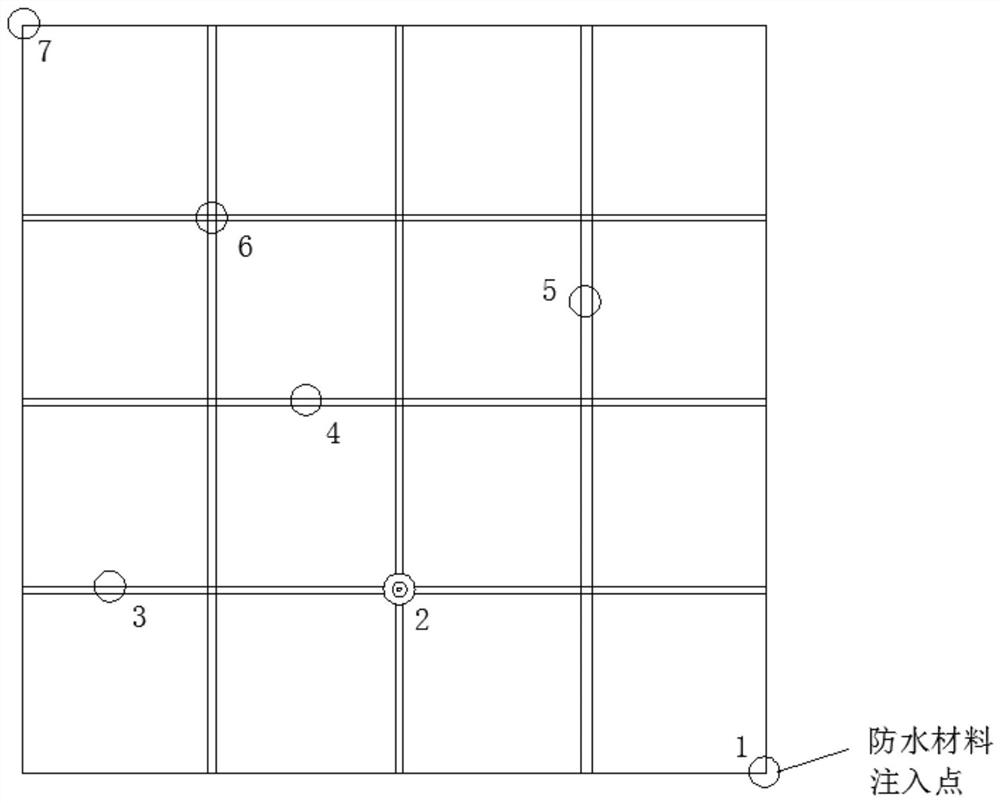

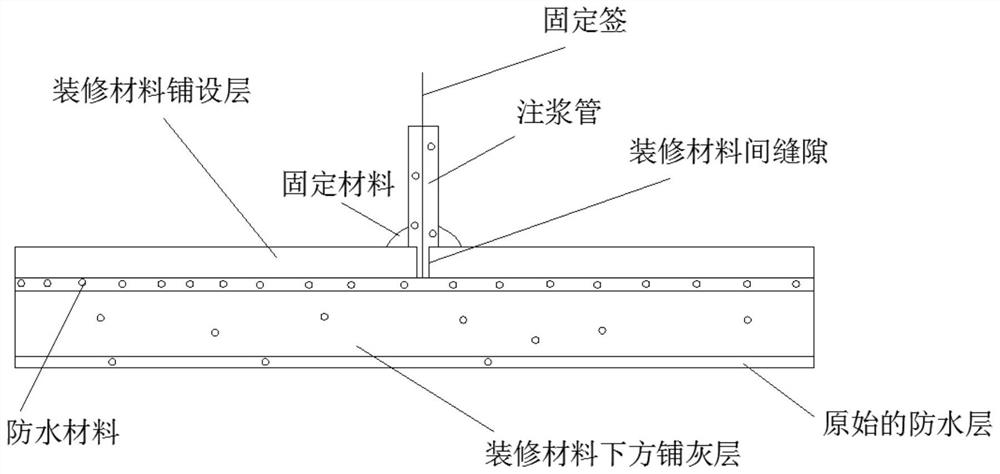

[0047] A waterproof plugging construction method in a construction area, the construction area to be constructed in embodiment 1 is a toilet floor with ceramic tiles, and there is an original waterproof layer under the gray layer for laying ceramic tiles, such as Figure 1-3 shown, including the following steps:

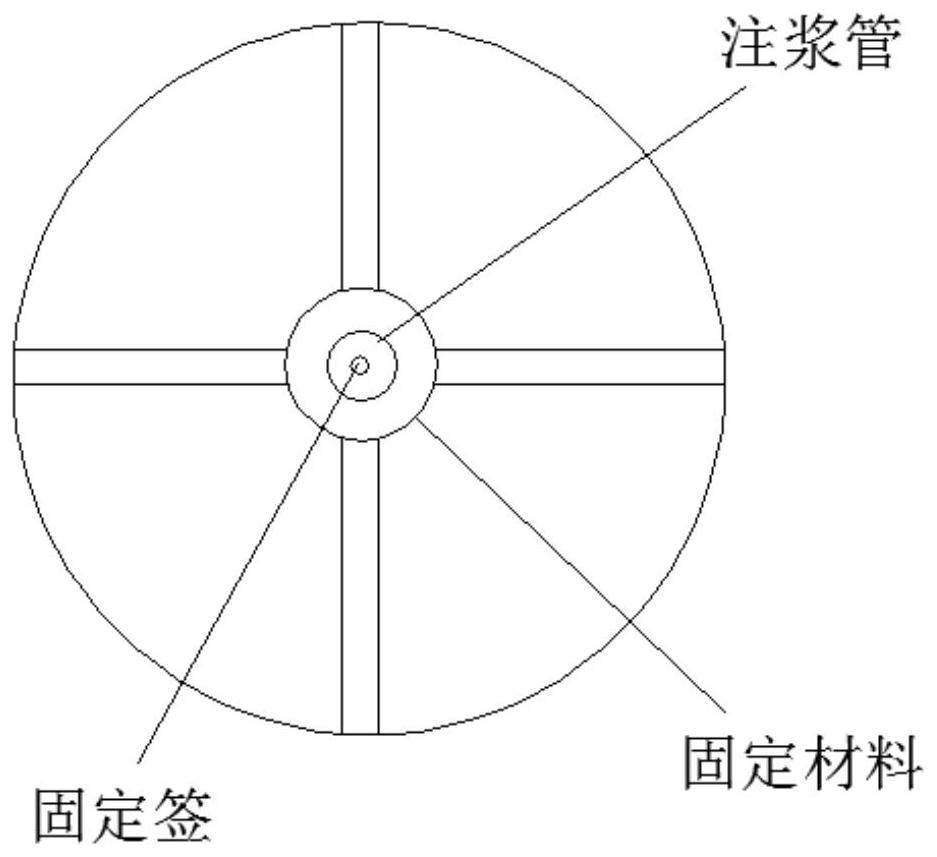

[0048] S1. Randomly select 7 injection points of waterproof materials in the gaps where the tiles of decoration materials are laid on the bathroom floor of the building area to be constructed, and insert fixed signs into the gaps of the injection points of waterproof materials. " and linear gaps, the thickness of the fixed sign is less than the width of the gap between the decoration materials; the thickness of the fixed sign is 1.5mm, the height is 20cm, the width of the gap between the decoration materials is 2mm, and the gap is filled with gray layer materials for laying tiles; the fixed sign It only needs to be embedded in the gap between the decoration materials...

Embodiment 2

[0055] A waterproof plugging construction method in a construction area, which is basically the same as the method in Embodiment 1, the difference is that the construction area to be constructed is a wall, and the decoration material of the wall is marble; the insertion point of the fixed sign is the gap between the decoration materials The gap between the decoration materials is 1mm, the thickness of the fixing stick is 0.5mm; the length of the grouting pipe is 20cm, the inner diameter of the pipe is 5mm, and the outer diameter of the grouting pipe is larger than the width of the gap between the decoration materials .

[0056] The solidification time of the fixing material in Example 2 is 20 minutes, and the gelation time of the acrylate grouting material is about 5 minutes. The whole waterproof plugging process takes 1 hour in total, and the water avoidance test can be done immediately after the end; Inserting the water stop needle does not need to damage the marble surface....

Embodiment 3

[0058] A waterproof plugging construction method in a building area, the building area to be constructed in embodiment 3 is a bay window, and the window frame of the bay window and the wall are "point-type" bonded and fixed by an adhesive material, such as Figure 4 As shown, there are still many gaps between the window frame of the bay window and the wall, and there is no original waterproof layer.

[0059] The construction method of embodiment 3 is basically the same as that of embodiment 1, the difference is that the grouting pipes are distributed circularly in the building area to be constructed; the insertion point of the fixed sign is any position where the window frame and the wall meet, and the The insertion position of the bottom end of the sign is the gap between the window frame and the wall; the gap between the window frame and the wall is 3mm, and the thickness of the fixed sign is 1mm; the length of the grouting pipe is 20cm, the inner diameter of the pipe is 5mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com