Stable support device of vertical shaft heading machine

A technology for stabilizing supports and supporting devices, which can be used in temporary shields, mining equipment, earthwork drilling and mining, etc., and can solve problems such as vibration and affecting the stability of the formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

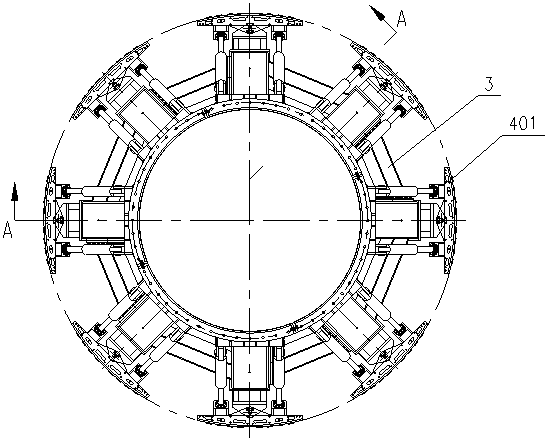

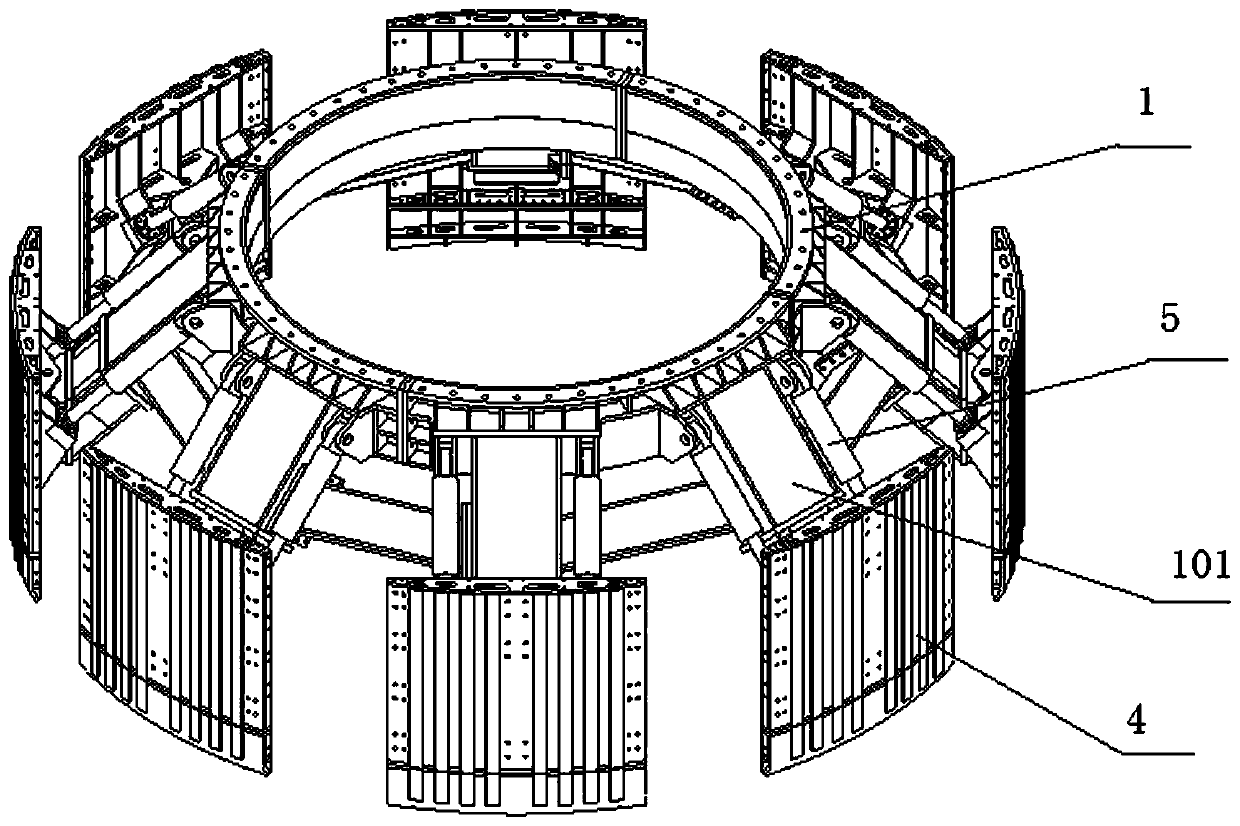

[0023] Embodiment 1: as figure 1 and Figure 4 As shown, a stable support device for a shaft boring machine, the stable support device is installed around the main drive 6 above the cutter head, and the cutter head 7 will inevitably vibrate during the rock excavation process under the action of the main drive, the stable support device is In order to stabilize the cutterhead 7, reduce the impact of equipment vibration on the stratum, improve the safety of the roadheader during the excavation process and the service life of the equipment, a fixed center ring 1 is arranged around the main drive above the roadheader cutterhead, and the fixed center ring 1 There are several telescopic devices on the upper outer ring, and eight sets of telescopic devices are arranged on the upper ring of the fixed center ring. The adjacent telescopic devices are connected by connecting devices. The device is provided with a supporting device, and the telescopic device is connected with the support...

Embodiment 2

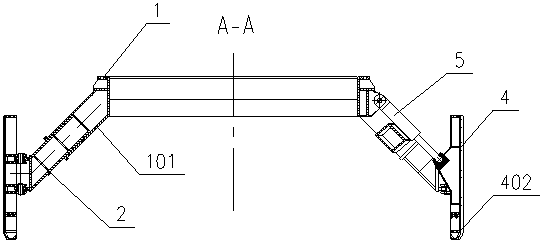

[0027] Embodiment 2: as figure 2 As shown, a stable support device for a shaft boring machine, the main panel is provided with a wear-resistant metal strip 401 and a cutting edge guide block 402, and the wear-resistant metal strip 401 is vertically spaced apart, which is beneficial to resist the backlash of the equipment. Torque, the lower part of the main panel is provided with an edge guide plate 402, the edge guide plate 402 is a guide plate with a tip, the edge guide block 402 is detachably connected with the main panel, and the edge guide block 402 is connected to the main panel through high-strength bolts In connection with each other, wear-resistant metal strips 401 are used to increase the friction between the sliding shield 4 and the formation to improve the stability of the support device, and using the edge guide block 402 is more conducive to the sliding shield 4 moving downward along the well wall.

[0028] All the other structures are the same as in Example 1. ...

Embodiment 3

[0029] Example 3, such as figure 1 As shown, a stable support device for a shaft boring machine, the fixed central ring 1 includes several block structures, the fixed central ring 1 is composed of 4 block structures, and the block structures adopt steel structures, and each block structure passes through Bolts are connected, two sets of tensioning cylinders 5 and a set of telescopic sliding boxes 2 are fixed on each block structure, and the two sets of tensioning cylinders 5 and one set of telescopic sliding boxes 2 are connected with a set of sliding shields The inter-connection is convenient, and it is convenient to disassemble the machine underground.

[0030] All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com