Patents

Literature

61results about How to "Act as a temporary support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

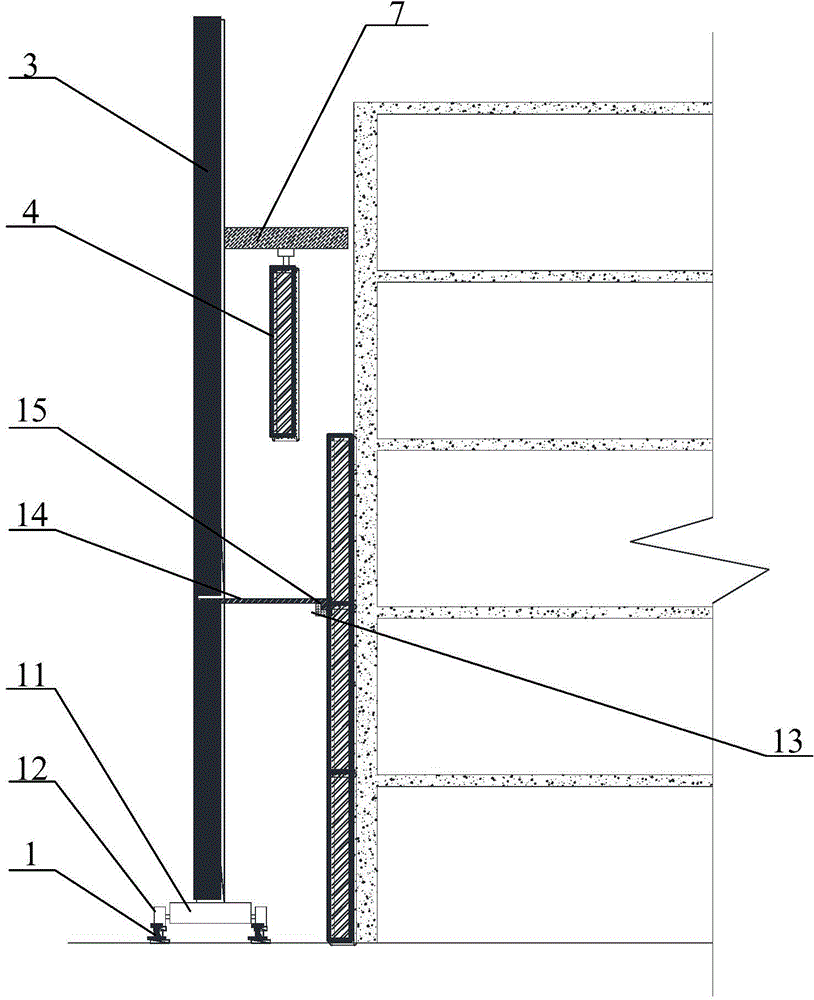

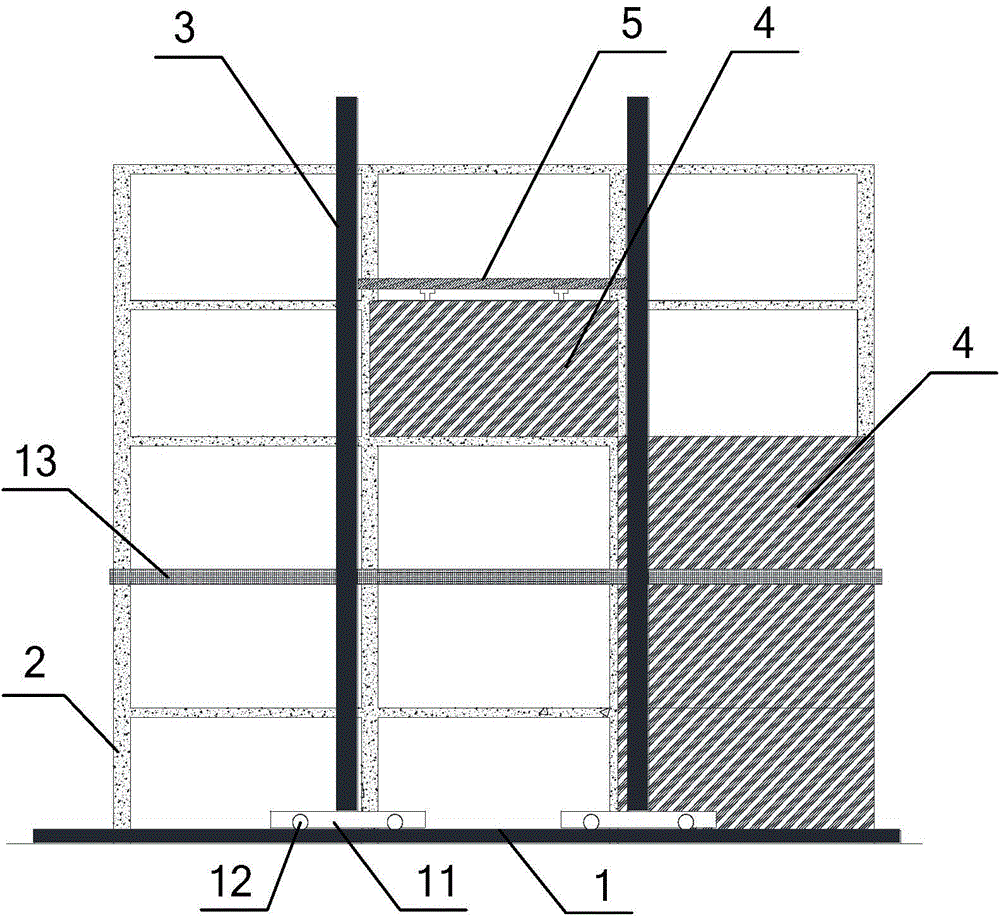

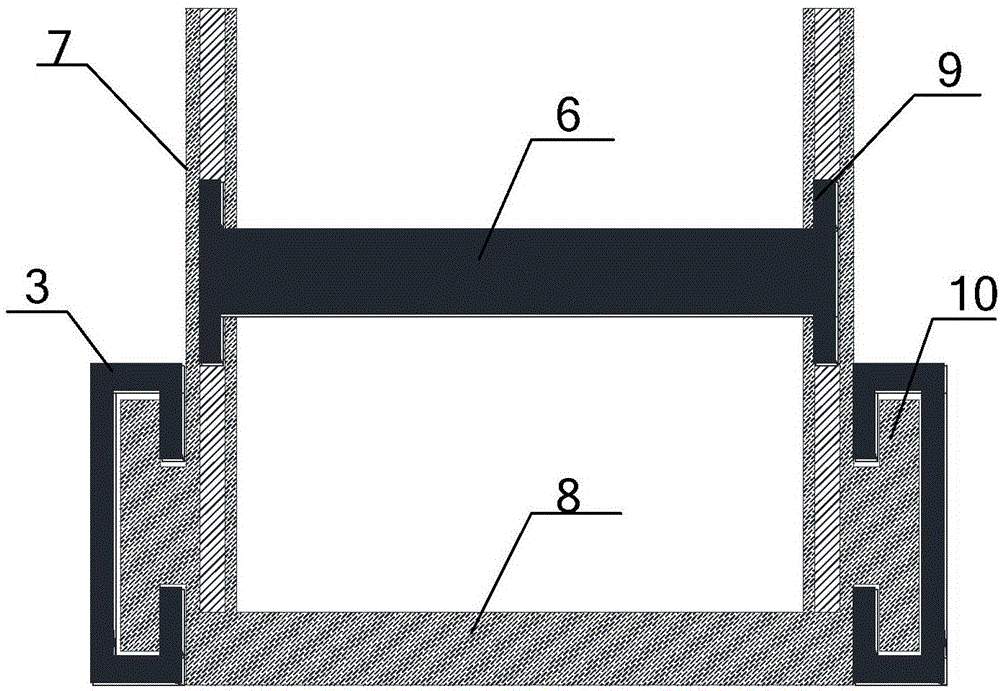

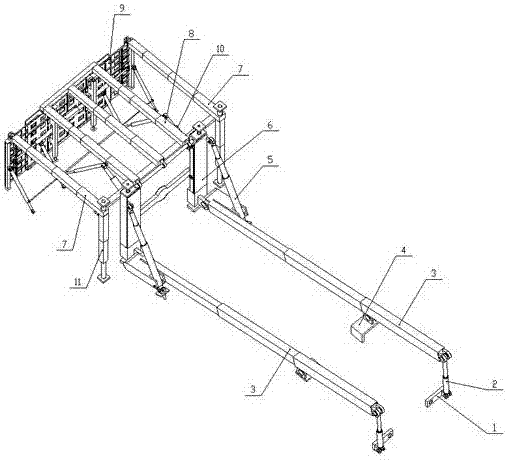

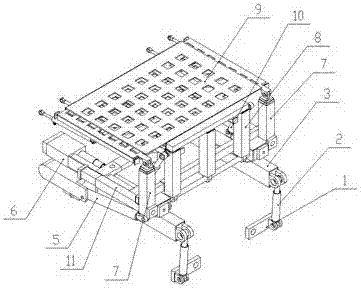

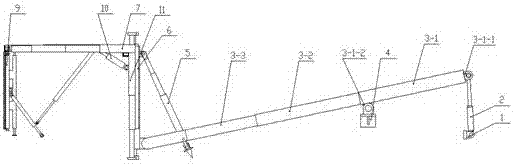

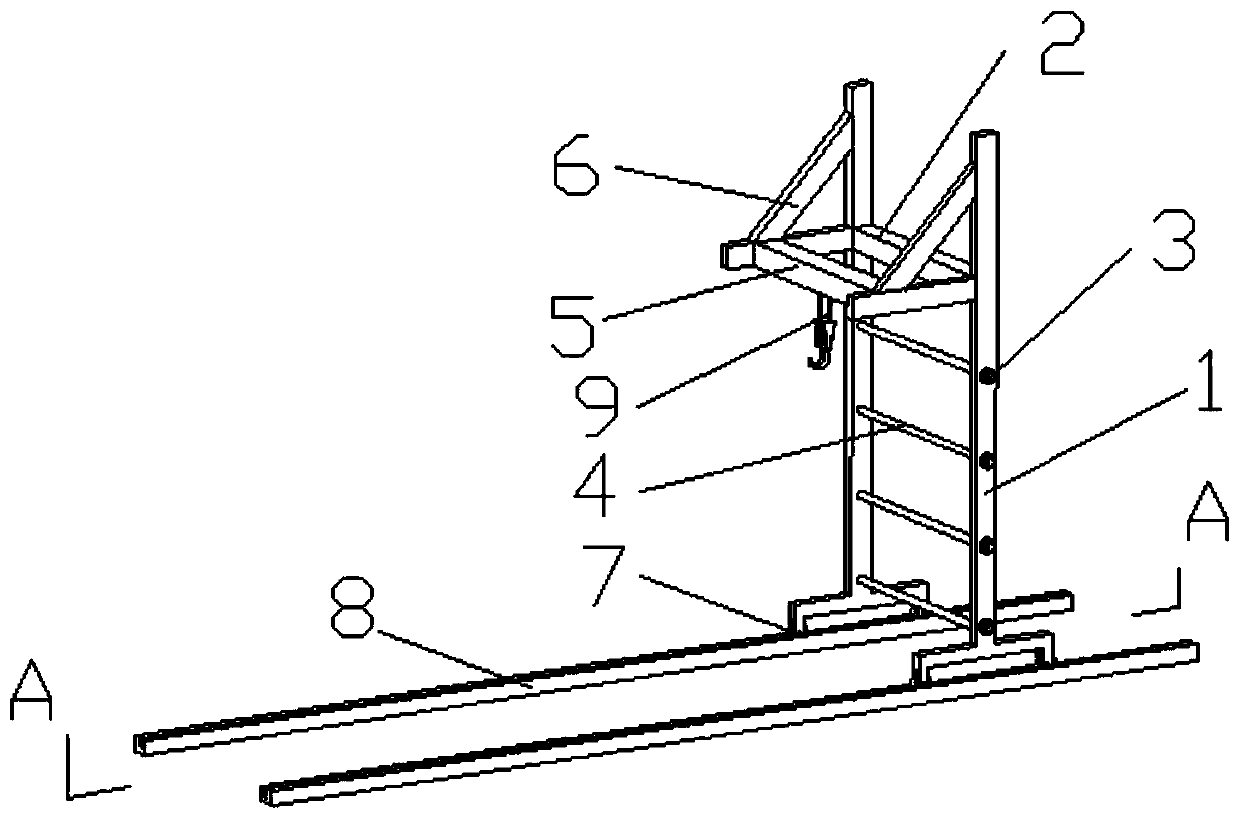

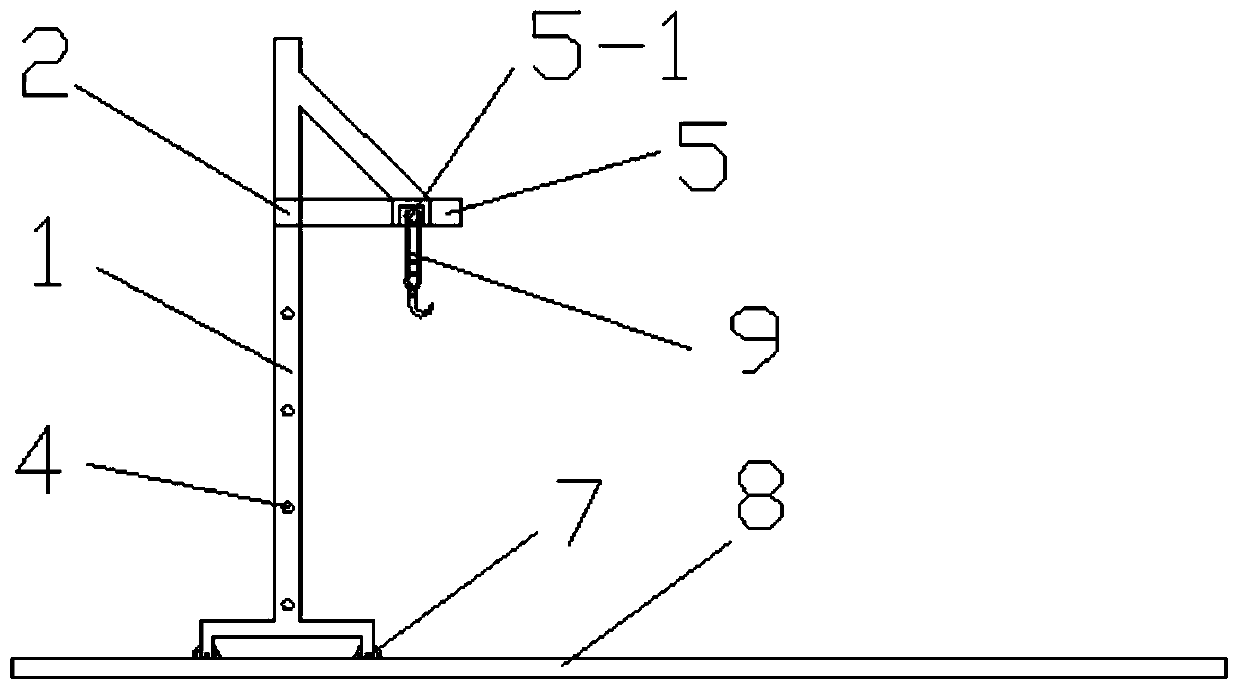

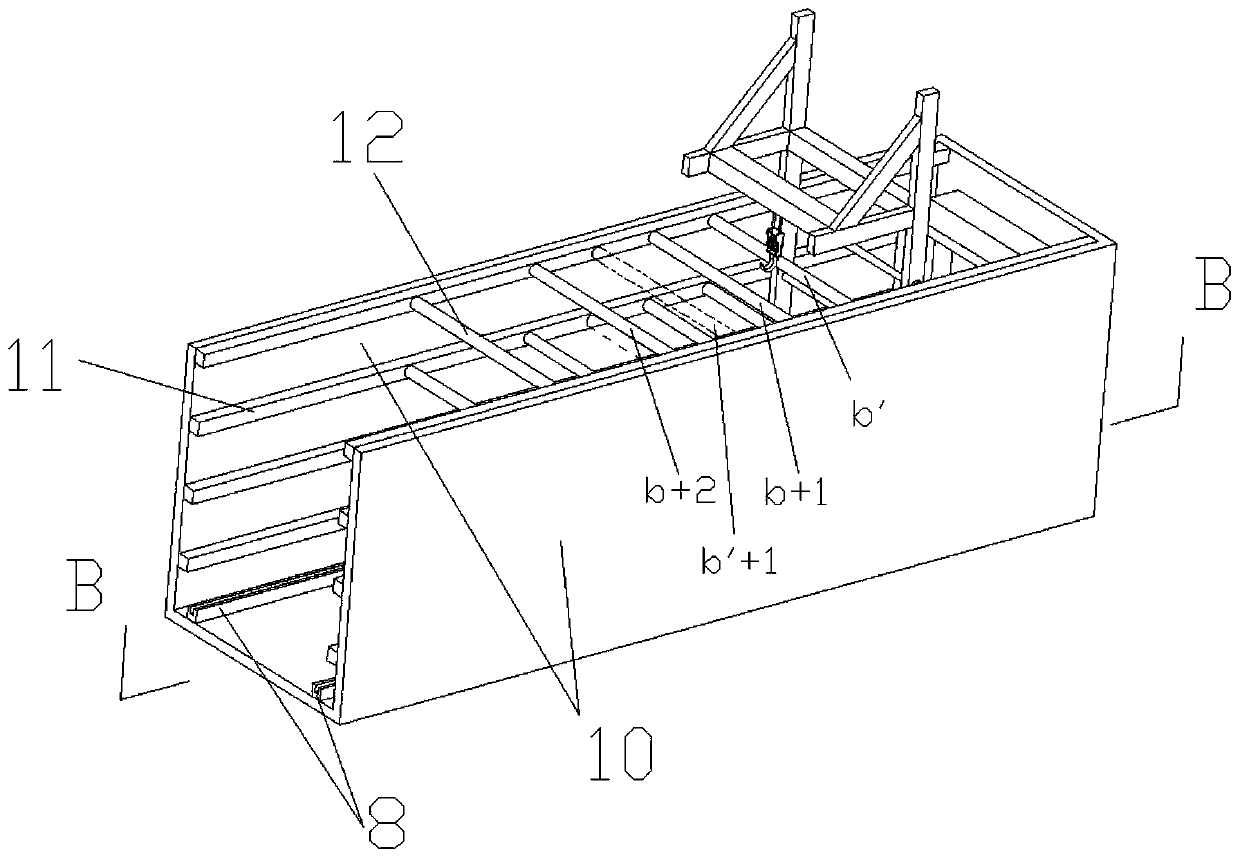

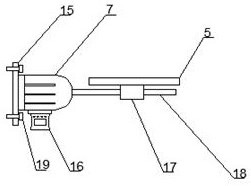

Rapid in-place device and rapid in-place method for prefabricated wallboard of prefabricated building

ActiveCN104563528AImprove efficiencyHigh precisionBuilding material handlingAgricultural engineeringEngineering

Owner:SHANGHAI CONSTRUCTION GROUP

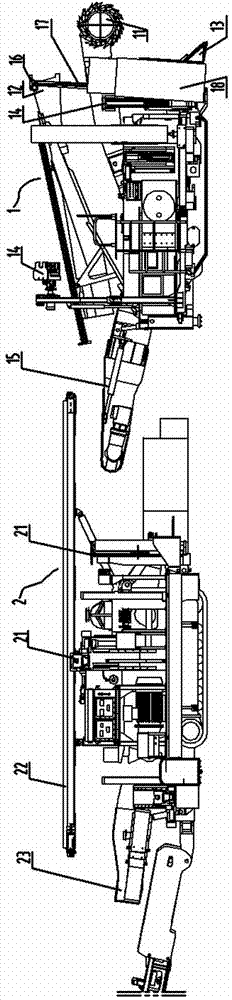

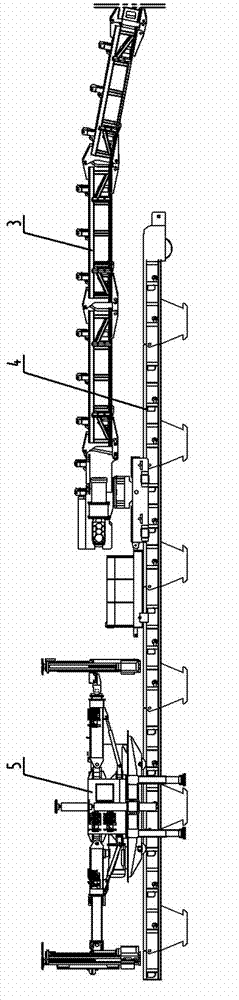

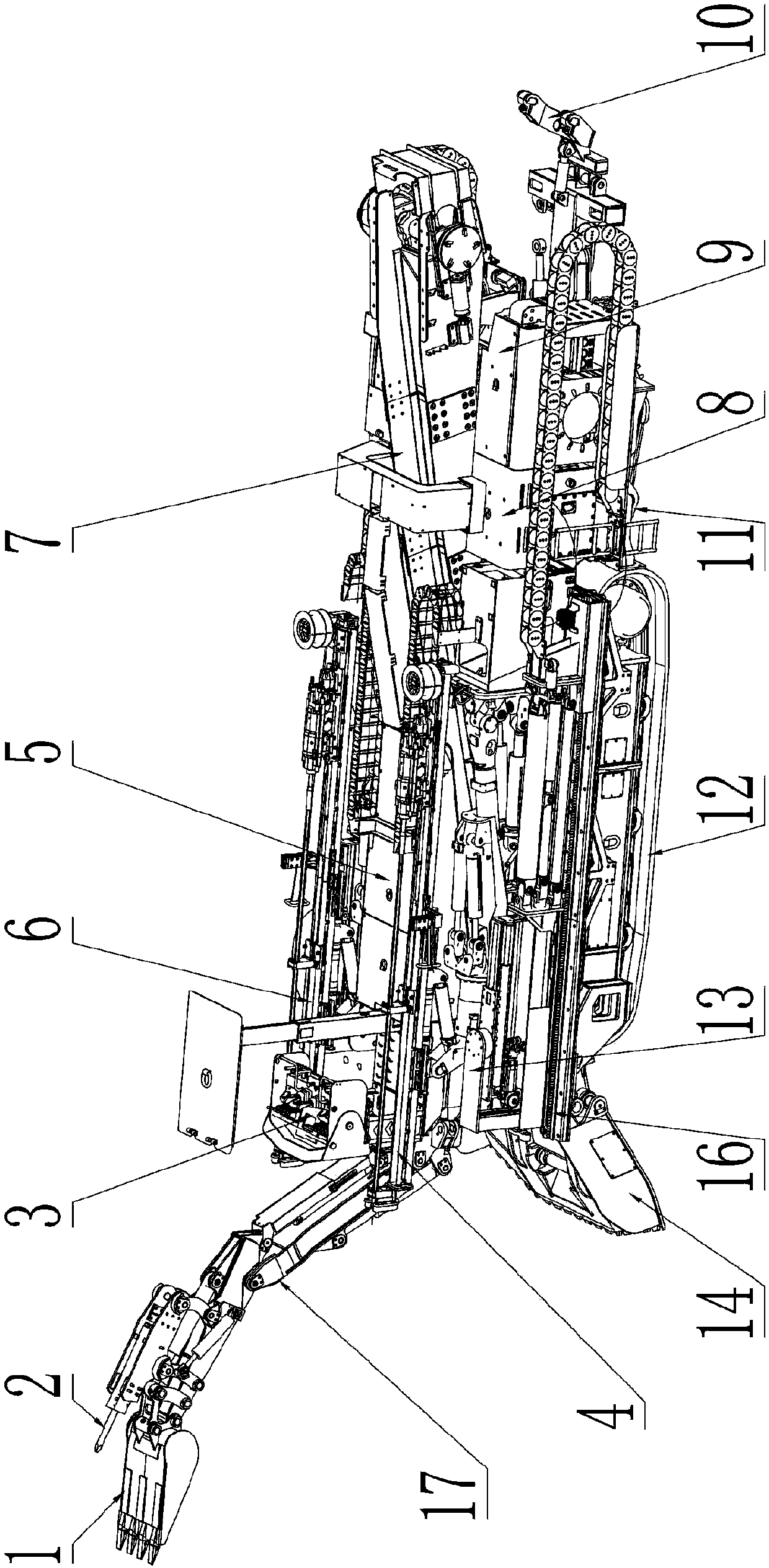

Rapid drivage-anchoring integrated equipment for coal road under instable surrounding rock condition

ActiveCN104747201AImprove efficiencyAvoid destructionTunnelsAnchoring boltsRubber sheetDrilling machines

The invention discloses rapid drivage-anchoring integrated equipment for a coal road under an instable surrounding rock condition. The equipment comprises a drivage-anchoring machine and an anchor rod drill carriage, the drivage-anchoring machine comprises a cutting roller, an air draft pipeline, a material collector, an anchor rod drilling machine set and a scraper conveyor, the anchor rod drill carriage comprises an anchor rod drill drilling machine set and a scraper conveyor, the anchor rod drill carriage is arranged behind the drivage-anchoring machine, the rear portion of the scraper conveyor of the drivage-anchoring machine is located over the front portion of the scraper conveyor of the anchor rod drill carriage, a roof-caving-preventing device is arranged on the drivage-anchoring machine, a sealing device is connected below the roof-caving-preventing device, the sealing device is composed of a moving sealing rubber sheet, a fixed sealing rubber sheet, a telescopic oil cylinder, a cross beam and a telescopic beam, the cross beam is connected with one end of the telescopic oil cylinder, the other end of the telescopic oil cylinder is connected with the telescopic beam, the fixed sealing rubber sheet is connected below the cross beam, and the moving sealing rubber sheet is connected below the telescopic beam. By means of the equipment, the anchoring efficiency can be matched with the drivage efficiency, and the comprehensive drivage-anchoring efficiency is promoted.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

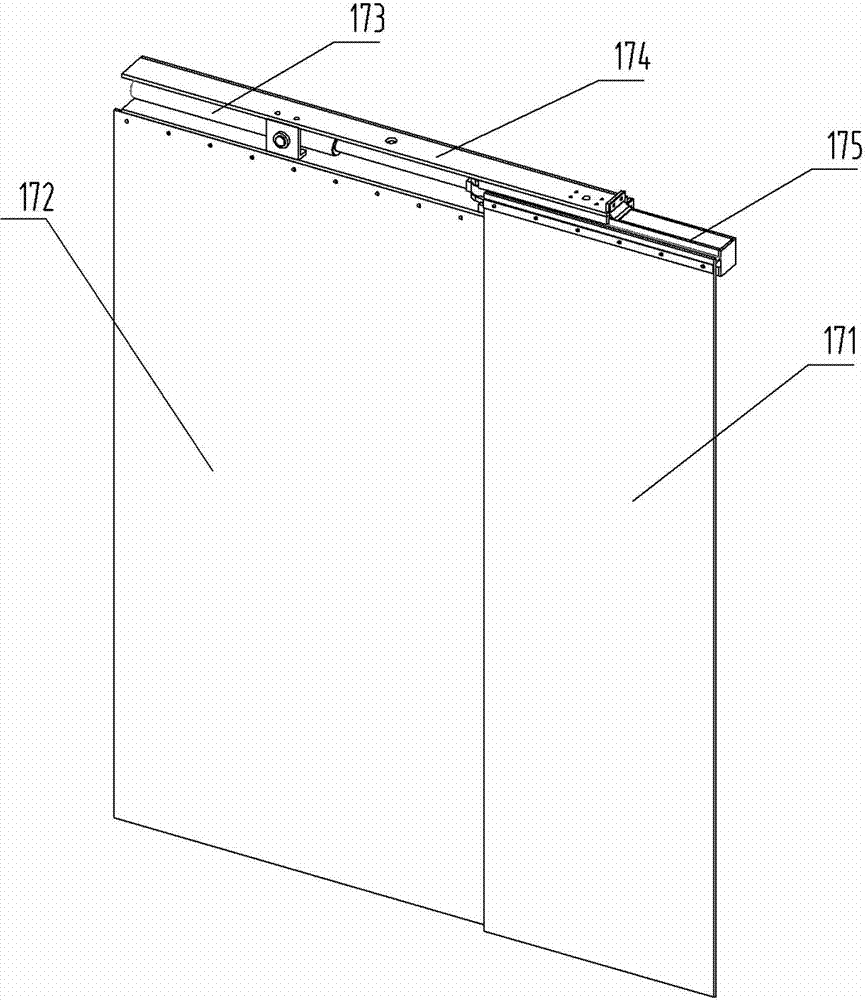

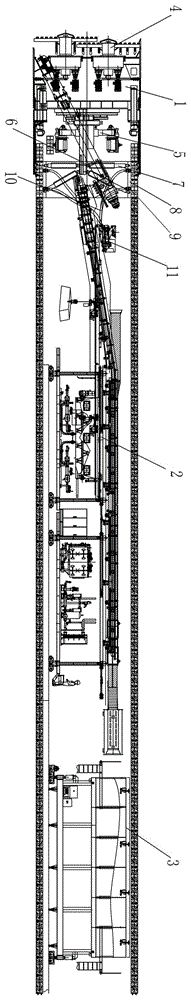

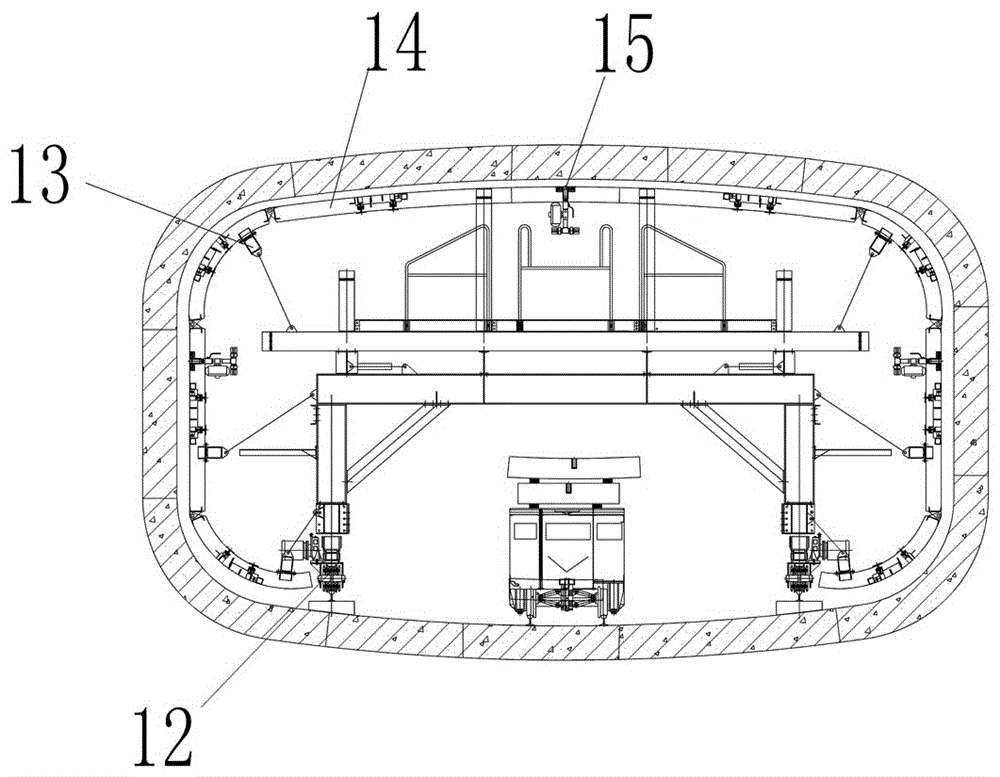

Device and method for constructing great depth rectangular or quasi-rectangular tunnel shield

ActiveCN106223967AIncrease profitImprove space utilizationUnderground chambersTunnel liningEconomic benefitsEngineering

The invention relates to the technical field of underground engineering construction, and particularly relates to a device and a method for constructing a great depth rectangular or quasi-rectangular tunnel shield, mainly aiming at providing the great depth rectangular or quasi-rectangular tunnel shield which is applicable to a great-depth assembled mechanical construction for improving the safety reliability in the constructing process and accelerating the construction progress. The device mainly comprises a shield host, a back auxiliary and a model board trolley, wherein a combined rotating cutter is arranged at the front end face of the shield host, and a rectangular segment erector is arranged at the rear end of the shield host; a model board telescopic cylinder is connected on a supporting cantilever at the rear end part of the rectangular segment erector, and a model board is connected with and fixed at the other end of the model board telescopic cylinder; a grouting opening is reserved in the model board; and the model board trolley is arranged at the rear end of the back auxiliary. The construction device and method have remarkable economic benefits in underground space utilization and material utilization.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

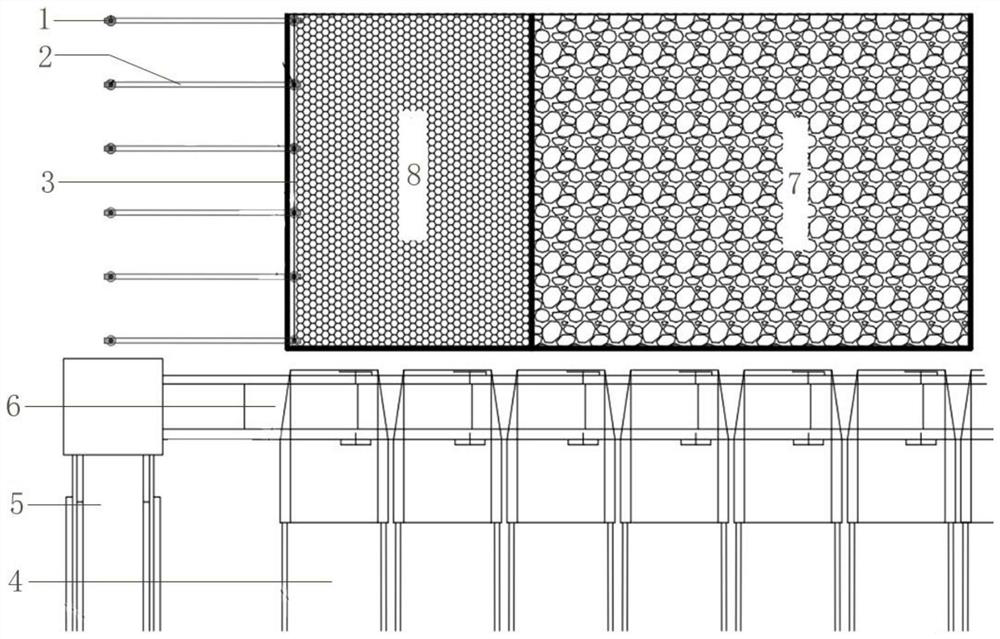

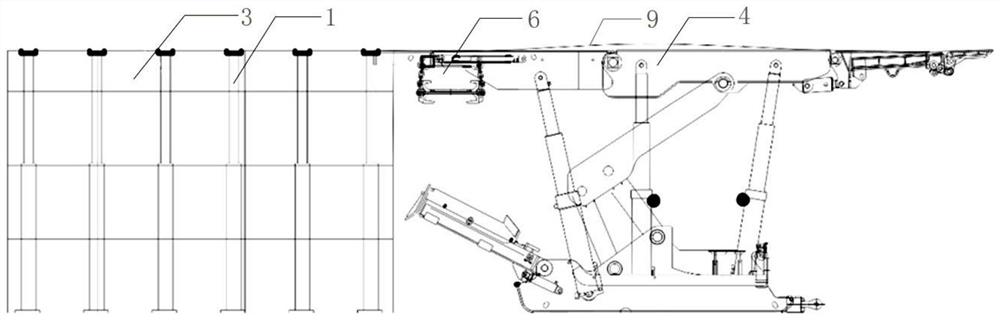

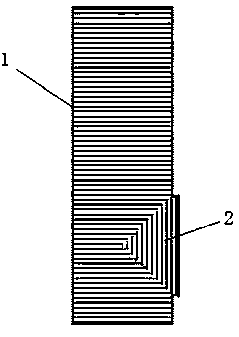

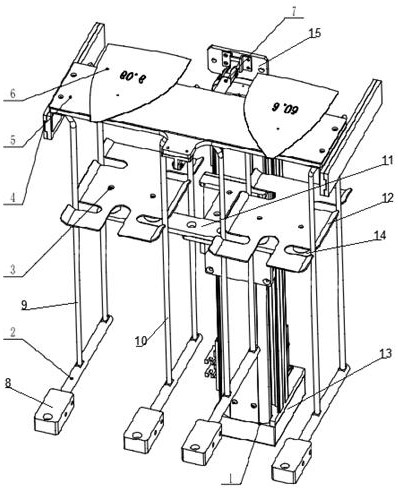

Advance timbering device of dig-anchor-integrated comprehensive mining machine

ActiveCN107060857ADo not block the line of sightCompact structureDerricks/mastsSlitting machinesMachineCantilever

An advance timbering device of a dig-anchor-integrated comprehensive mining machine is disclosed. The problems of low degree of automation and poor safety in the prior art are solved. The advance timbering device of the dig-anchor-integrated comprehensive mining machine is characterized in that a swing folding support is mounted at the front ends of telescopic beams, a combined type middle telescopic supporting beam and external telescopic supporting beams are mounted on the swing folding support, and a front combined baffle is hinged to the front ends of the combined type middle telescopic supporting beam and the external telescopic supporting beams. The advance timbering device has the beneficial effects that the structure is compact, the body is small, the advance timbering device can be folded through an overturning and folding machine frame and transferred to the rear portion of the machine body of the comprehensive mining machine through telescopic beams and a sliding transverse beam, work of a mining part of the comprehensive mining machine is not influenced, and influence on the other facilities at the rear portion of the machine body in a roadway is also slight; the combined front baffle can conduct supporting type protection on the front end surface of the roadway, and a relatively comprehensive and wide advance temporary supporting area is provided; five supporting beams provide strong support for the upper roof of the roadway, the problem of insufficiency of cantilever support capacity is solved radically, and a rapid and automatic advance timbering device is provided for roadway anchor protection.

Owner:沈阳重机重矿机械设备制造有限公司

Supporting device for tunnel construction

ActiveCN108729937AImprove securityImprove reliabilityMine roof capsProtective coversArchitectural engineeringTunnel construction

The invention relates to the technical field of tunnel construction, and discloses a supporting device for tunnel construction. The supporting device comprises two columns and two arching mechanisms.The tops of the two columns are respectively provided with a positioning groove, a positioning rod is fixedly connected to one side of each arching mechanism, and the positioning rods are located in the positioning grooves. One side of the bottom of each of the two arching mechanisms is fixedly connected with a supporting mechanism, and the bottom of the supporting mechanism is fixedly connected to the side of the corresponding column. The middles of the opposite sides of the two columns are both fixedly connected with a lapping block, one side of each lapping block away from the correspondingcolumn is provided with a lap groove, a cross bar is in lap joint between the two lap grooves, a reinforcing mechanism is fixedly connected to one side of the bottom of the cross bar, and the bottomof the reinforcing mechanism is fixedly connected to the sides of the columns. The supporting device is reasonable in design, high in practicability, convenient to install and remove and convenient topopularize and use. Construction workers can use the device conveniently.

Owner:杭州三阳建设集团有限公司

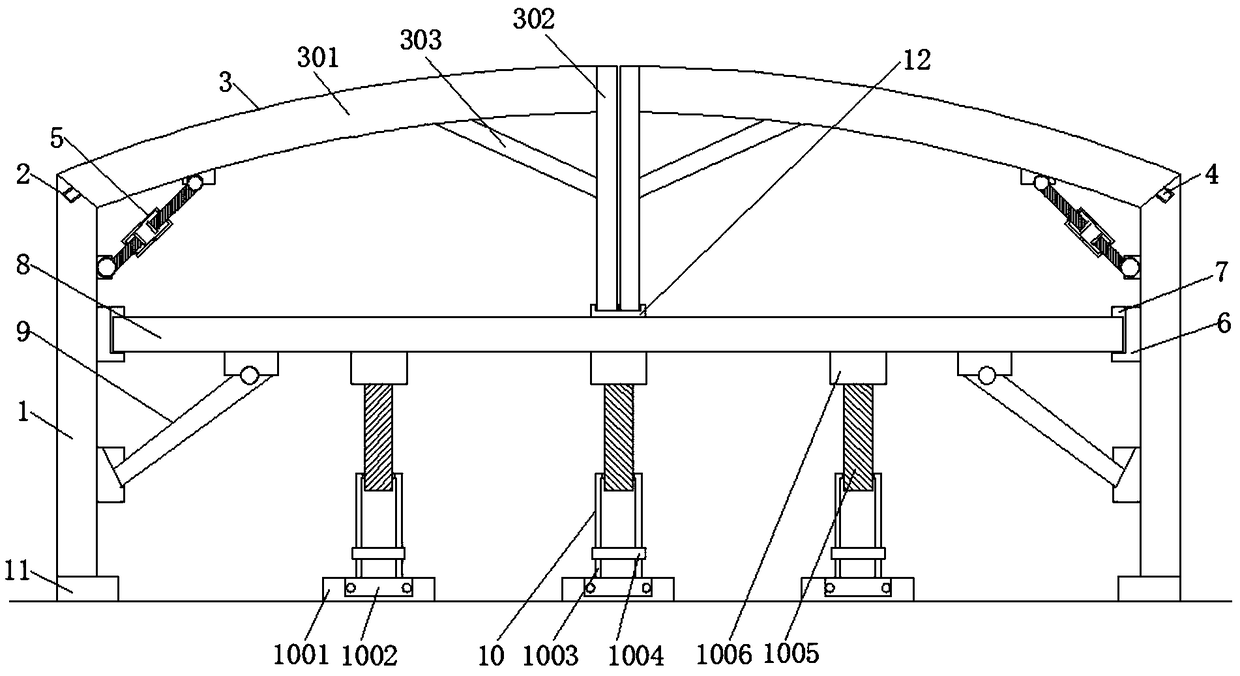

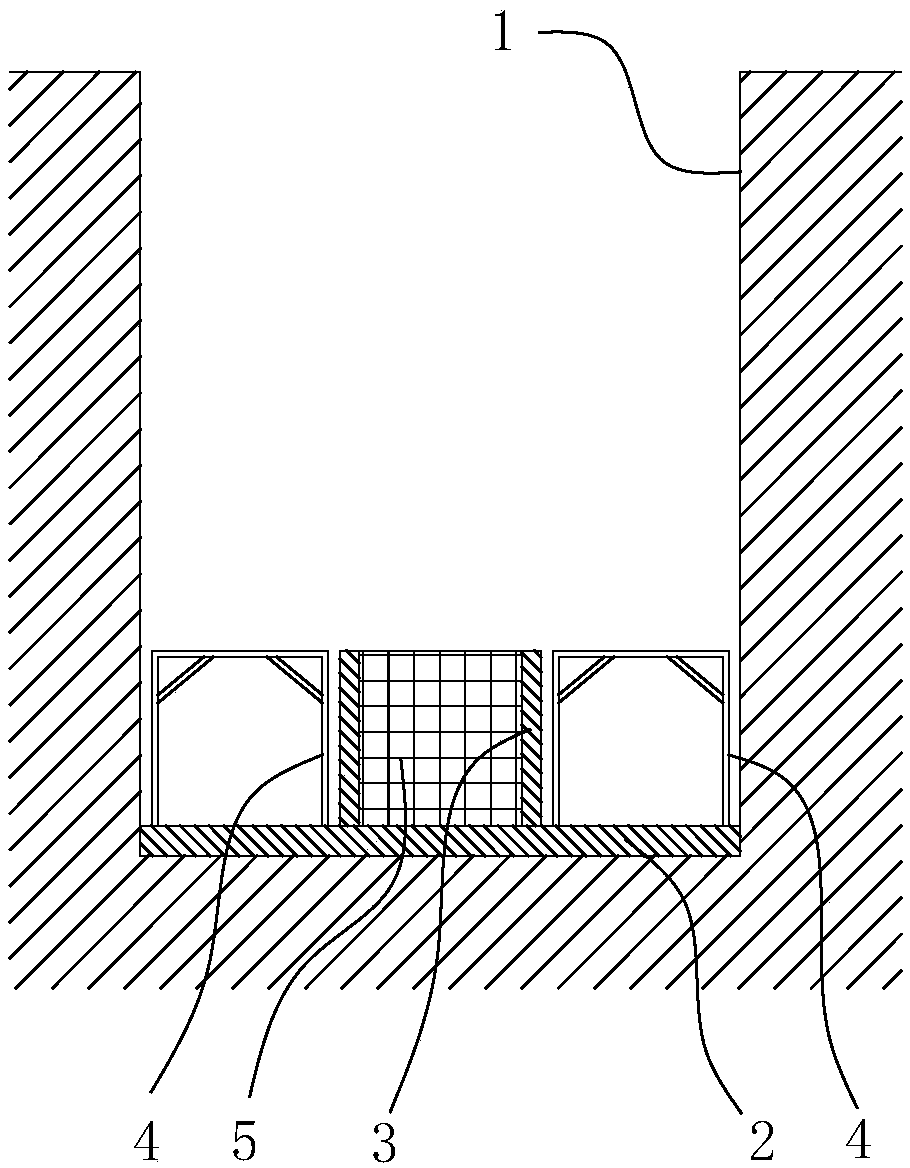

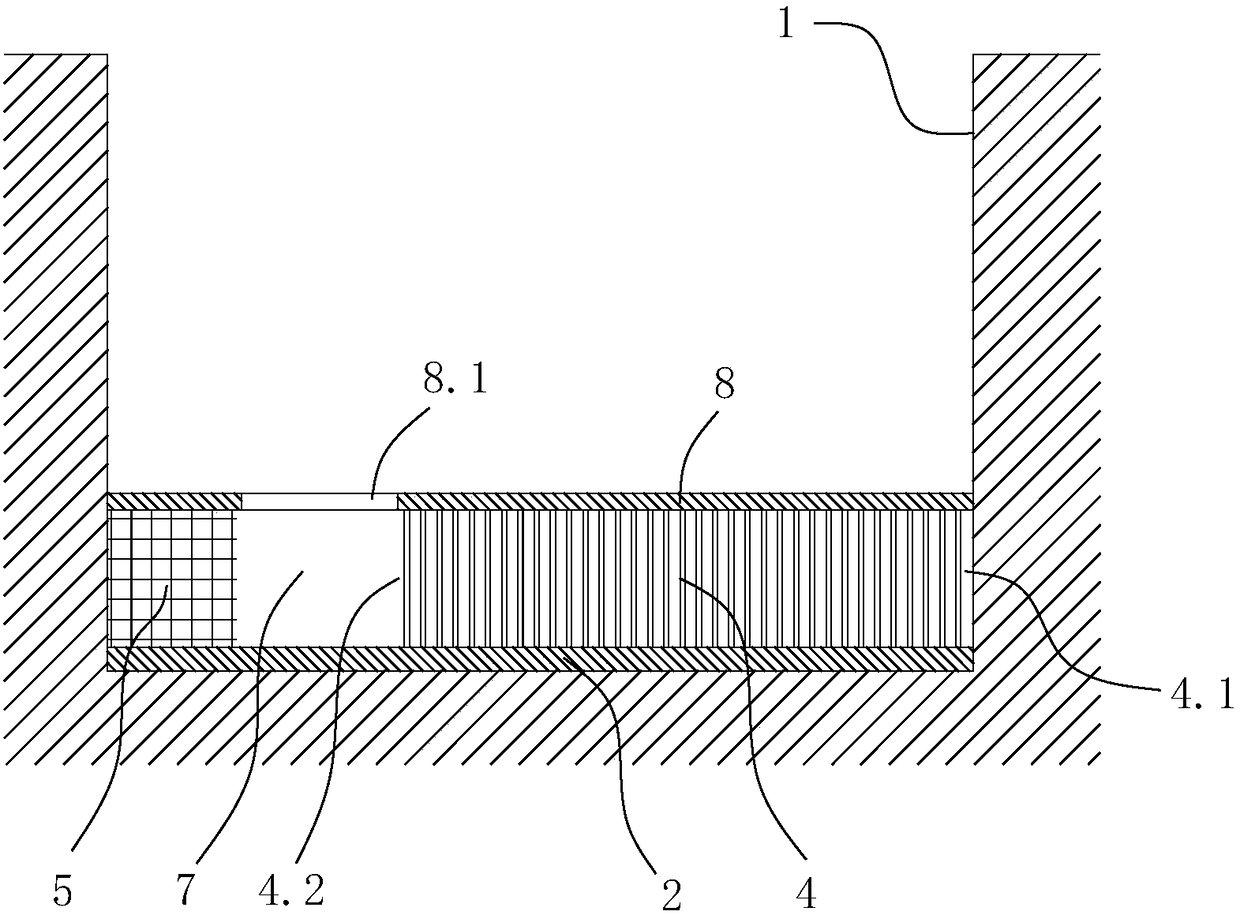

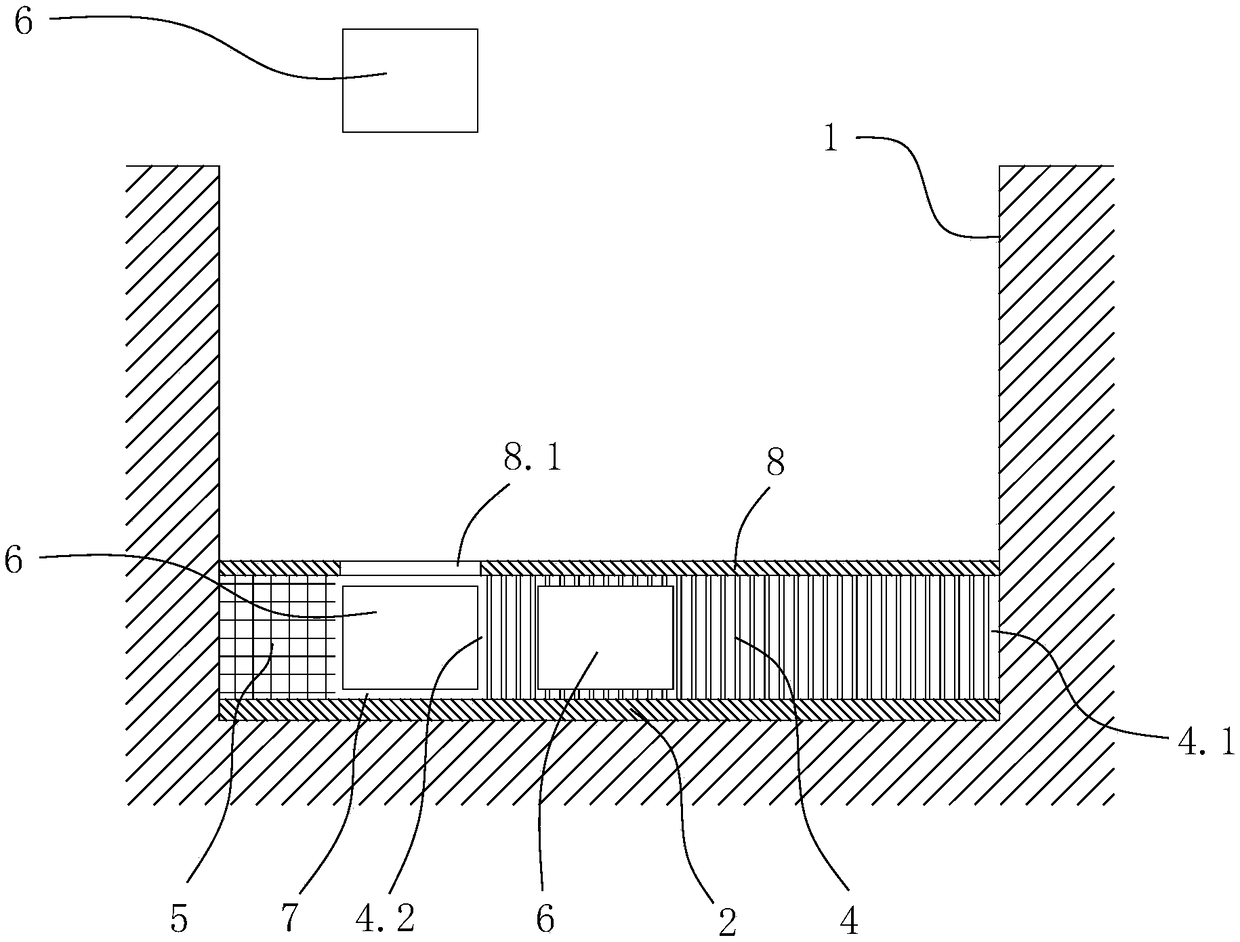

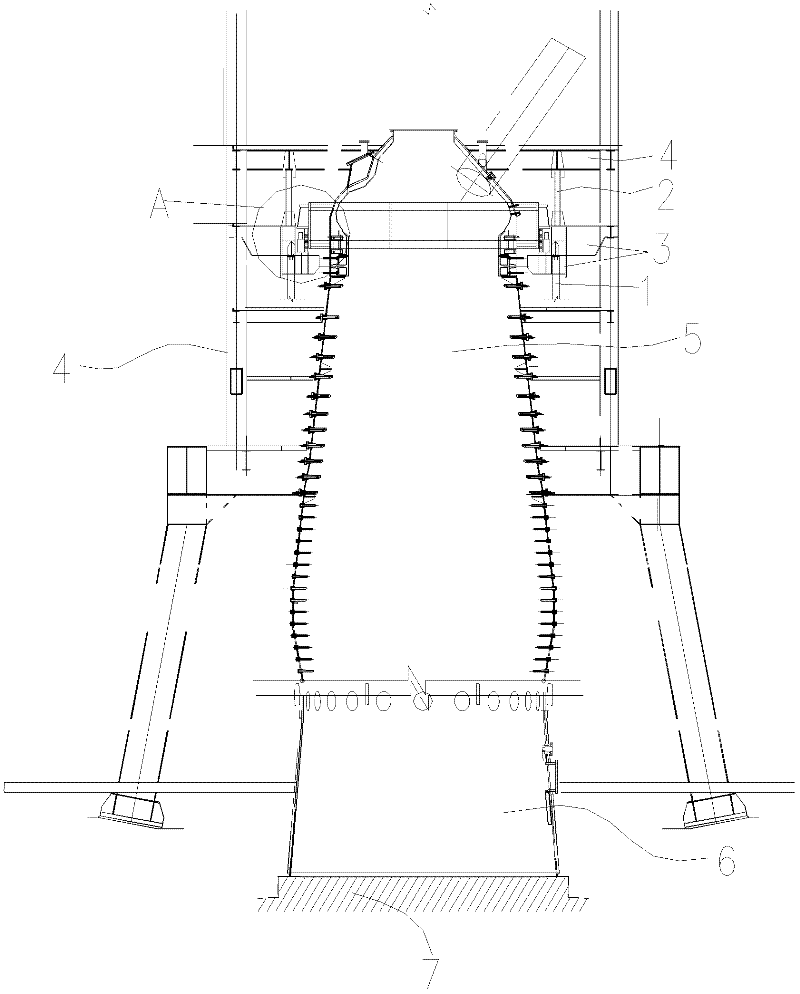

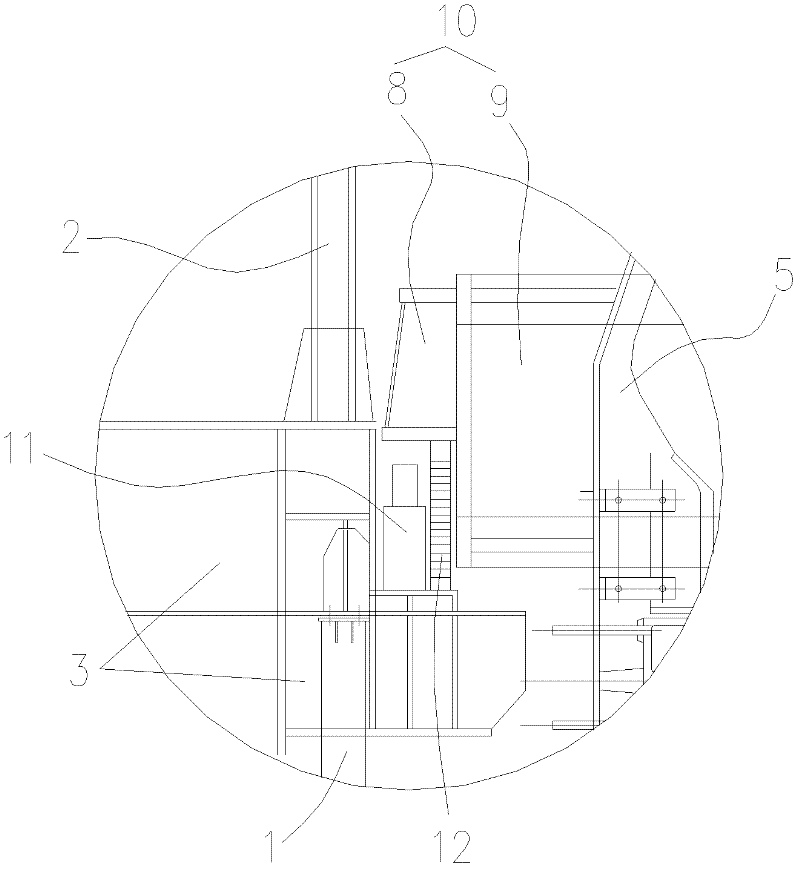

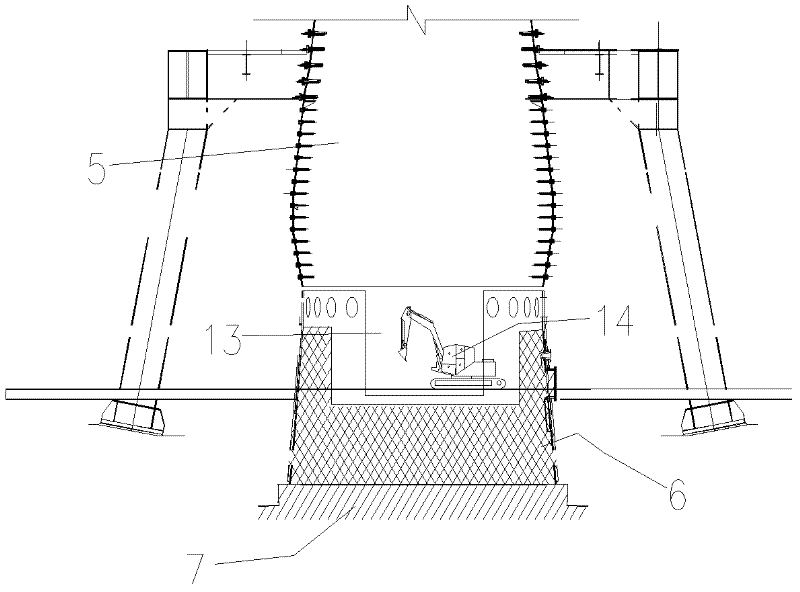

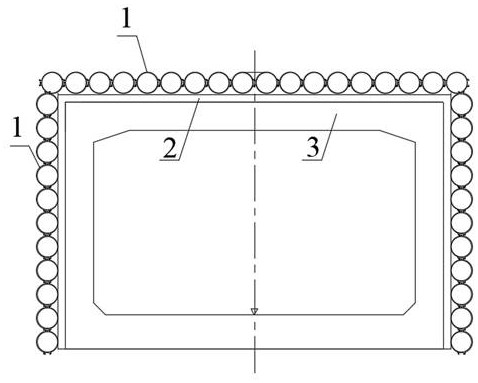

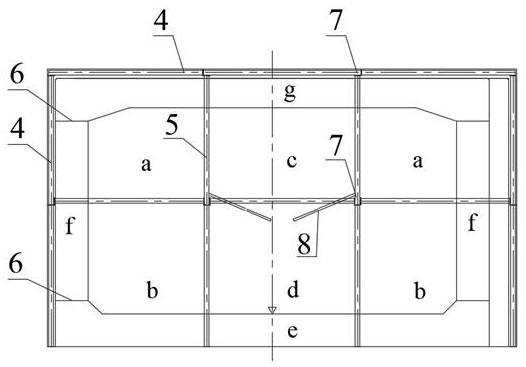

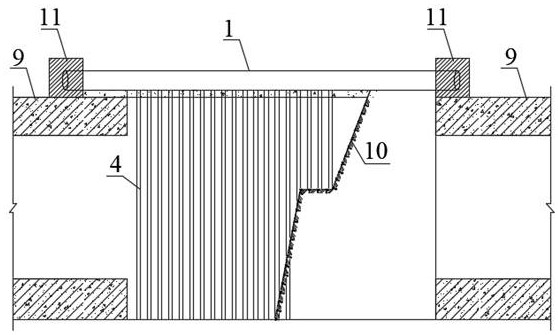

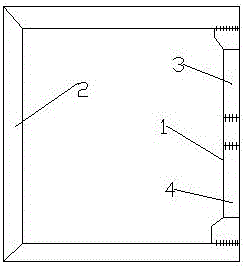

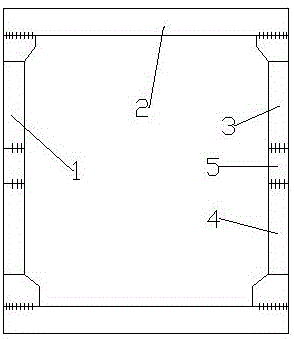

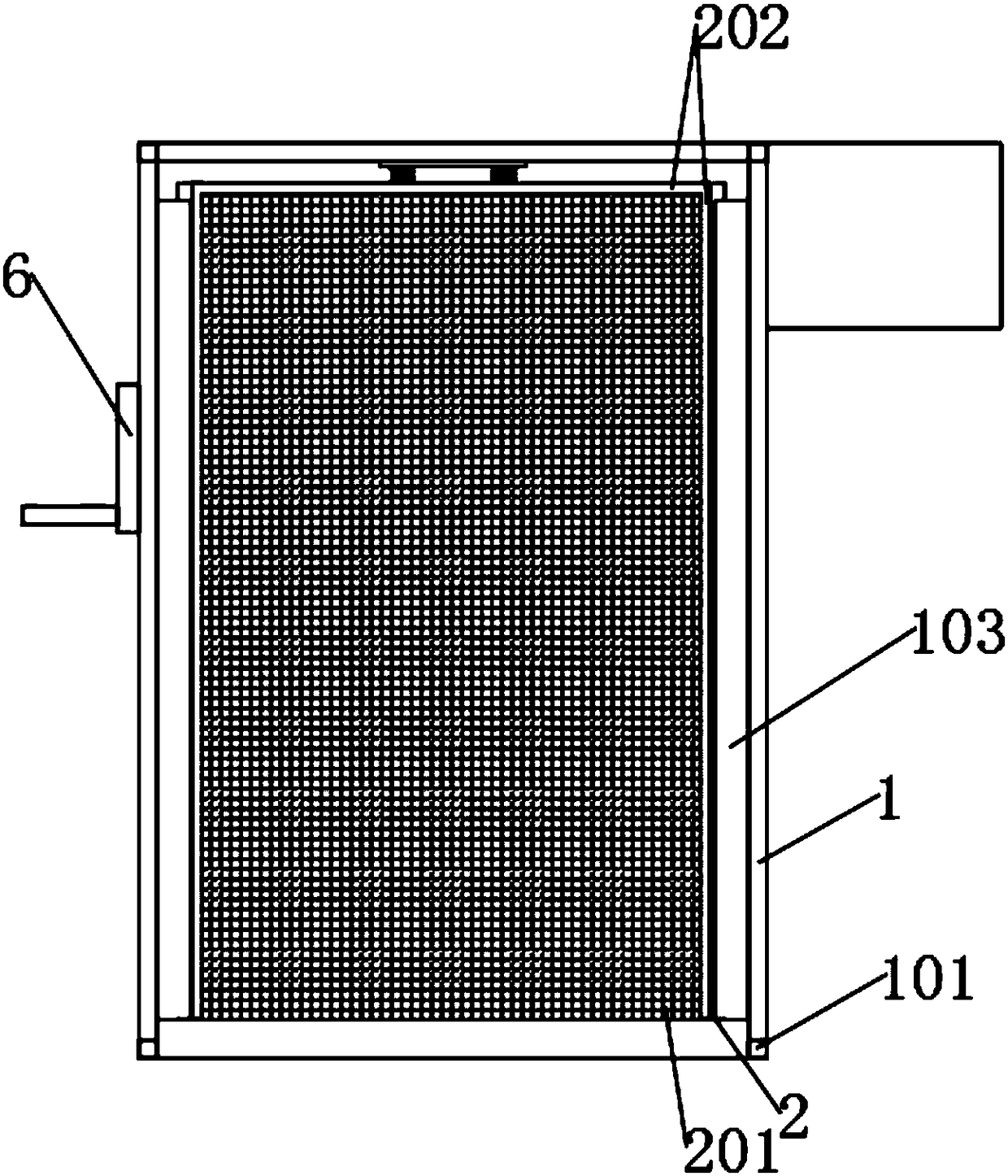

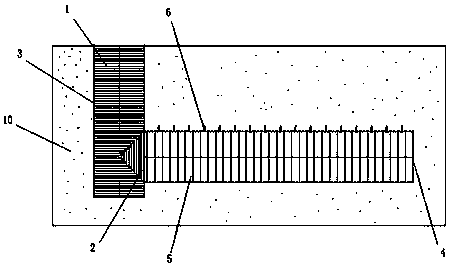

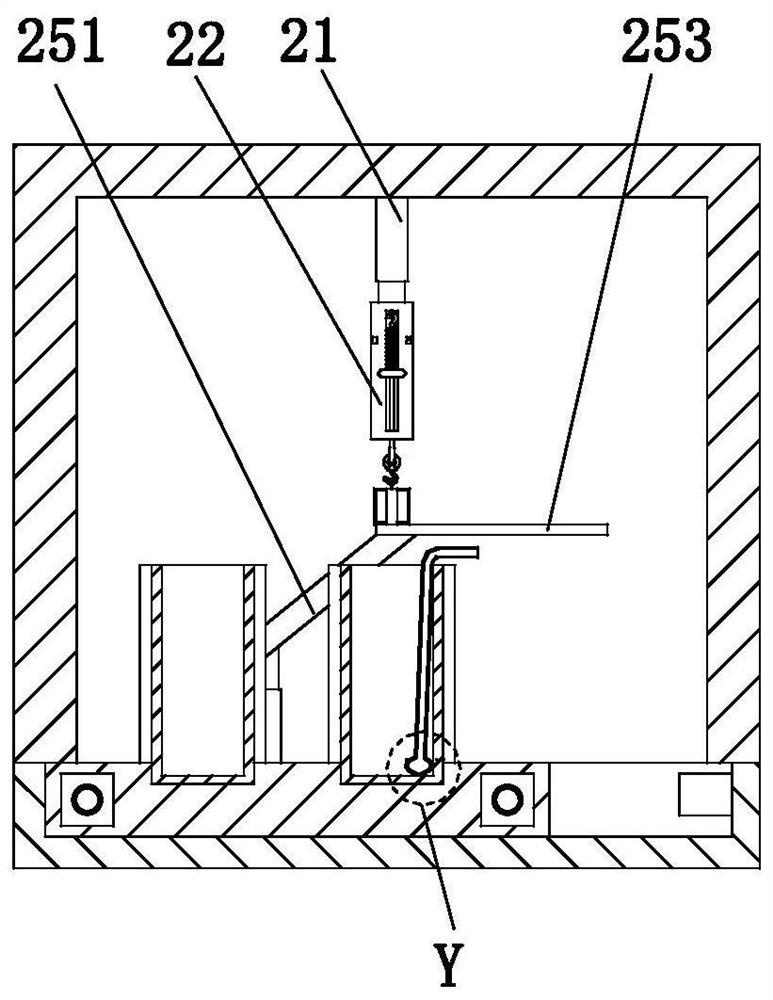

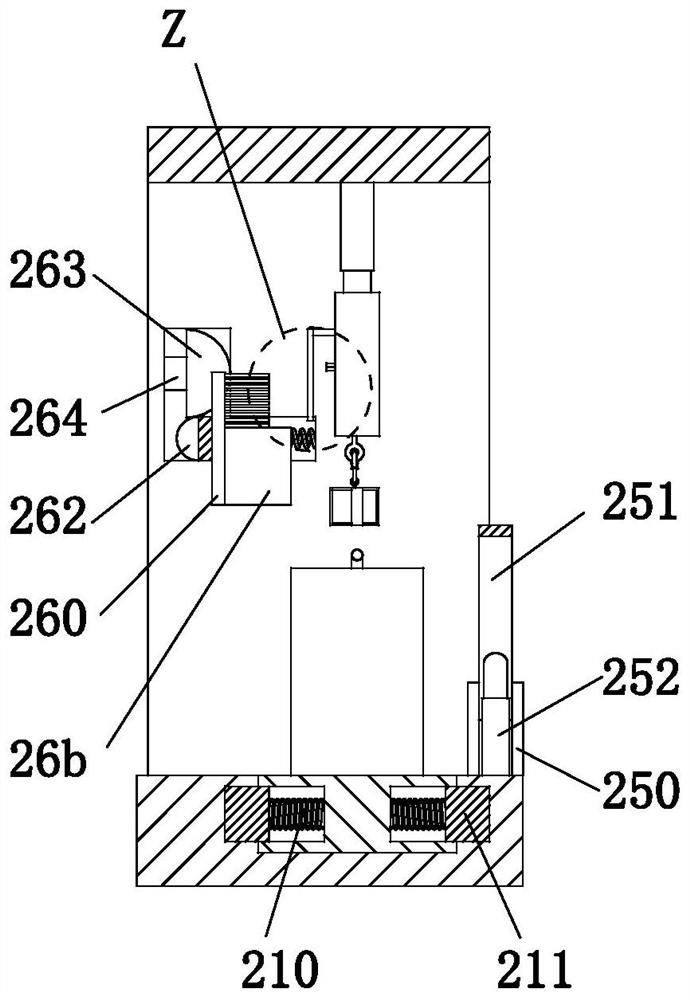

Movable internal supporting device for foundation pit support and using method of movable internal supporting device

The invention discloses a movable internal supporting device for foundation pit support and a using method of the movable internal supporting device, and belongs to the technical field of subway foundation pit support facilities. The movable internal supporting device and the using method are aim to solve the problems that the efficiency is low and the coordination difficulty is large in the construction process of an existing subway. The movable internal supporting device for foundation pit support includes an internal supporting structure body, the internal supporting structure body is placed in a subway foundation pit and plays the temporary supporting effect of subway foundation pit support, a construction space is provided for subway construction, a steel supporting structure is additionally arranged near the construction end, and the safety is improved during construction. The device can temporarily replace the steel supporting structure near the construction end, the steel supporting structure can be removed at the same time during concrete solidification of the gap between a fabricated subway member and a foundation pit support structure of the subway foundation pit, the construction speed is greatly increased, and the construction cycle is decreased; and the device is provided with a monorail crane to facilitate the disassembly and installation of the steel supportingstructure during construction, and the construction efficiency can be further improved.

Owner:哈尔滨工大建研工程咨询有限公司

Shield tunneling machine station and starting construction method

InactiveCN108316307AAvoid damageShorten the construction periodArtificial islandsExcavationsArchitectural engineeringShield tunneling

The invention provides a shield tunneling machine station and starting construction method, and aim at simultaneously carrying out construction of a station and starting of a shield tunneling machinein an excavated foundation pit. The method comprises the following steps of (1) construction of a base layer plate, and building of supporting frames and a scaffold; (2) assembly of the shield tunneling machine and entering of components into the foundation pit; and (3) construction of upper layer plates. According to the shield tunneling machine station and starting construction method, construction of the upper layer plates can be carried out while the assembly components of the shield tunneling machine enter the foundation pit one by one for assembly, so that the structure of the station isconstructed layer by layer, construction of the station is carried out, the assembly and starting of the shield tunneling machine and construction of the station can be carried out at the same time,mutual waiting is not needed, the progress of tunnel construction is guaranteed, meanwhile, the construction period of the station is greatly shortened, the influence on the ground road is reduced, and walking convenience is improved; the shield tunneling machine is assembled in the supporting frames, and the supporting frame can protect the shield tunneling machine, so that the situation that theshield tunneling machined is damaged due to the fact that a falling object falls onto the shield tunneling machine when the station that construction is carried out at the same time is avoided; and meanwhile, the supporting frames can play a temporary supporting role of the scaffold, the upper layer plate are constructed, construction of the station is facilitated, and the construction speed of the station is ensured.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

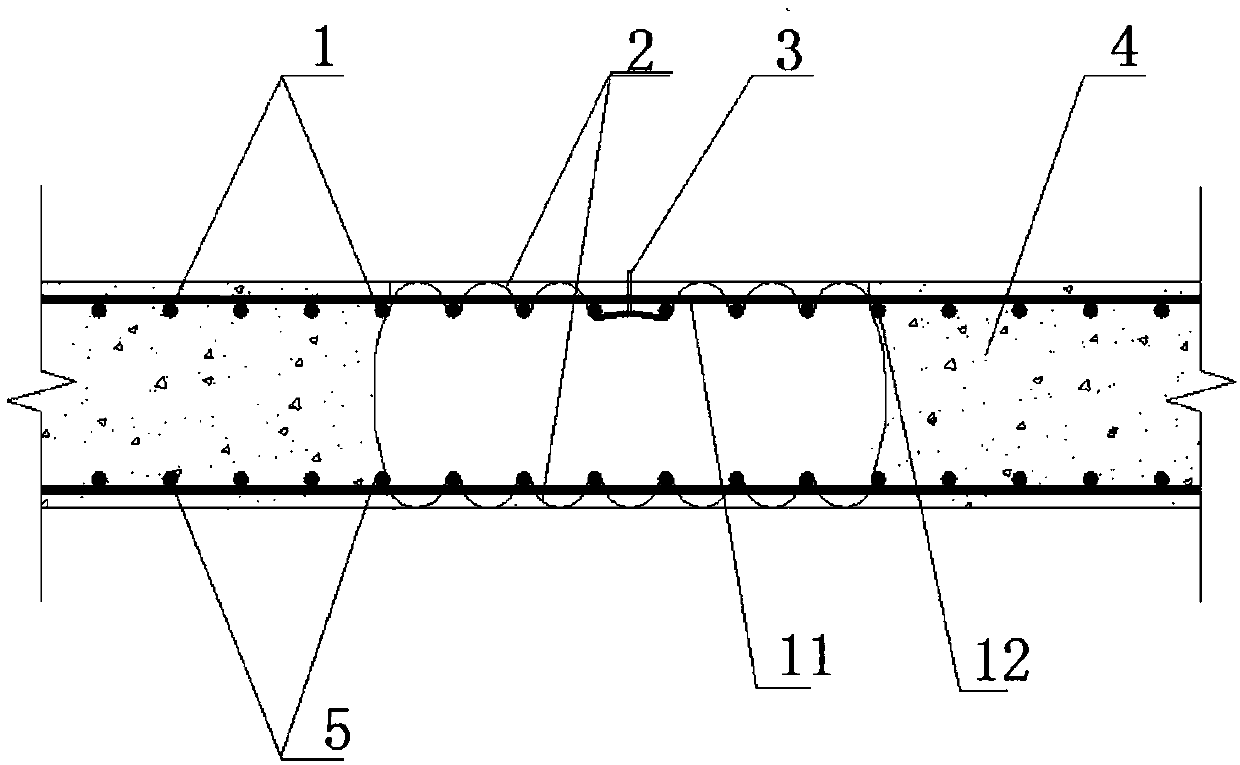

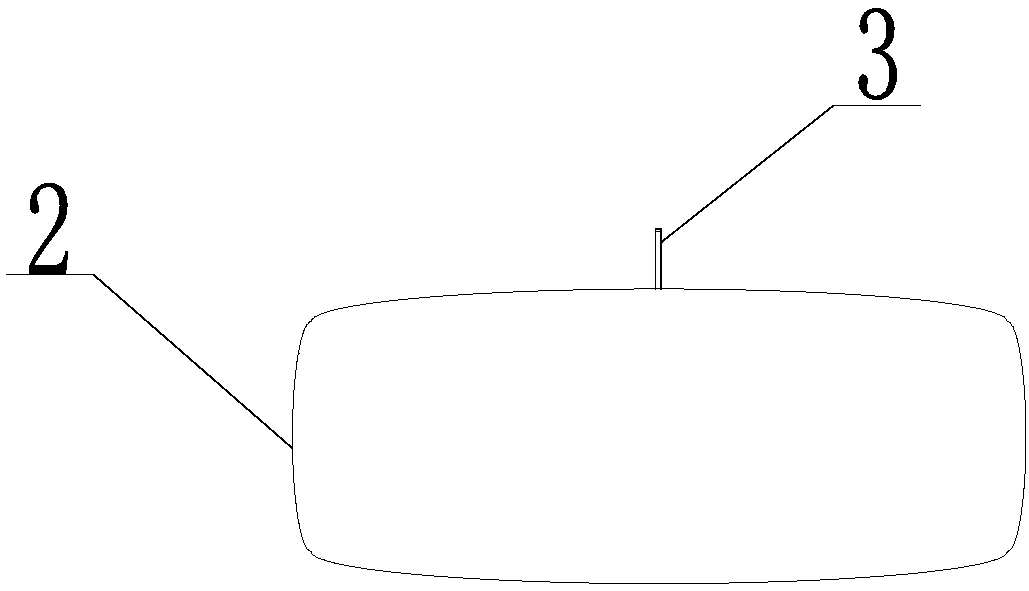

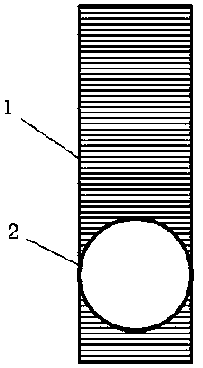

Post-pouring belt concrete blocking device and using method thereof

PendingCN107700846AAct as a temporary supportPlay the role of interceptionBuilding material handlingArchitectural engineeringRebar

The invention discloses a post-pouring belt concrete blocking device and a using method thereof. The post-pouring belt concrete blocking device comprises a post-pouring belt upper steel bar, a post-pouring belt lower steel bar and a rubber inflating bag. When the post-pouring belt concrete blocking device is used, the post-pouring belt lower steel bar is bound and fixed, the rubber inflating bag which is inflated with 70%-80% of air is placed at the upper end of the post-pouring belt lower steel bar, and the post-pouring belt upper steel bar is mounted and bound at the upper end of the rubberinflating bag; then the rubber inflating bag is inflated with 100% of air; and concrete is poured to the two sides of the rubber inflating bag, and when the concrete strength reaches the formwork removing condition, air in the rubber inflating bag is released, and then the rubber inflating bag is taken out. The clearance between the post-pouring belt steel bars can be blocked after the rubber inflating bag is inflated, so that an interception effect is achieved when concrete is poured into a post-pouring belt; as the blocking device of post-pouring belt concrete, the rubber inflating bag has the characteristic of convenient assembly and disassembly; and the size of the rubber inflating bag after deflating is reduced, the rubber inflating bag can be directly pulled out from the clearance ofthe steel bars and can be reused, the construction period is shortened, the construction difficulty of workers is reduced, and meanwhile, materials are saved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

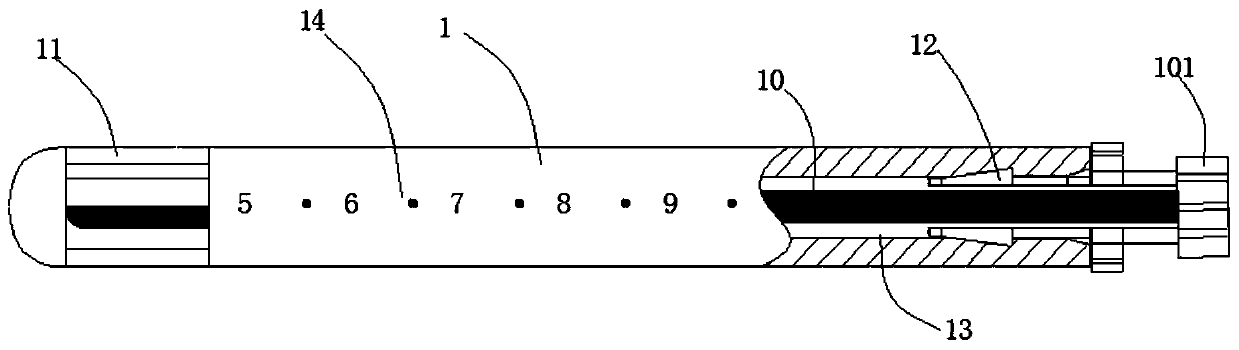

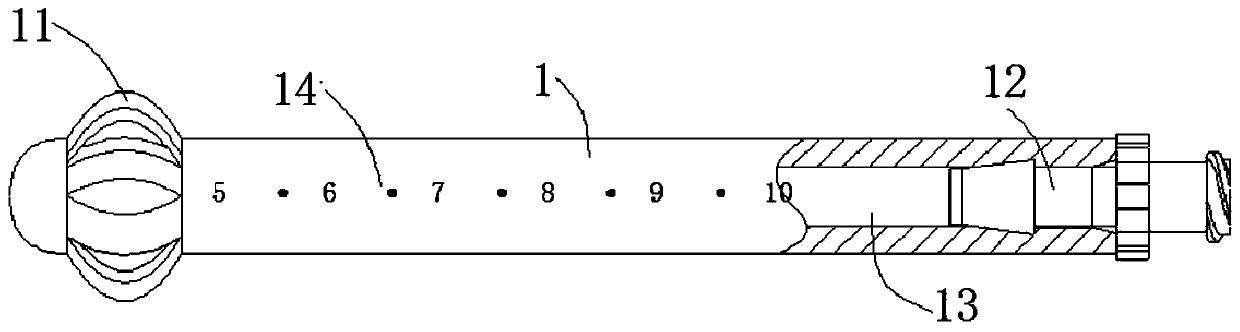

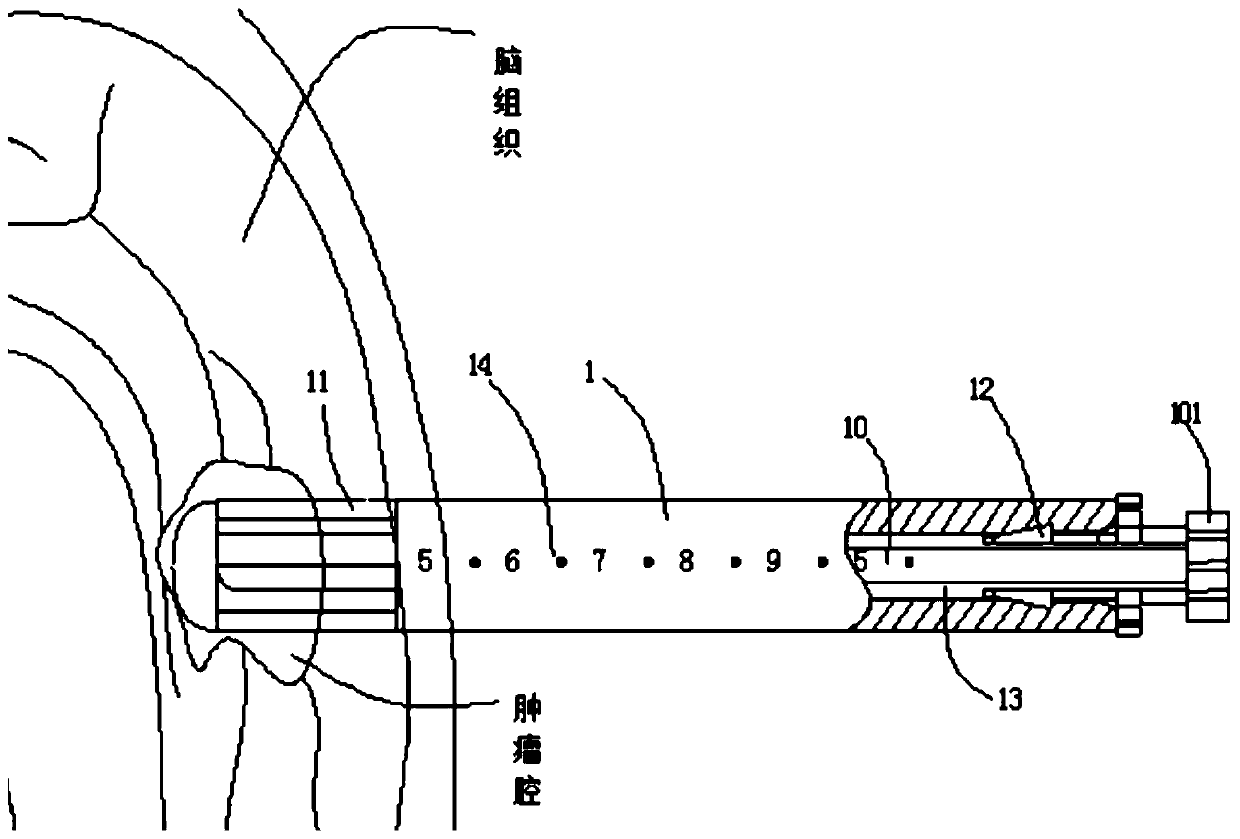

Intracranial cerebrospinal fluid drainage tube

PendingCN110124184AMaintain drainage functionAct as a temporary supportBalloon catheterWound drainsDislocationIntracranial pressure

The invention discloses an intracranial cerebrospinal fluid drainage tube in the technical field of medical devices. An inner cavity of the drainage tube is transversely provided with a guide needle.The right side of the guide needle runs through a Luer taper and extends outside the right side of the drainage tube, the left side of the guide needle is connected with the left side of the drainagecavity, and the right side of the guide needle is provided with a Luer block shot; the front end face of the drainage tube is provided with a scale line from left to right in turn, and the left side of the drainage tube is provided with external expansion structures in an annular manner. The drainage tube has the advantages that through the external expansion structures, the drainage tube can expand outward to fill a tumor cavity in the early stage of tumor removal and plays a role in temporarily supporting and occupying a space, and the drainage tube can be fixed to prevent displacement and dislocation. With the process of continuous drainage and reset of a brain tissue, the brain tissue is contracted by squeezing the external expansion structures, and the elastic external expansion structures are contracted and gathered; at the same time, gaps between the external expansion structures persistently exist. The drainage tube maintains the drainage function continuously and the stabilityof the intracranial pressure is maintained.

Owner:深圳市慧极创新医疗科技有限公司

Method for correcting and resetting blast furnace body

ActiveCN102409119ARealize correction resetRemove riseBlast furnace componentsBlast furnace detailsOffset distanceDislocation

The invention discloses a method for correcting and resetting blast furnace body, which can obviously shorten the construction period; the method mainly comprises: A, dividing the blast furnace above the furnace base into a furnace bottom and an upper furnace body, then lifting the upper furnace body and fixing; B, removing the furnace bottom on the furnace base; C, determining a theoretical center point of the furnace bottom on the furnace base and the theoretical elevation of the furnace bottom; D, according to the theoretical center point of the furnace bottom and the theoretical elevationof the furnace bottom, installing a new furnace bottom on the furnace base; E, determining the offset distance between the orthographic projection of the top center of the upper furnace body on the furnace base and the theoretical center point of the furnace bottom on the furnace base; F, adjusting the upper furnace body so that the axial direction of the upper furnace is parallel to the new furnace bottom; the offset distance is reduced to less than or equal to H / 1000; wherein H is the height of the furnace, and the dislocation degree between the outer wall of the upper furnace body and the outer wall of the new furnace bottom can satisfy the installing requirement of the blast furnace; G, connecting the upper furnace body with the new furnace bottom on the furnace base.

Owner:CHINA 19TH METALLURGICAL CORP

Auxiliary support based on high-altitude outdoor air conditioner outdoor unit installation

InactiveCN111981586ARepair in timePlay a warning effectSpace heating and ventilation safety systemsLighting and heating apparatusPedestrianElectrical and Electronics engineering

The invention provides an auxiliary support based on high-altitude outdoor air conditioner outdoor unit installation, and relates to the technical field of air conditioner outdoor unit installation. The auxiliary support solves the problems that an existing support used for supporting an air conditioner outdoor unit is not provided with a corresponding warning structure, and if an air conditioneroutdoor unit supporting frame causes the air conditioner outdoor unit to fall due to installation factors or corrosion factors, residents cannot know the situation immediately, and great potential safety hazards exist. The auxiliary support based on high-altitude outdoor air conditioner outdoor unit installation comprises fixing angle steel, and a set of left side supporting angle steel and a setof right side supporting angle steel are fixedly installed on the left side and the right side of the inwards-concave end of the fixing angle steel through a set of fastening bolts correspondingly; and when a rectangular pressing plate is pressed down by the air conditioner outdoor unit, an insulating inserting piece slides downwards along a through inserting opening formed in the top end face andthe bottom end face of a rectangular shell, so that at the moment, a power source in the rectangular shell is switched on, a buzzer makes a high-decibel sound, residents are reminded to maintain in time, and the warning effect on pedestrians close to a road on the lower side of the rectangular shell is achieved.

Owner:厉建锦

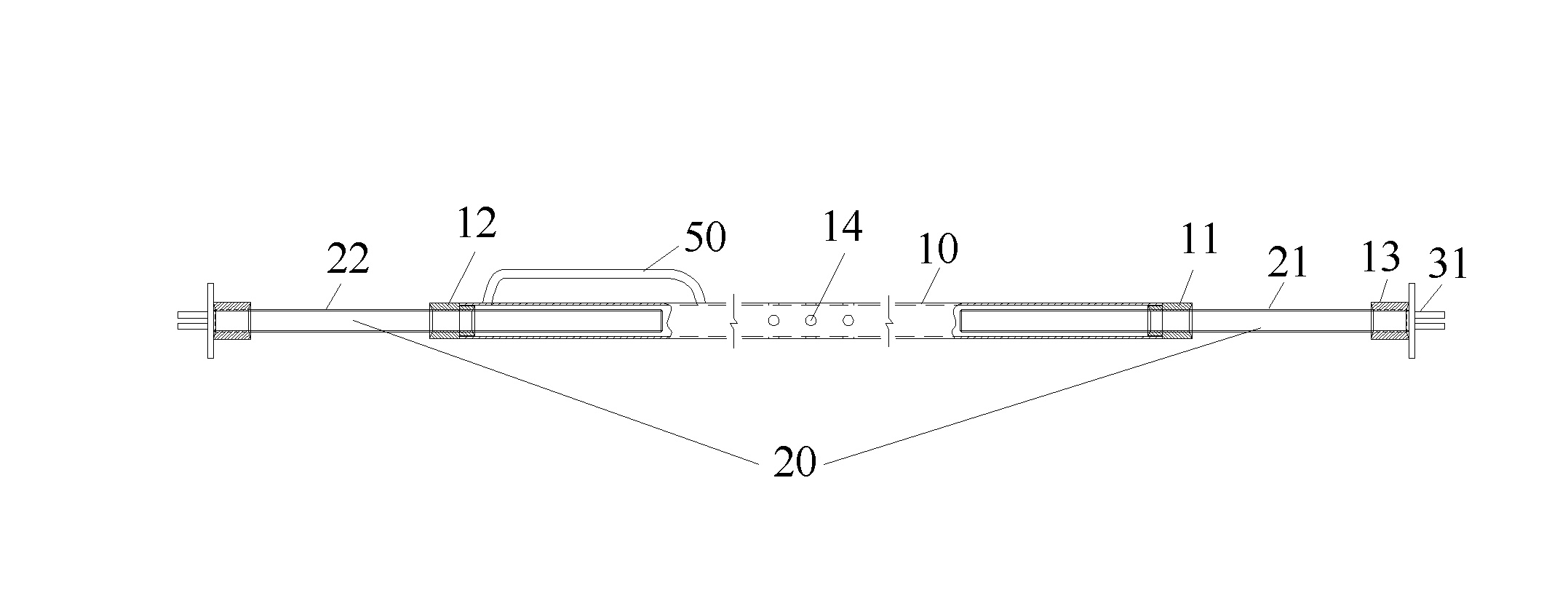

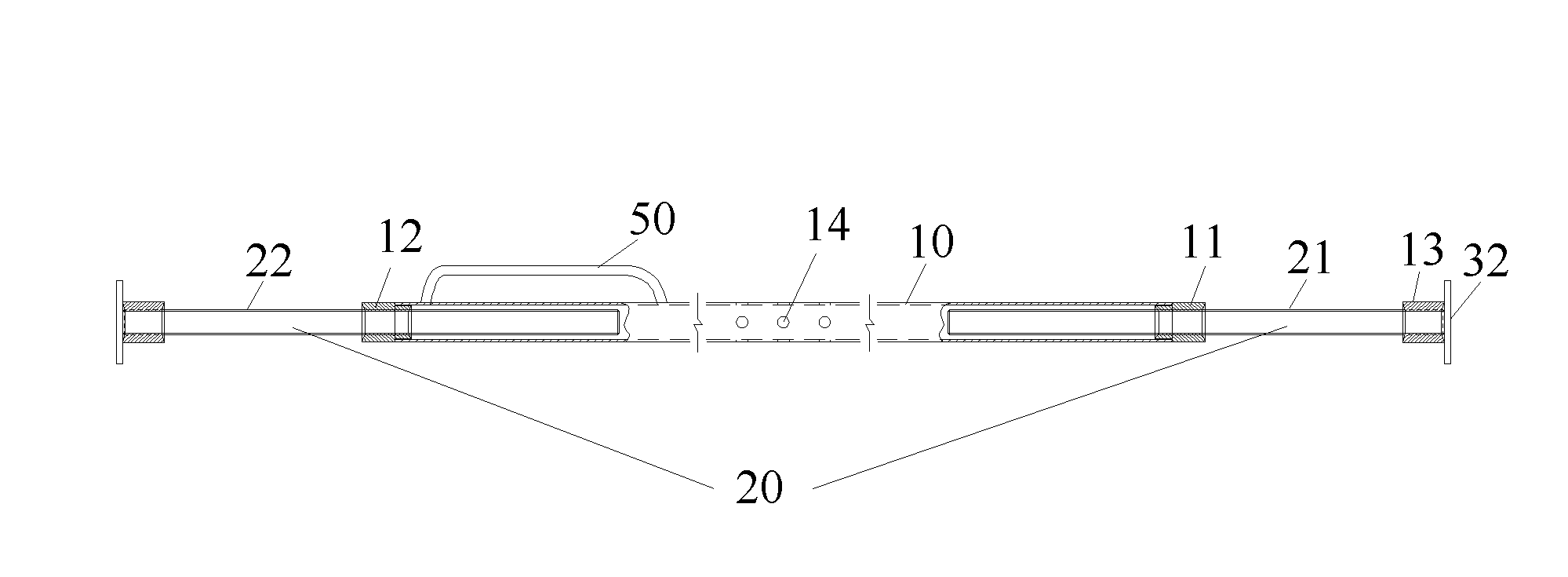

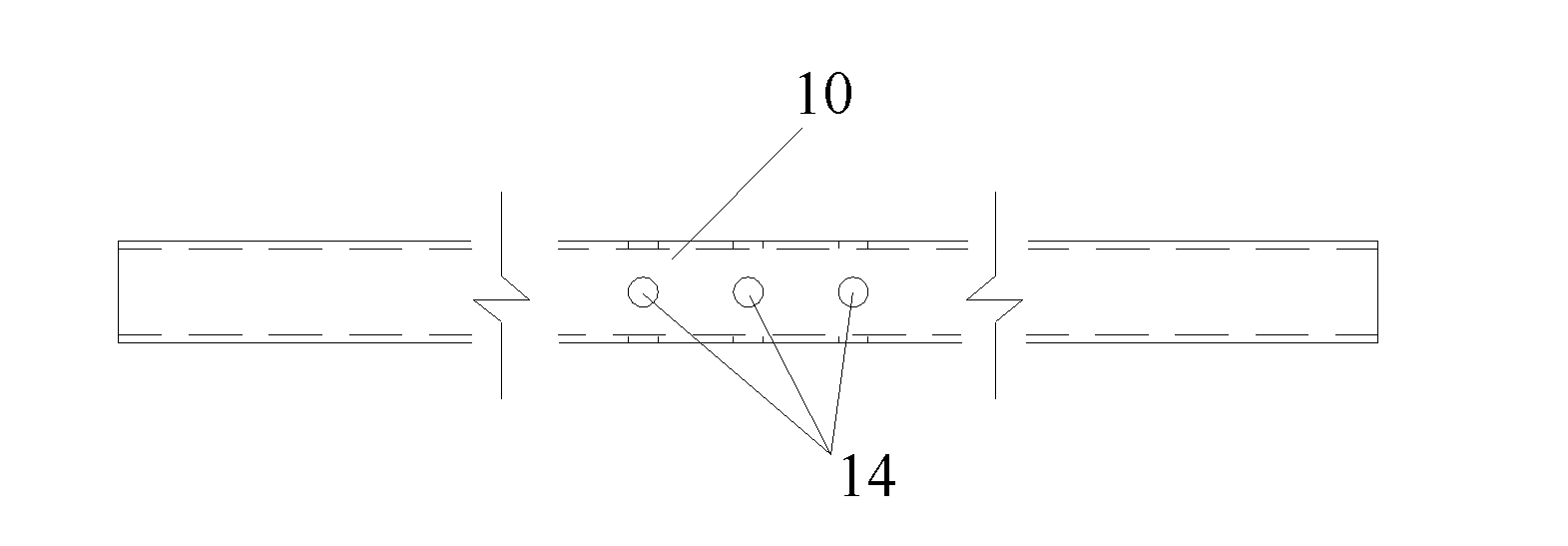

Support rod component

InactiveCN103133035ASolve the problem of unstable bearing capacityAct as a temporary supportMining devicesEngineeringBearing capacity

The invention provides a support rod component. The support rod component comprises a main pipe, a support rod and end portions which are arranged on the main pipe in an extensible mode. The support rod component are supported in a support or a tunnel, provides extra bearing force for the support, solves the problem that the bearing force of the support is unstable in a period of changing the support or repairing an old tunnel, plays a temporary supporting role for the support or the tunnel, supports a deformed support and enables the support to resile.

Owner:STATE GRID CORP OF CHINA +1

Mining method tunnel supporting structure capable of downward penetrating operating G-series high-speed train and construction method thereof

PendingCN111997646AStrong ability to control settlementConstruction safetyUnderground chambersTunnel liningArchitectural engineeringSteel frame

The invention discloses a mining method supporting structure capable of downward penetrating an operating G-series high-speed train. The mining method supporting structure comprises a pipe curtain structure, a preliminary bracing and a secondary lining; the secondary lining is positioned on the inner side of the preliminary bracing; the pipe curtain structure is positioned on the outer side of thepreliminary bracing and is distributed on the top and side edge of the preliminary bracing; temporary support steel frames transversely and longitudinally arranged in a staggered manner are further arranged in the tunnel and serve as tunnel excavated temporary supports; end ring beam structures are arranged on the tops of constructed section structures at the two ends of the tunnel; and the two ends of the pipe curtain structure are fixed to the corresponding end ring beam structures as support points. The invention further discloses a construction method of the mining method supporting structure capable of downward penetrating an operating G-series high-speed train. Preliminary bracing, temporary support and secondary lining are combined to serve as a tunnel support structure; and in addition, a pipe curtain is adopted as pre-supporting, a segment excavation construction method is adopted in the tunnel, and compared with a common mining method tunnel, the mining method supporting structure has the advantages of being high in sedimentation control capacity and safe and reliable in construction.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

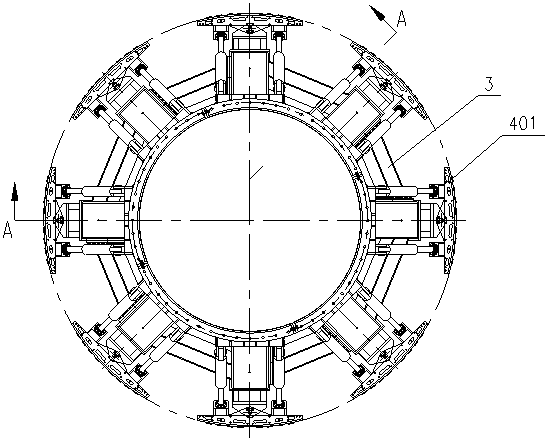

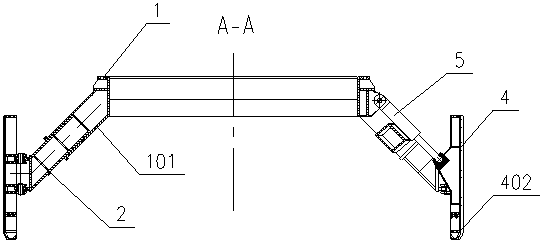

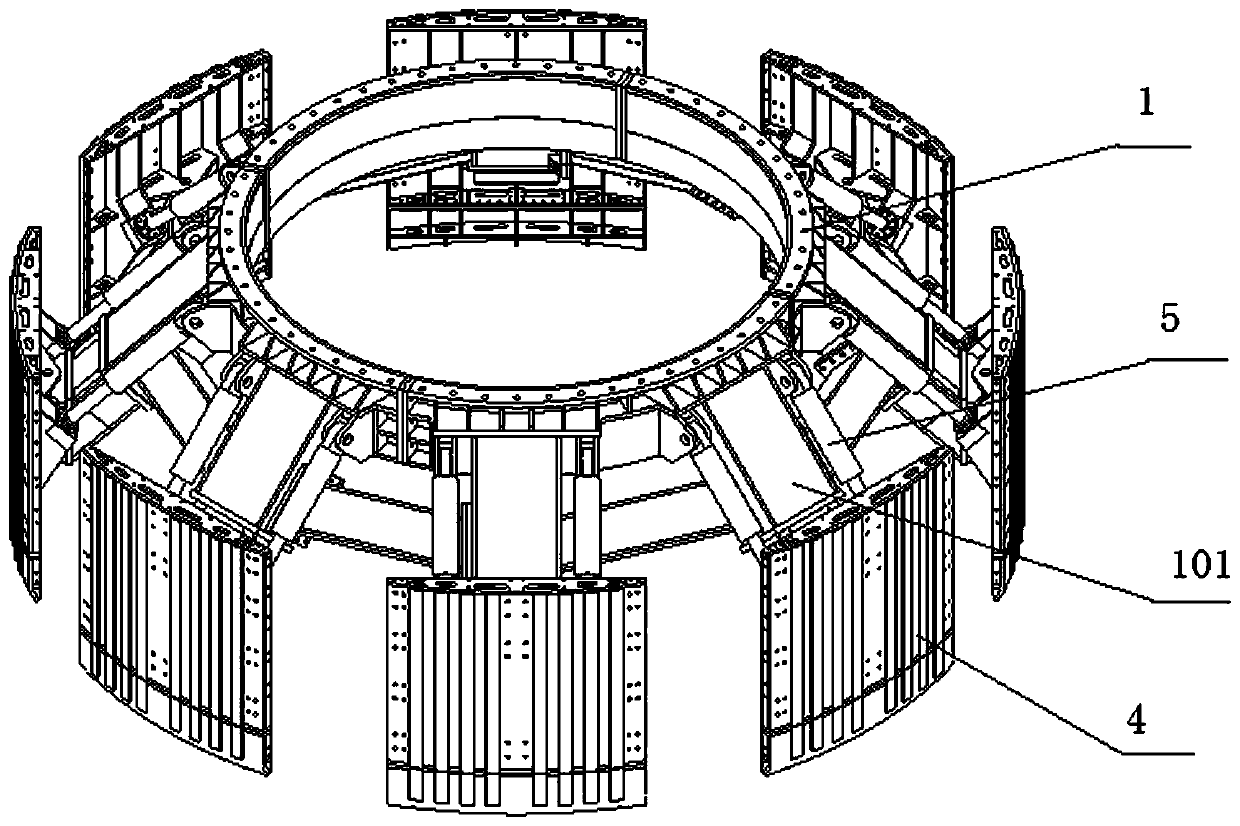

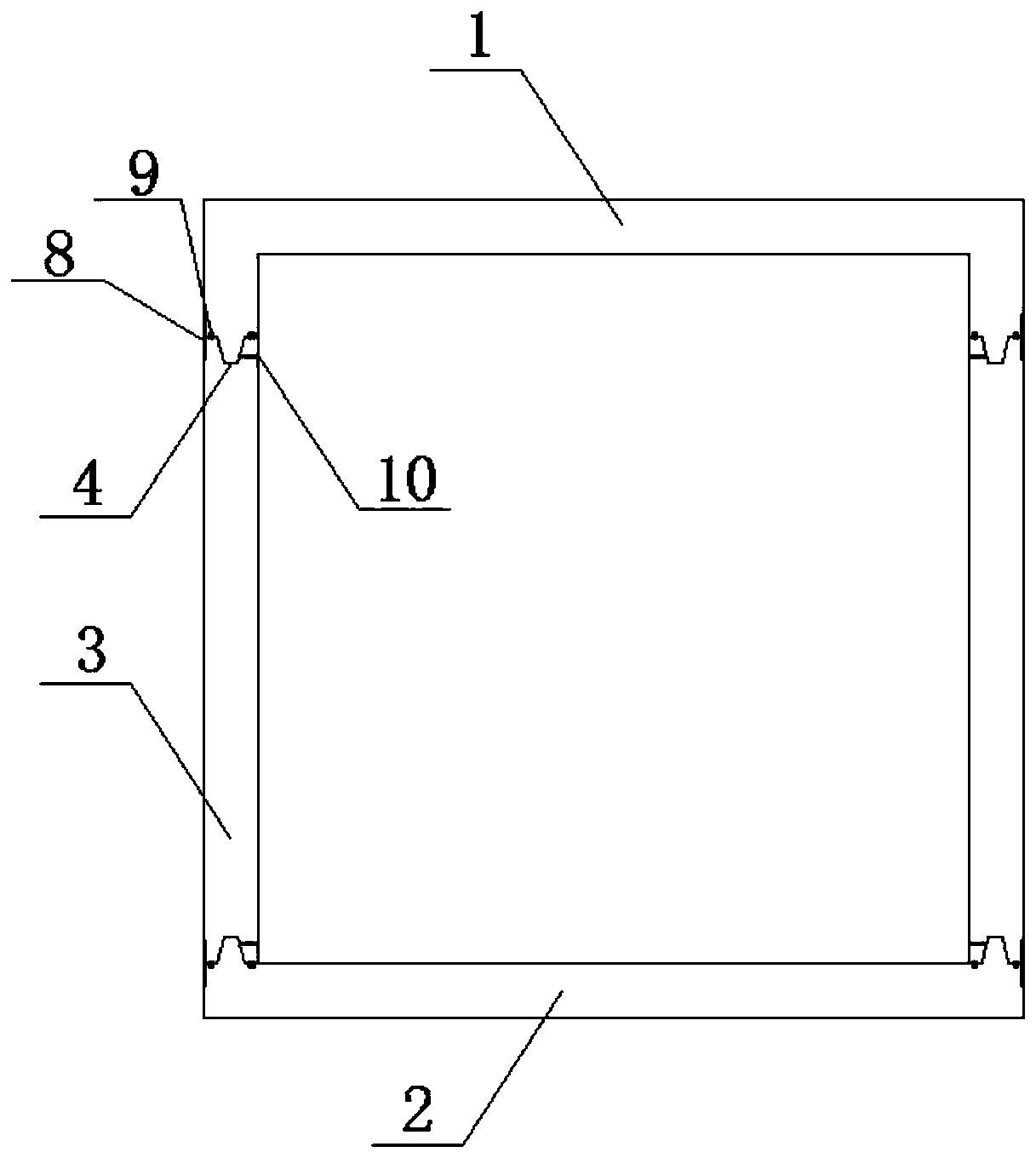

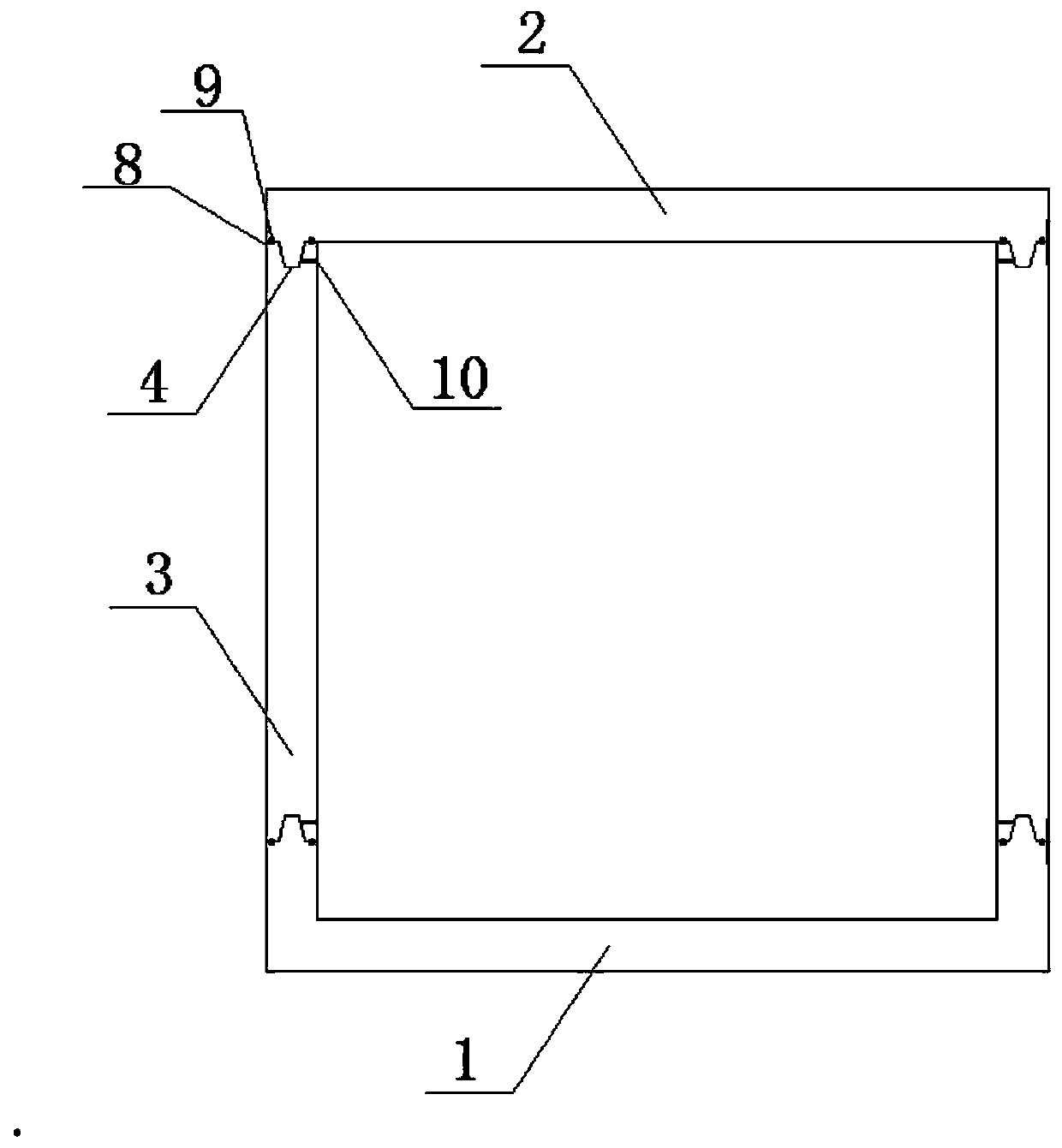

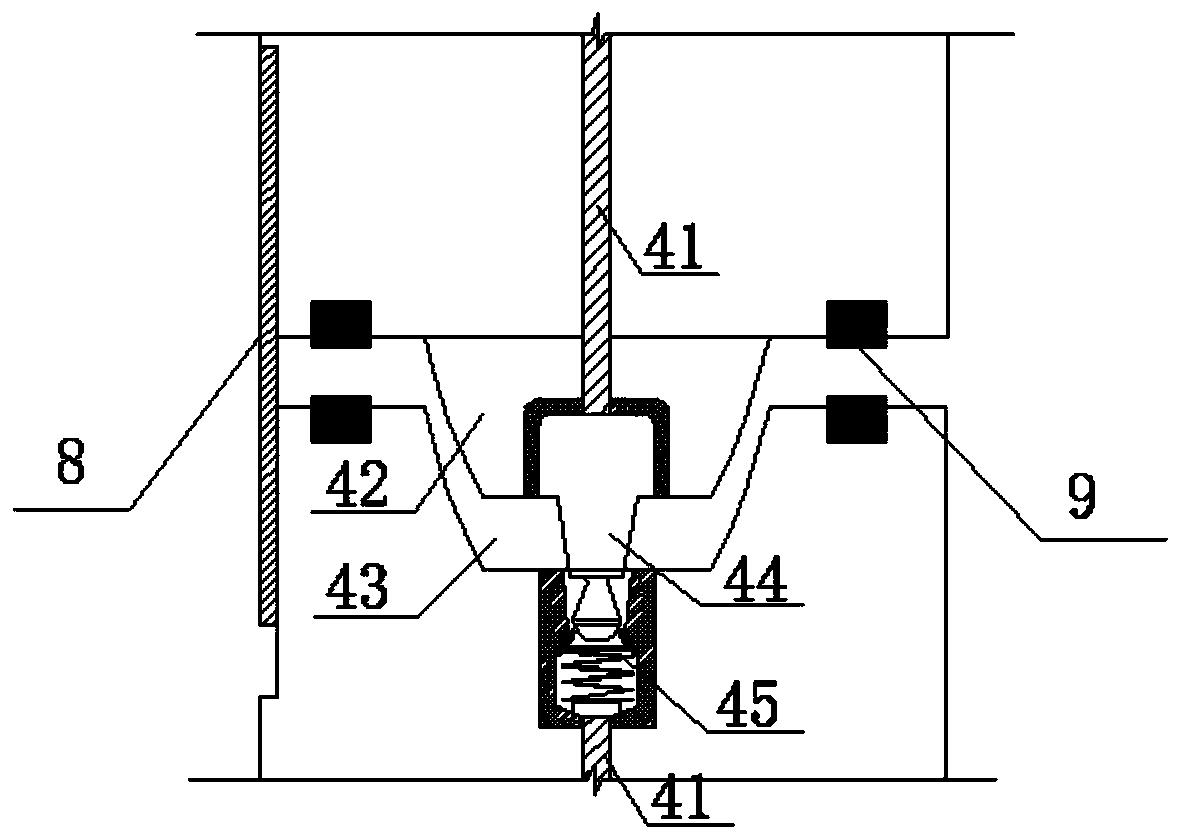

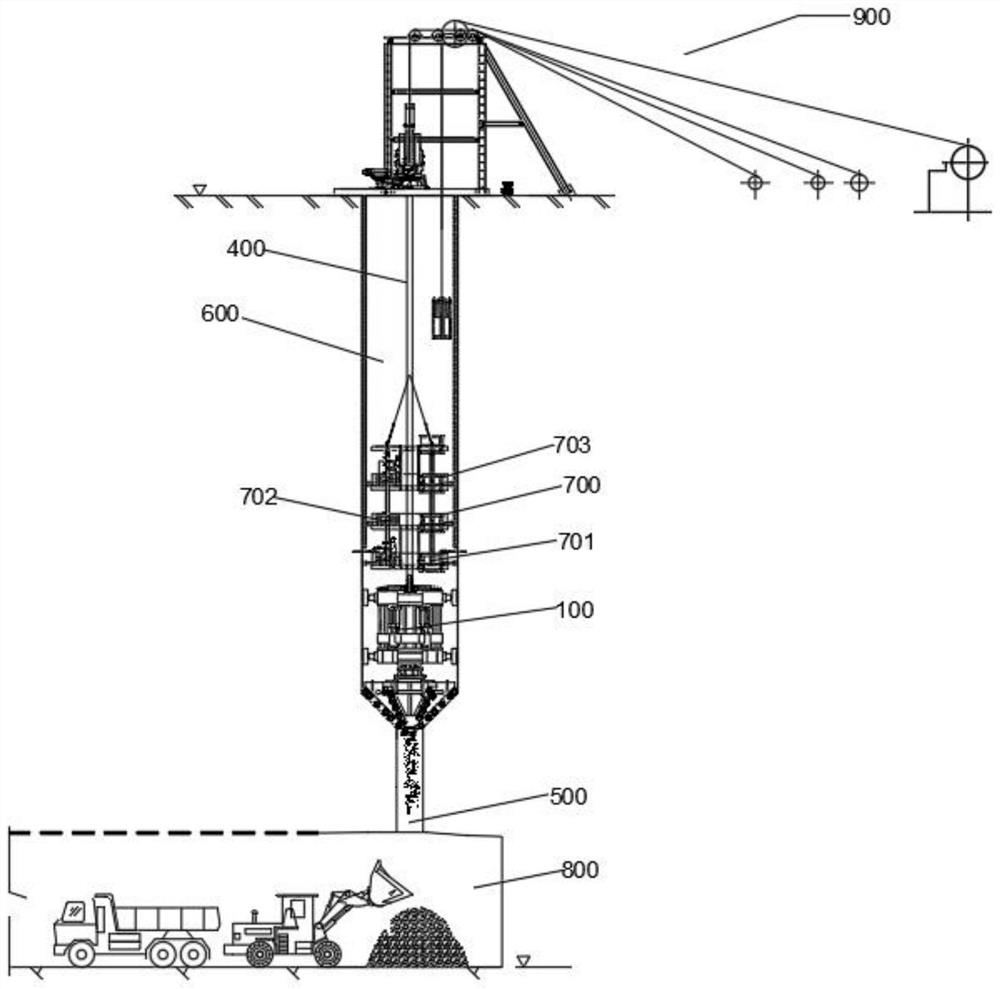

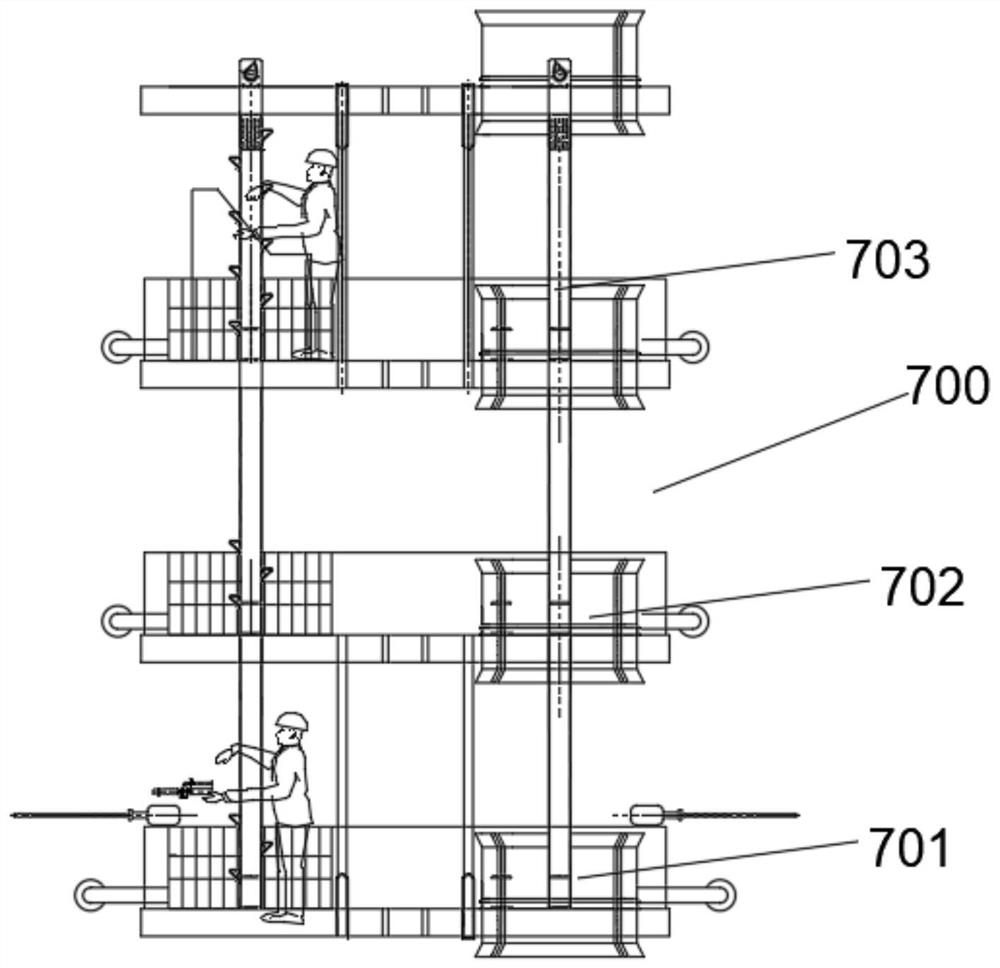

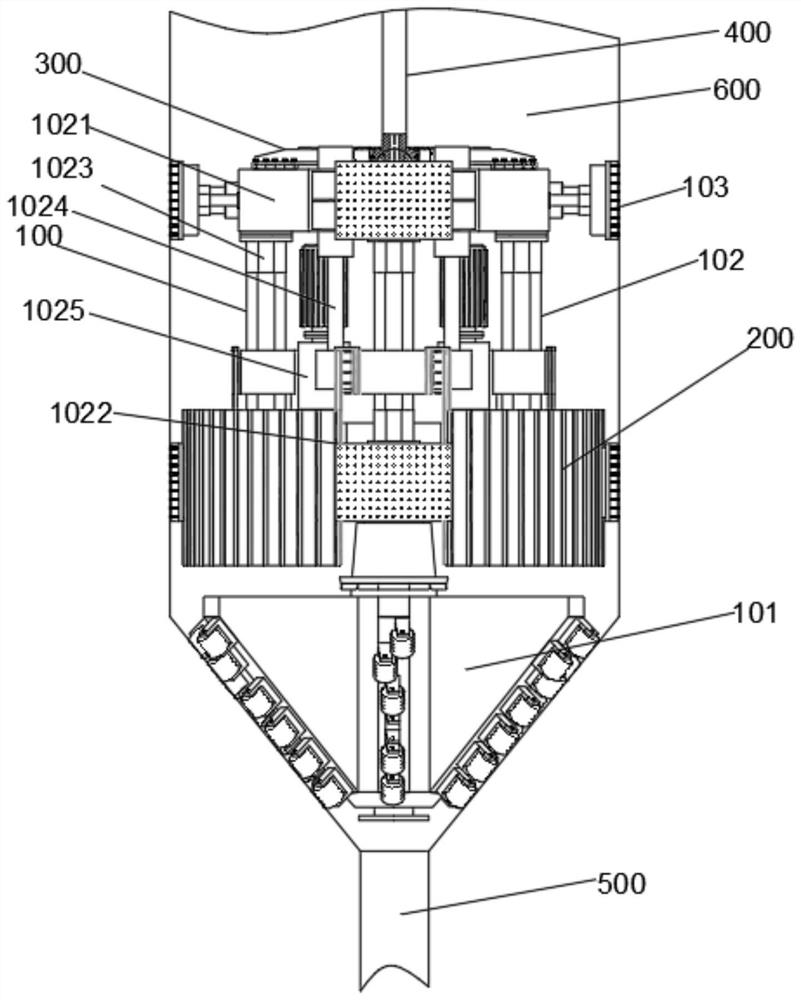

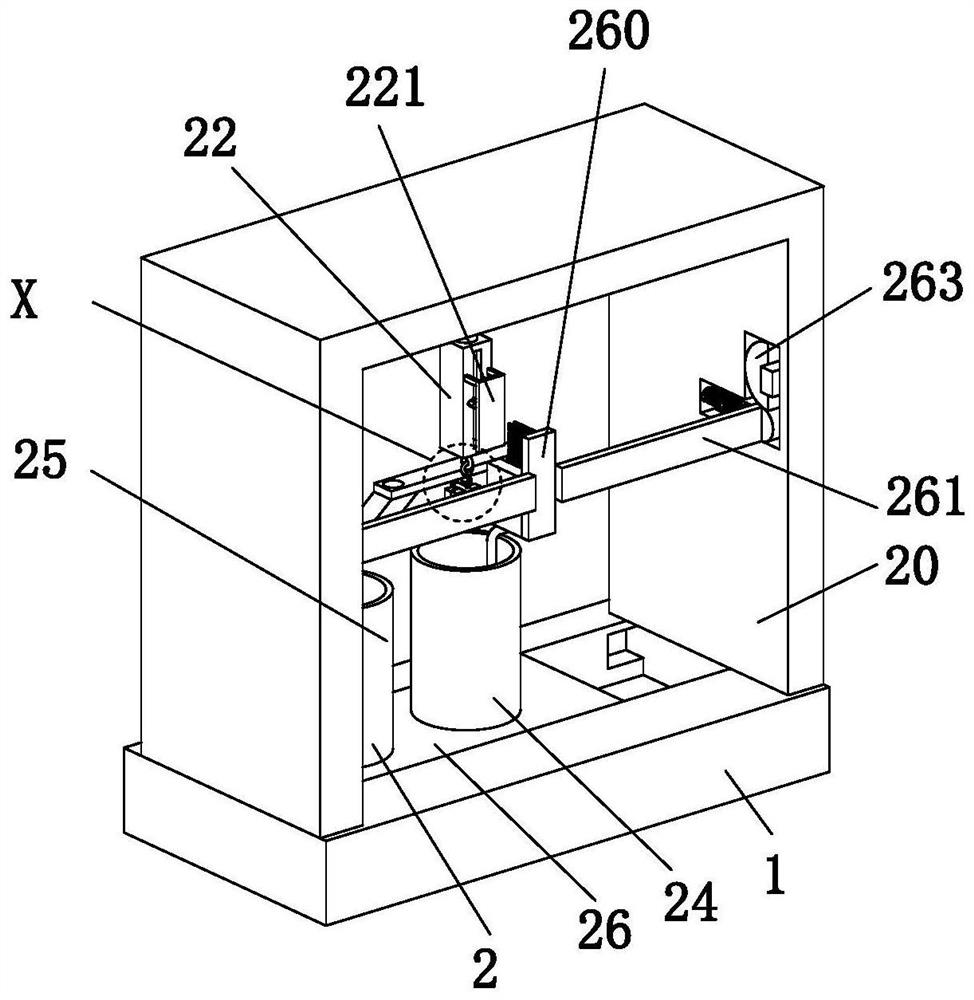

Stable support device of vertical shaft heading machine

The invention provides a stable support device of a vertical shaft heading machine. A fixed center ring is arranged above a cutter head of the heading machine, multiple telescopic devices are annularly arranged on the fixed center ring, the adjacent telescopic devices are connected through connecting devices, and supporting devices are arranged on the telescopic devices. The stable support deviceis compact in structural design, the stability of a stratum during heading of the heading machine is guaranteed greatly, influences of equipment vibration on the stratum are reduced, the safety is improved and the service life of equipment is prolonged during heading of the heading machine, meanwhile, equipment reactive torque is provided to prevent the equipment from rotating under cutting torque, and the stable support device can further temporarily support an unstable stratum and earns time for adoption of other auxiliary construction procedures.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

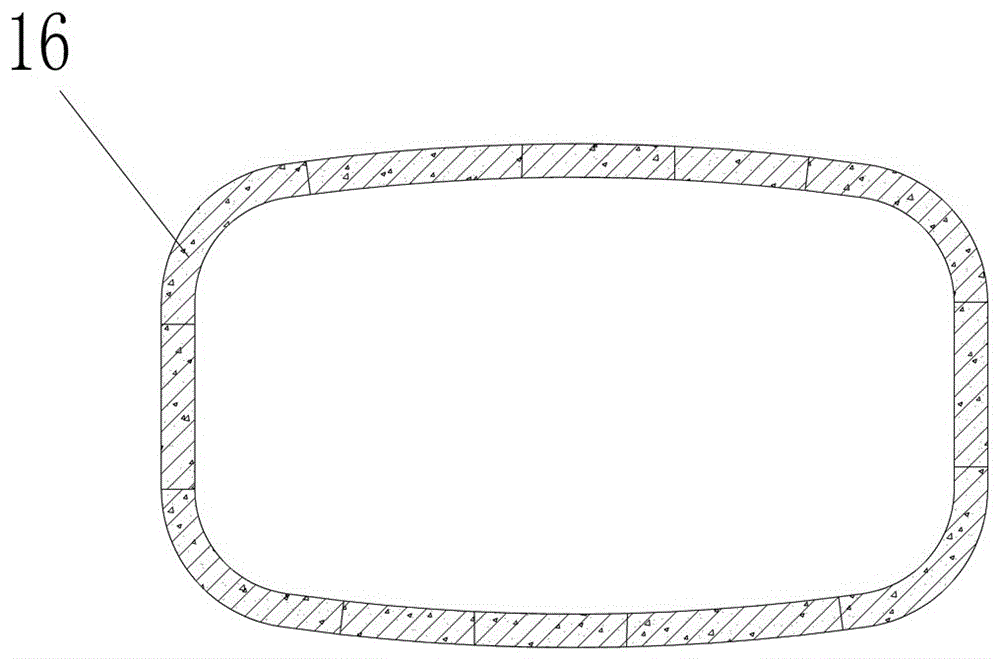

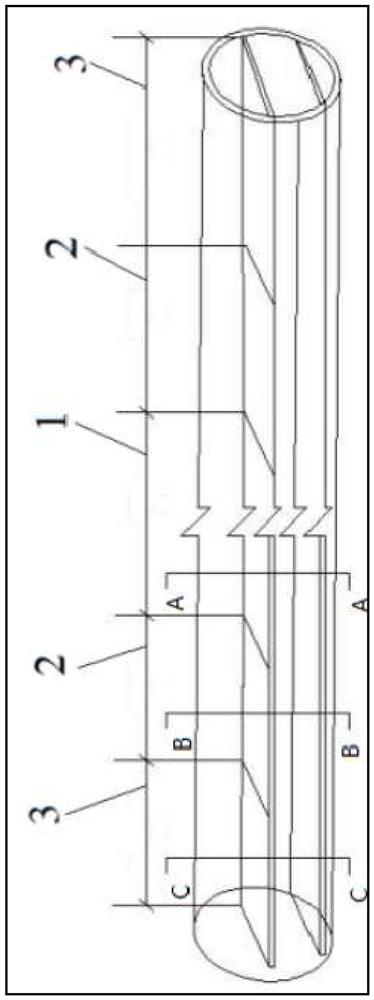

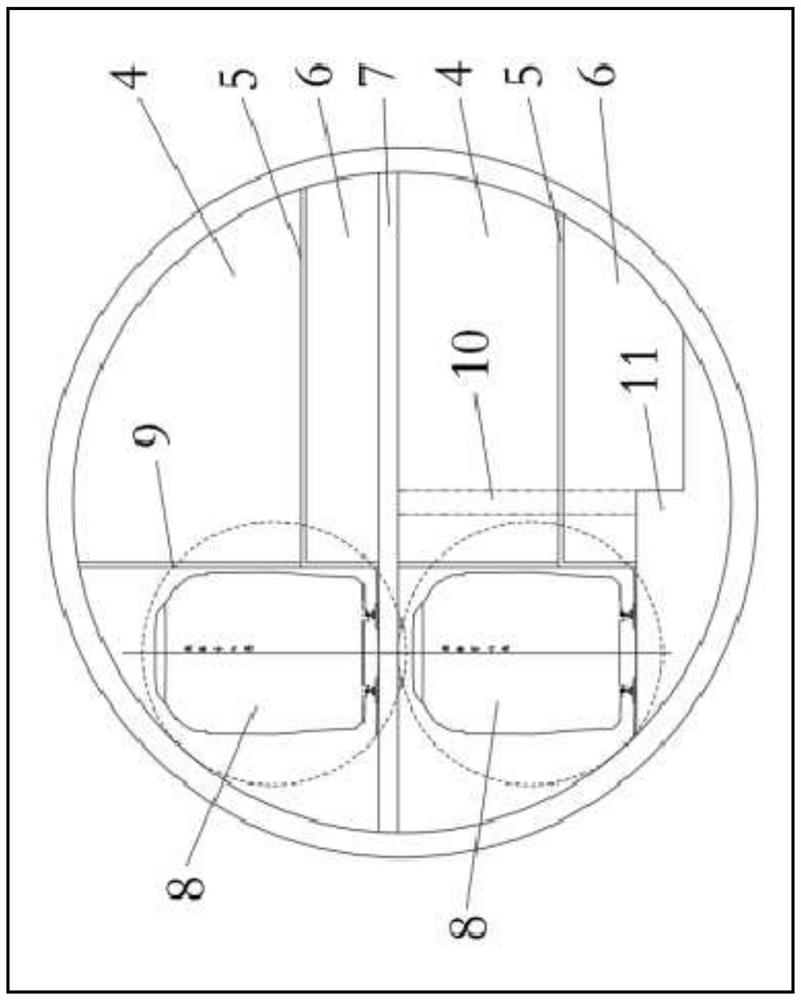

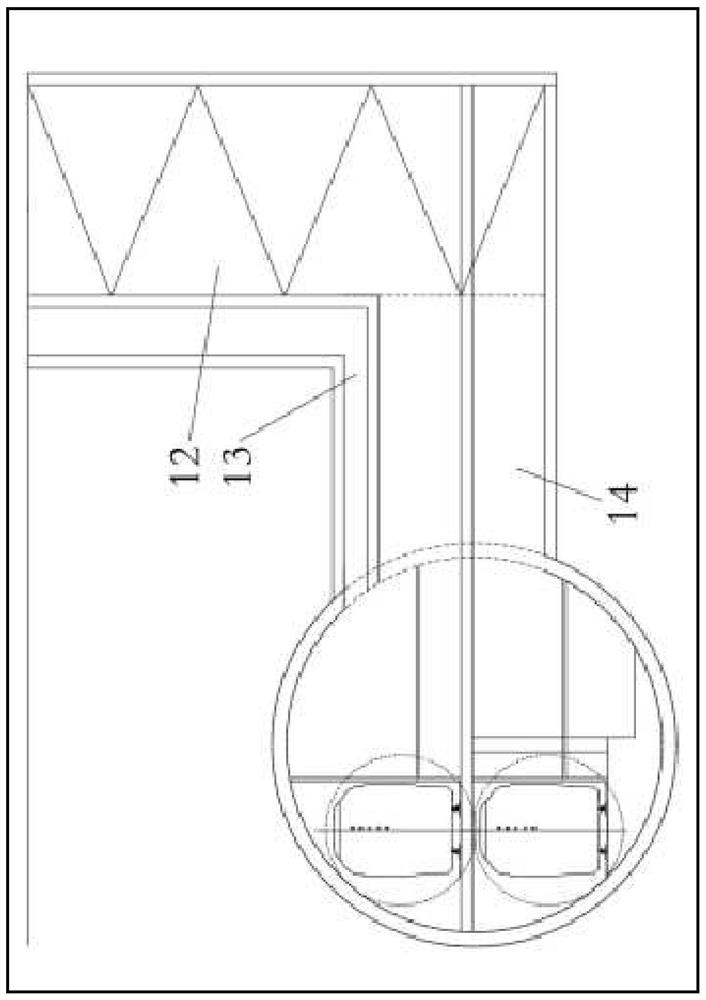

Assemble rectangular ejecting tube section

PendingCN110685712AType of reductionSmall construction impactUnderground chambersTunnel liningWater stopEngineering

The invention discloses an assemble rectangular ejecting tube section. Each rectangular ejecting tube section is composed of two or more than two pieces of assemble prefabricated tube sheets, a convenient and fast joint or a step shear key, a pre-buried water stop steel pnd a sealed water stop rubber strip are arranged on each prefabricated tube sheet, quick positioning and connecting fixing are conducted on the splicing surface of each prefabricated tube sheet through the convenient and fast joint or the step shear key, the pre-buried water stop steel plate is arranged on the outer side of the slicing surface of each prefabricated tube sheet for water stopping, the grouting hole is reversed in the inner side of the splicing surface of each prefabricated tube sheet, the sealed water stop rubber strip is reversed at the splicing surface of each prefabricated tube sheet, and a waterproof system is formed jointly by the pre-buried water stop steel plate, the grouting hole and the sealed water stop rubber strip; and an inter-ring pre-buried water stop steel plate and a sealed water stop rubber strip are arranged between tube sections, and sealing is achieved through ejecting feeding pressure for ejecting. In addition, by being combined with use functions, a wing wall and / or a laminated plate is needed to be arranged in each ejecting tube section to form a space stable structure, atemporary supporting function is achieved during assembling, and the functional requirements of the use state are met.

Owner:北京中岩智泊科技有限公司

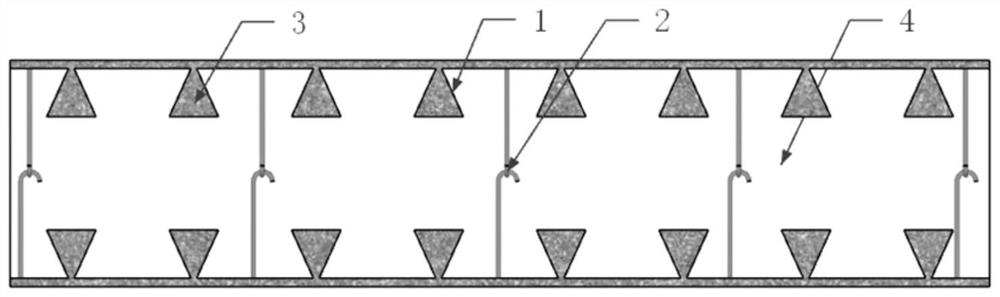

Method for constructing gob-side entry retaining roadside support based on gangue cement-based material

InactiveCN112112672AMaintain stabilityImprove bearing capacityMaterial fill-upMine roof supportsArchitectural engineeringStructural engineering

The invention discloses a method for constructing a gob-side entry retaining roadside support based on a gangue cement-based material, and relates to the technical field of underground gob-side entryretaining roadside supports. The method comprises the following steps: firstly, arranging single props in a gangue transportation roadway, and arranging baffles beside the single props; secondly, starting filling equipment, and sequentially filling a gob with gangue from far to near; thirdly, when a filling body is close to the gob at an entry retaining position, filling and tamping a cementing body; and finally, after a filled wall body is fully solidified and stabilized, recovering a part of or all single props and hinged top beams in a row in the middle of the entry retaining. The method issuitable for a solid filling working surface; gob-side entry retaining is performed by a method of combining the single prop baffles and the tamped cementing body for retaining the roadway; the single props support the hinged top beams or steel beams to achieve a temporary support effect and maintain the stability of the roadway; after the cementing material is tamped, an effect of quickly improving the support strength can be achieved, and the time for waiting for final setting during cementing filling is shortened; and the initial bearing capacity is high, and the entry retaining effect isgood.

Owner:CHINA UNIV OF MINING & TECH

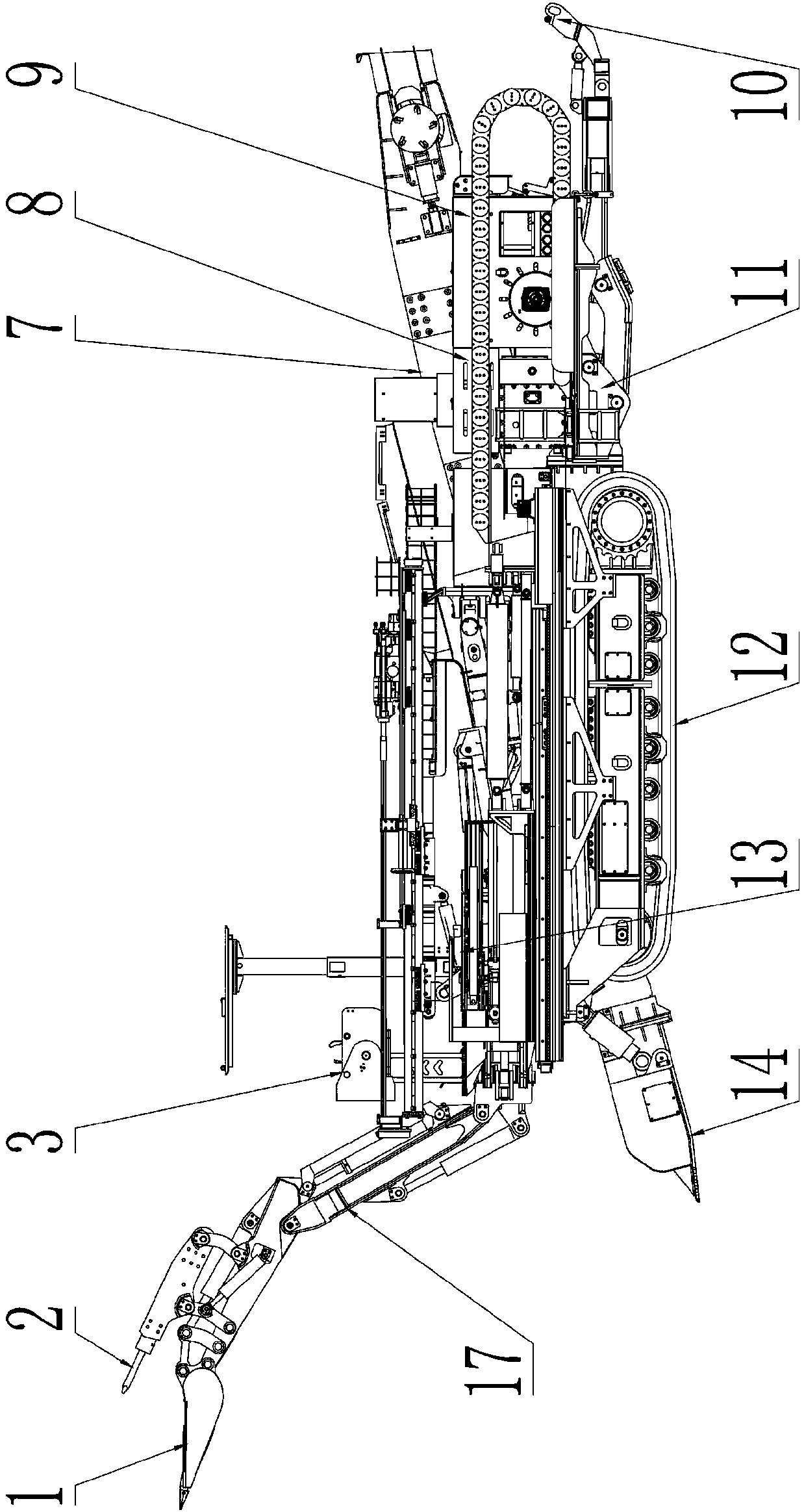

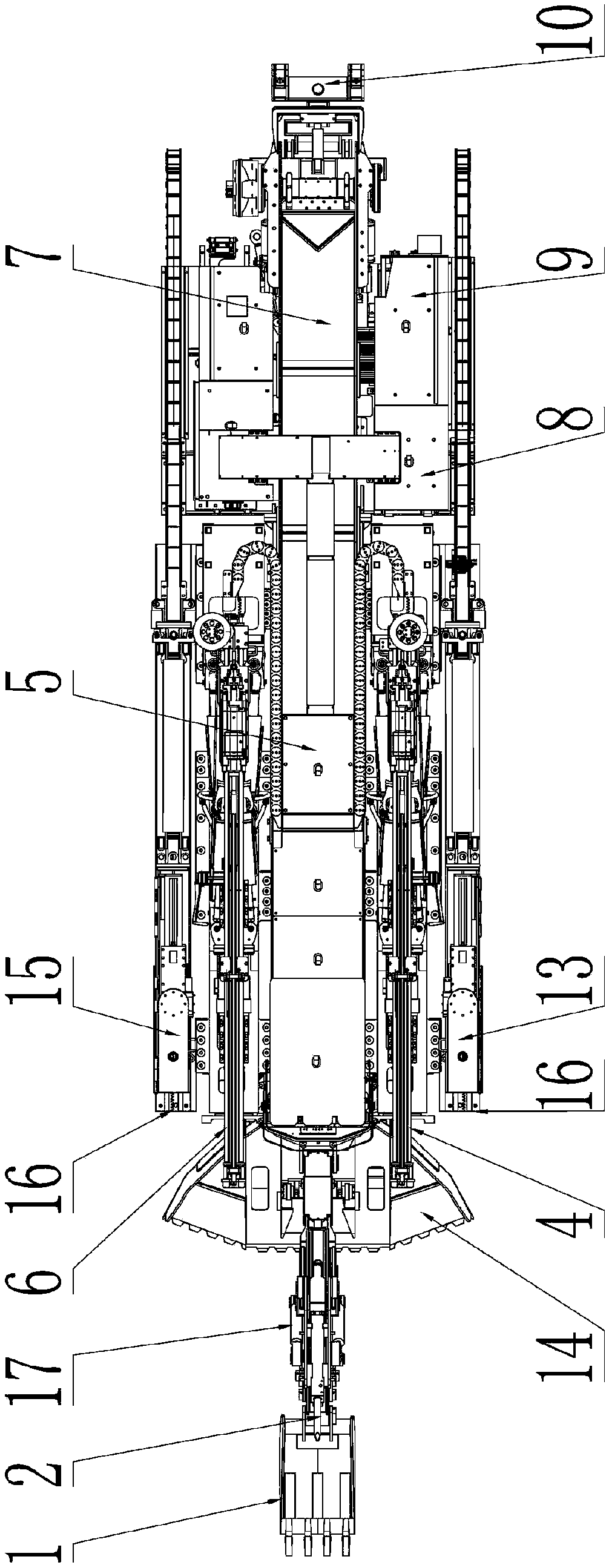

Full-hydraulic intelligent drilling, installing and anchoring all-in-one machine

PendingCN108049877AOperation hasRealize the operationTunnelsAnchoring boltsEngineeringUltimate tensile strength

The invention relates to the technical field of coal mine tunneling machines, in particular to a full-hydraulic intelligent drilling, installing and anchoring all-in-one machine which has the functions of drilling, installing, anchoring and protecting simultaneously. The full-hydraulic intelligent drilling, installing and anchoring all-in-one machine specifically comprises a body, a drilling arm system, a scraper box device, an anchoring and protecting platform, and a conveying system, wherein the drilling arm system, the scraper box device, the anchoring and protecting platform and the conveying system are all arranged on the body. The full-hydraulic intelligent drilling, installing and anchoring all-in-one machine has the functions of drilling, installing, anchoring and protecting simultaneously, and multiple operations can be completed with one machine; the drilling arm system is used for drilling shot holes for achieving the purpose of filling explosives, and crushed rock blocks after blasting are cleared away and collected by the scraper box device and then are received by a second conveyor after being conveyed to the rear side of the body by the conveying system; the anchoring and protecting platform can carry out anchoring and protecting operation in a roadway; when the anchoring and protecting platform works, the scraper box device abuts against the top of the roadway for temporary support, so that safety of operation of workers is improved; and the machine can achieve the functions of drilling, installing, anchoring and protecting simultaneously, so that the laborintensity of workers is lowered on the premise of improving the work efficiency.

Owner:CHINA COAL NO 3 CONSTR GRP +2

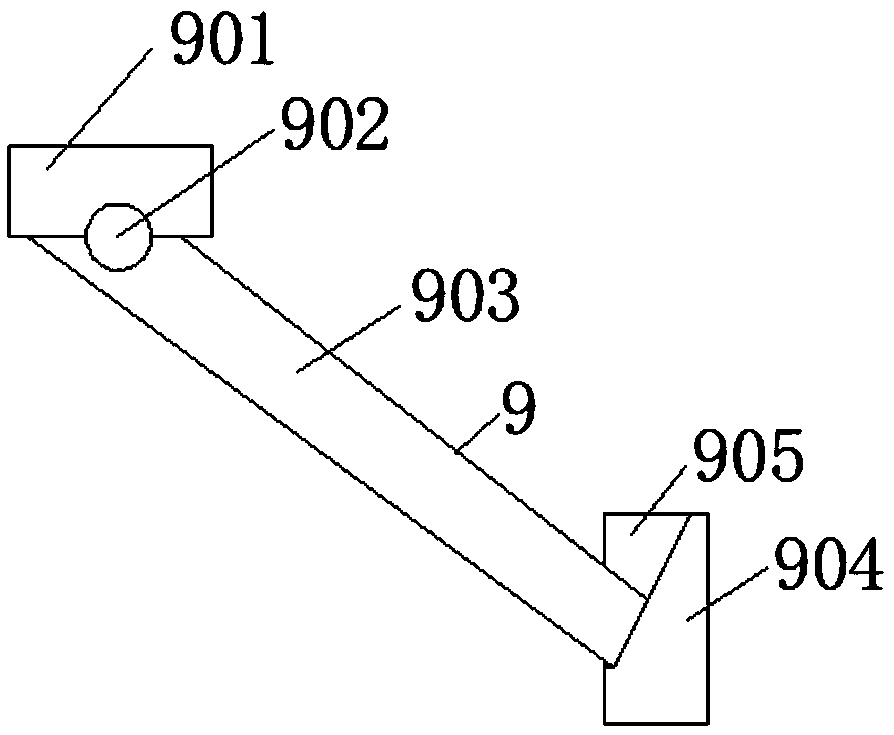

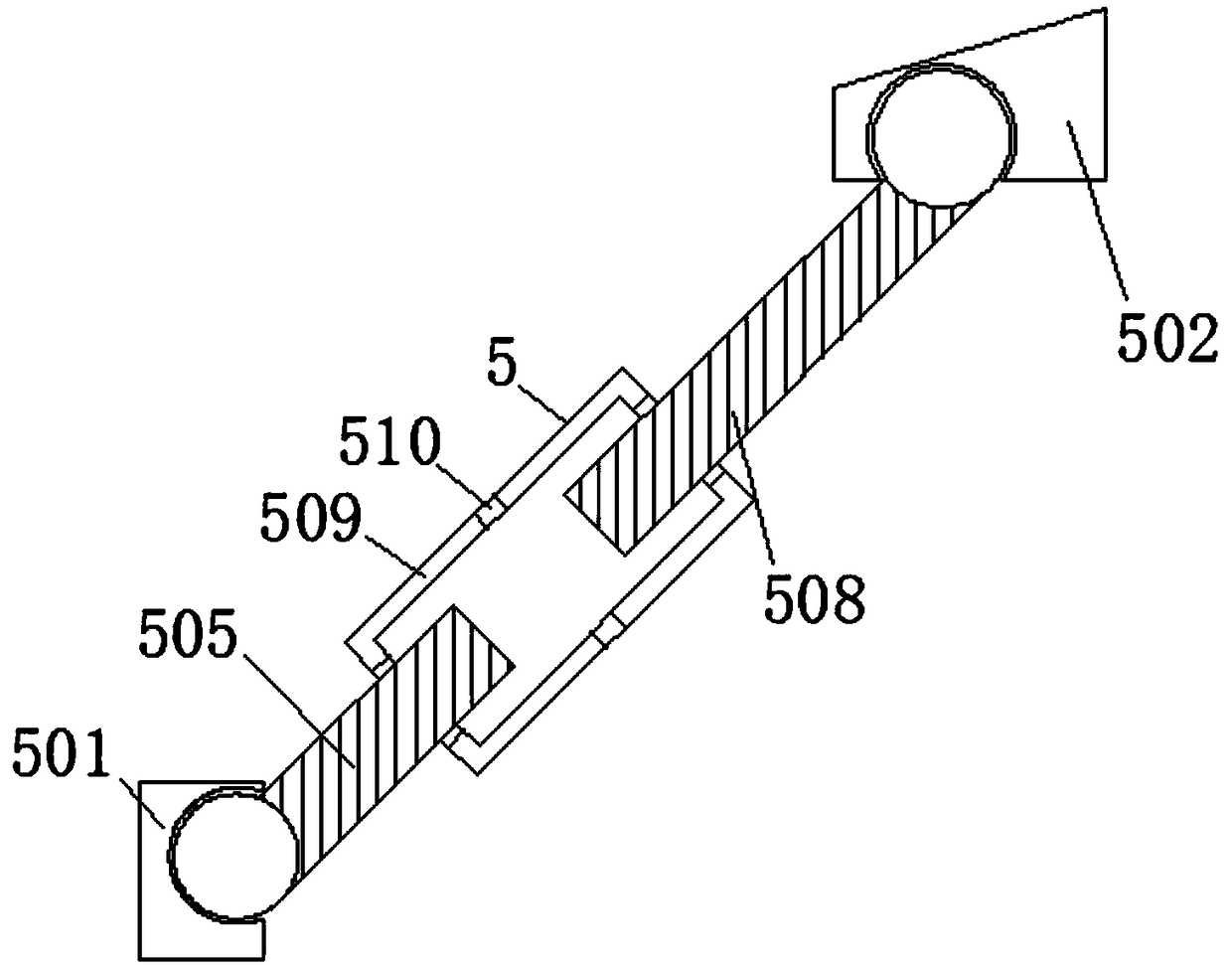

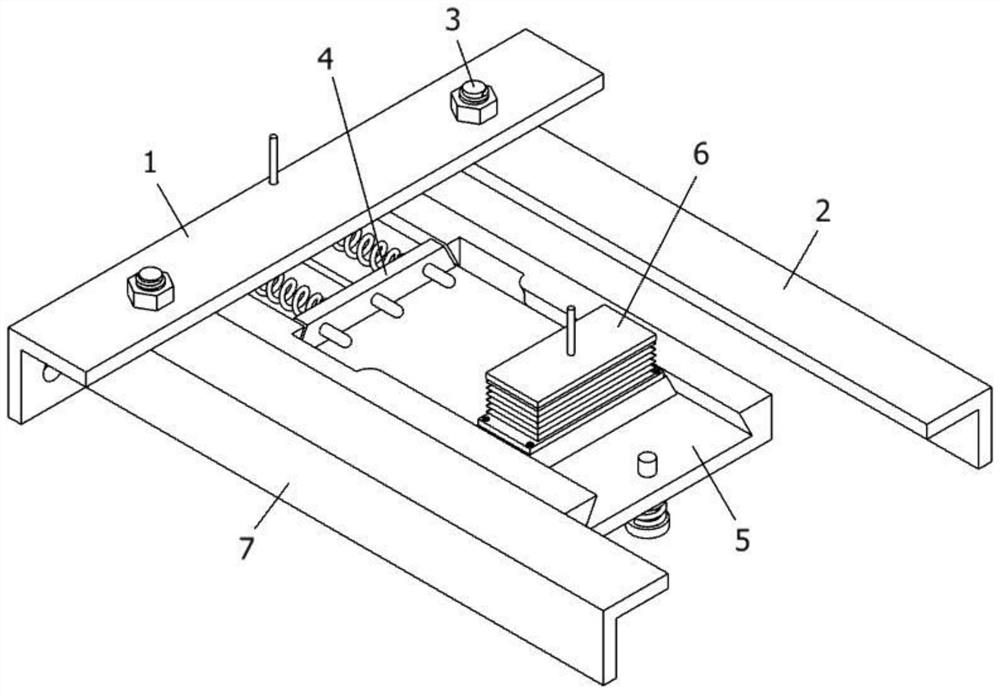

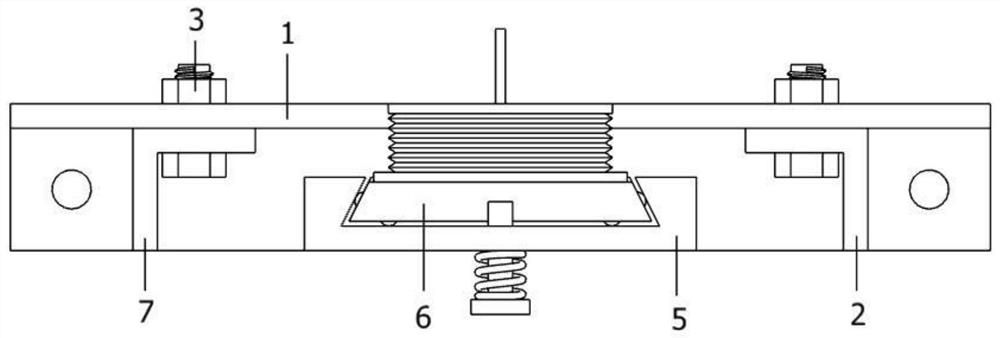

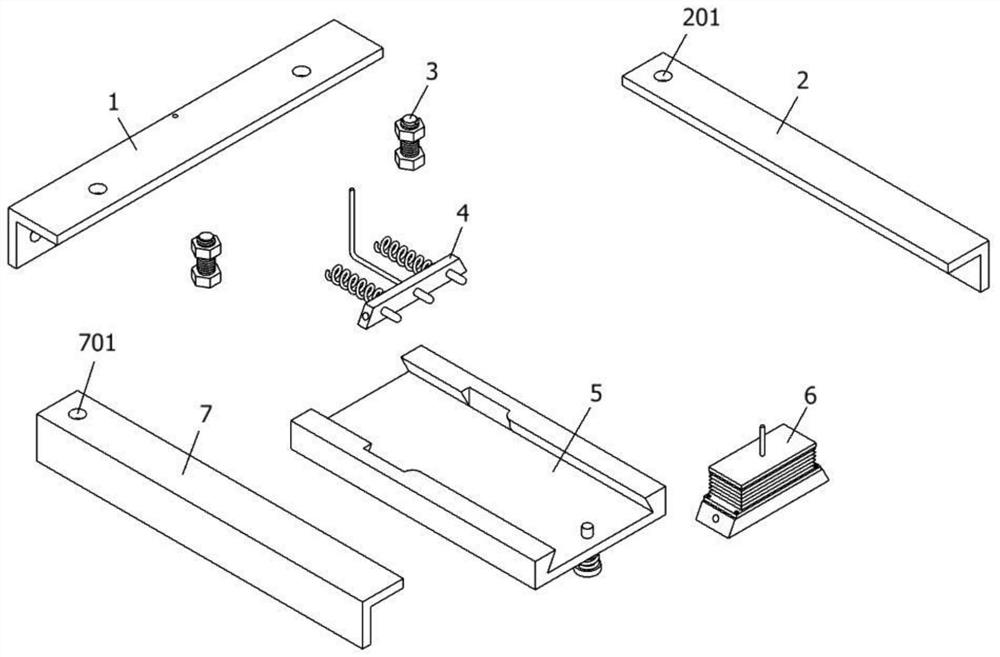

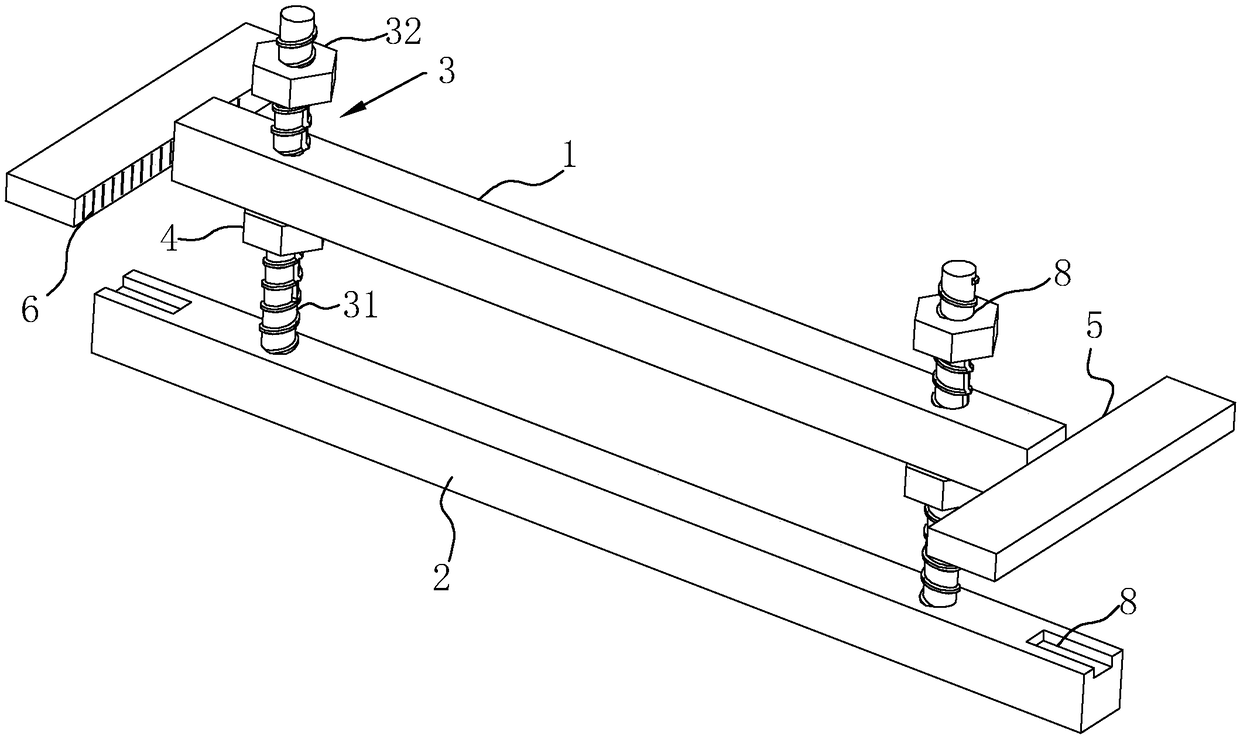

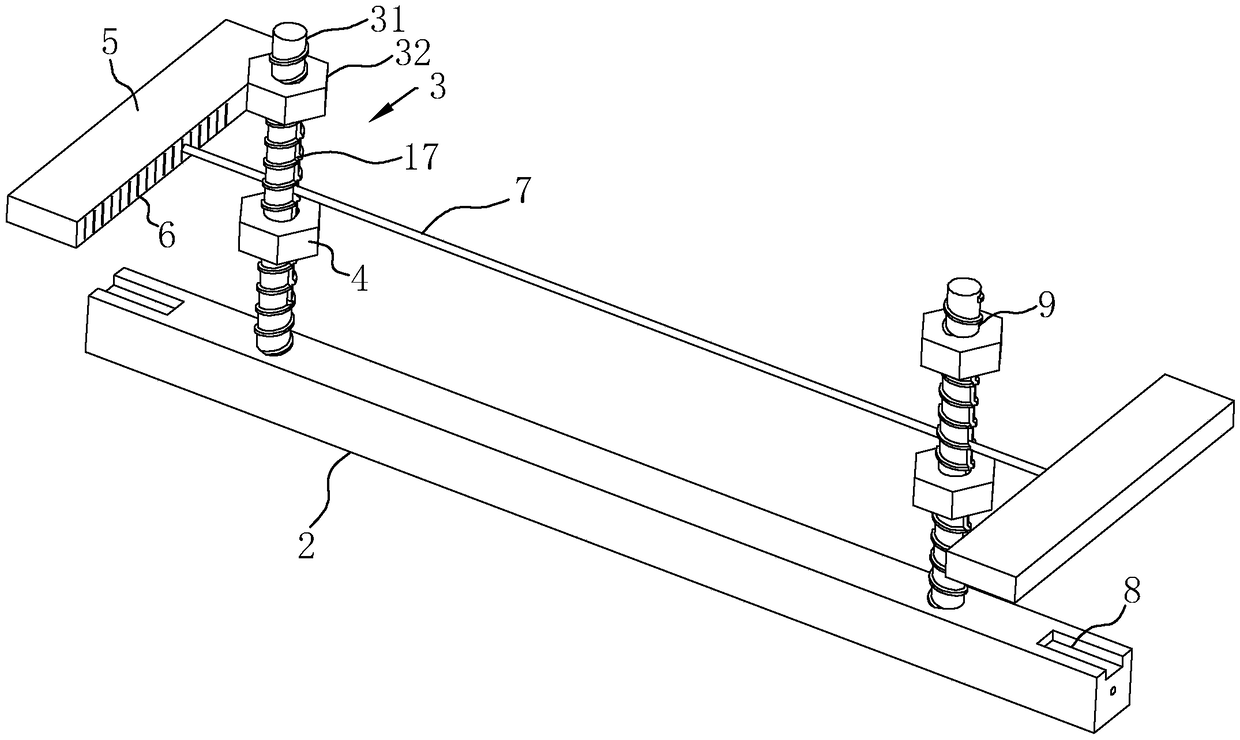

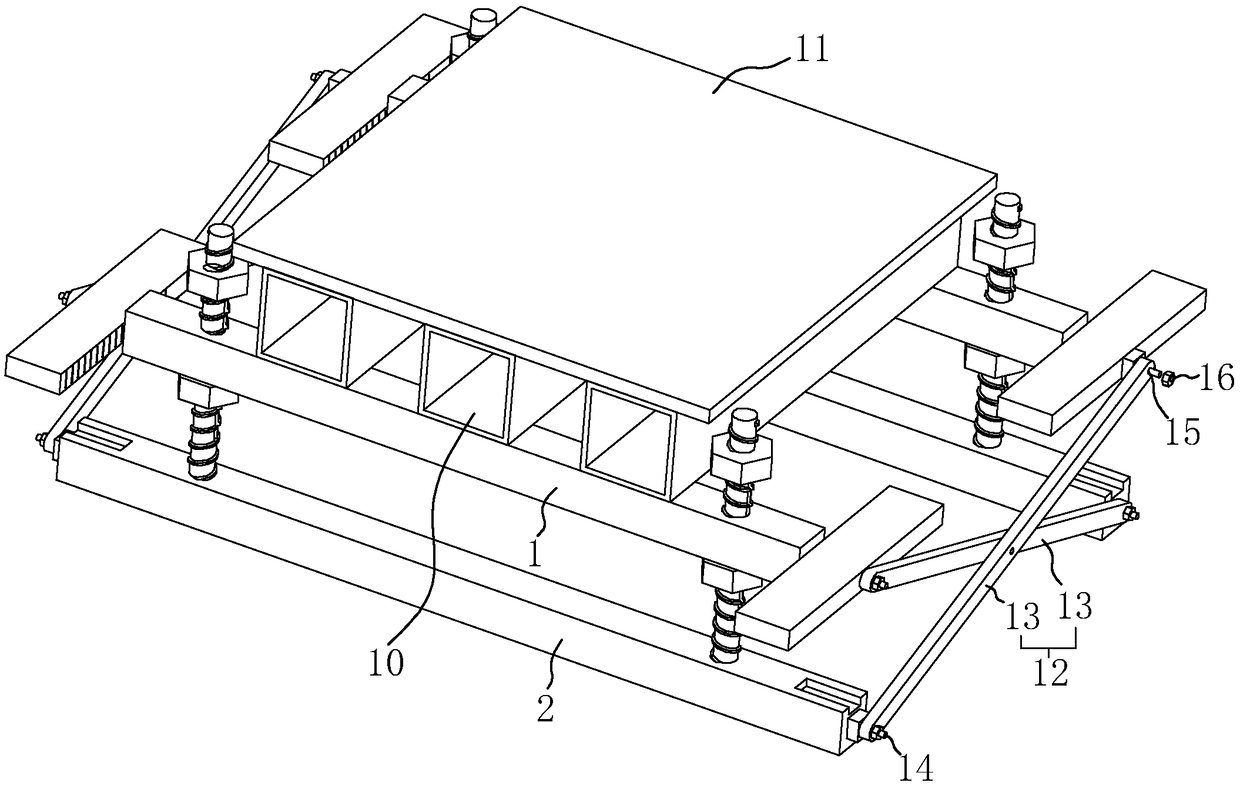

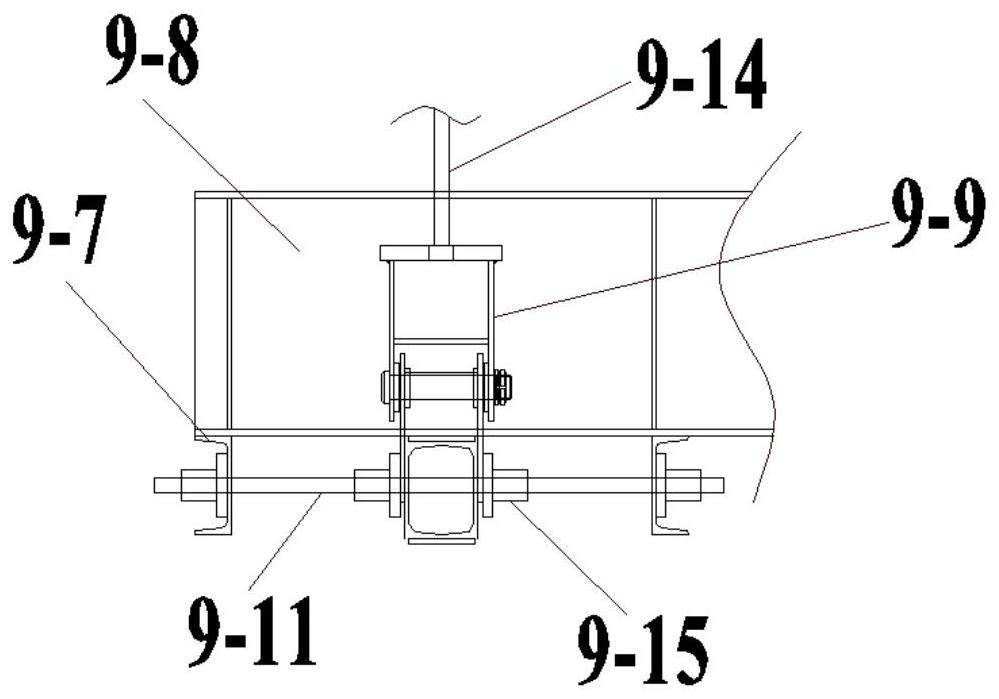

Adjustable steel girder support device and system

ActiveCN109025368AEnsure consistencyReduced Conditioning SituationsShoresSupporting systemSupport system

The invention discloses an adjustable steel girder support device and system; the support device comprises an upper beam, a lower beam, and a support adjusting bolt; the support adjusting bolt is threaded with a support nut; a support bar is rotatably connected on two ends of the upper beam; the distance between the support bar rotary point and the end portion is bigger than that between the support nut and the lower beam top surface; when the support nut height needs to be adjusted, the upper beam is pulled up, the support bars on two ends are rotated, so the long edge of the support bar is in a vertical state and can support the pulled upper beam, and the support nut is rotated and adjusted in positions; in operation, the upper beam does not need to be pulled at all time, so the adjusting operation can be easier and more convenient; the adjustable steel girder support devices can be connected via a shear-fork type structure so as to form the support system, thus ensuring the distanceuniformity between each adjustable steel girder support device; the adjustable steel girder support device is good and stable in support effect.

Owner:广州坚磊建设有限公司

Mechanical rock-breaking drilling process of vertical shaft heading machine in broken stratum

PendingCN113266358AProtect the bodyImprove temporary support capacityDirectional drillingShaft sinkingGeotechnical engineeringDrill bit

The invention discloses a mechanical rock-breaking drilling process of a vertical shaft heading machine in a broken stratum. The mechanical rock-breaking drilling process of the vertical shaft heading machine in the broken stratum comprises the following steps: step A, preparation work: connecting a raise-drilling rod with the vertical shaft heading machine; step B, starting of drilling: pushing a gear reduction box to move downwards by a telescopic oil cylinder, then enabling a drill bit to move downwards, and enabling a quarter shield to synchronously move downwards along with a sliding ring on the gear reduction box to temporarily support a well side; step C, circulating drilling: matching the raise-drilling rod with a shoe plate, and circulating the step B; step D, supporting the well side by workers on a hanging scaffold; and step E, completion of drilling: completing drilling by circulating the steps B-D. According to the invention, the vertical shaft heading machine is lifted by using the raise-drilling rod, so that the vertical stress of the shoe plate is canceled, and the shoe plate only bears the reaction torque driven by the rotation of the drill bit, so that the supporting force of the shoe plate on a broken well wall is reduced to the minimum, and the reaction torque can also be provided in the broken stratum.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Combined type structure with recycling effect for underground engineering

ActiveCN106337689AAct as a temporary supportEasy to installArtificial islandsUnderground chambersEngineeringSteel structures

The invention discloses a combined type structure with a recycling effect for underground engineering. The combined type structure comprises a prefabricated part, wherein the prefabricated part comprises a plurality of steel structural members and concrete structural members; each steel structural member is arranged at the inner side of the corresponding concrete structural member; each steel structural member comprises a standard joint group and a movable joint, each standard joint group comprises an upper standard joint and a lower standard joint which are connected by the corresponding movable joint, and the width of each movable joint is smaller than the width of each of corresponding upper standard joint and lower standard joint. The combined type structure has the advantage that after each steel structural member is detached, the corresponding steel structural member is arranged on the other concrete structural member to form a new prefabricated part, so that the recycling effect is realized, and the cost is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

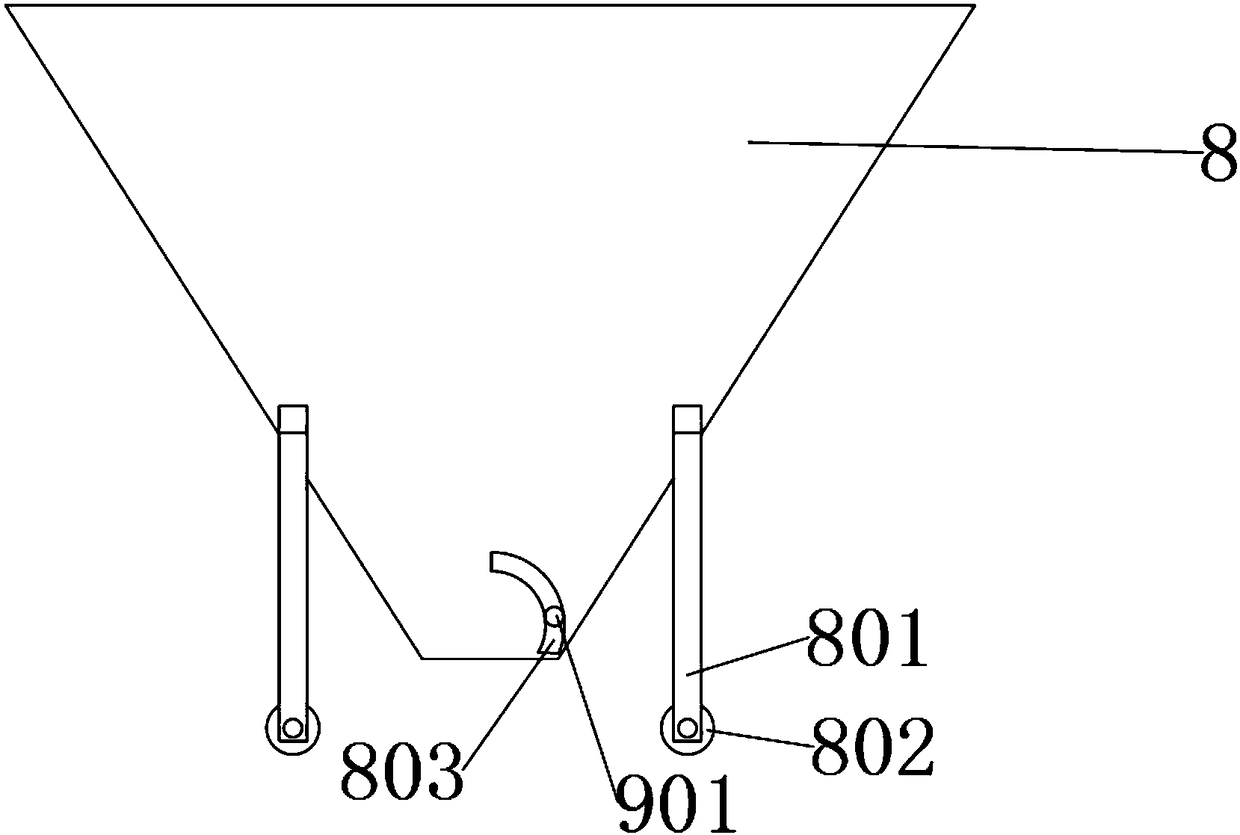

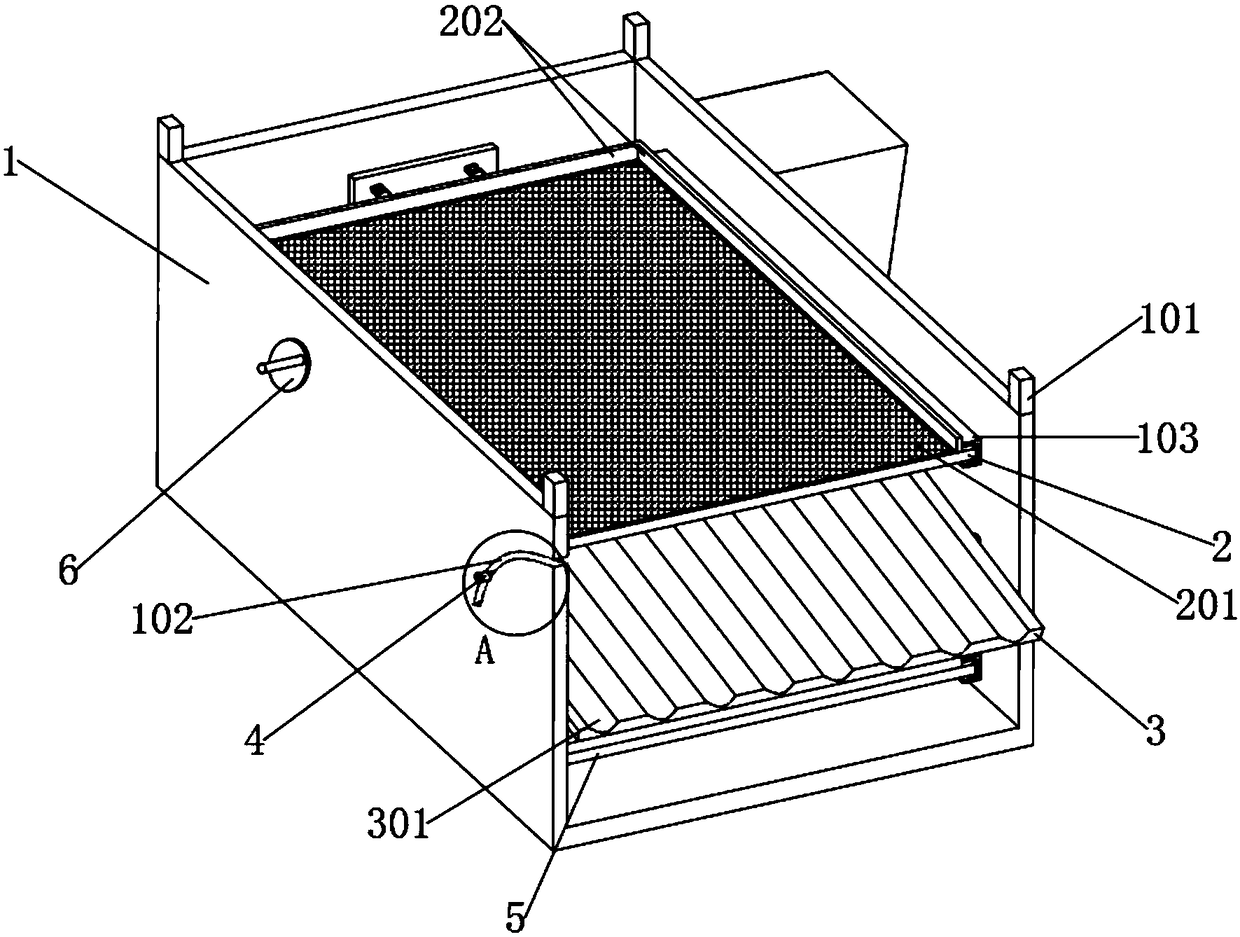

Vibrating screen equipment for screening building sand

The invention provides vibrating screen equipment for screening building sand. The vibrating screen equipment comprises an arc-shaped groove, a top plate, a hand piece, a sand baffling plate and clamping teeth, wherein a screening body is of a rectangular hollow structure; a screen mesh is mounted in the screening body; a baffle plate is mounted above the screening body in a welding manner; a sandreceiving plate is connected with the internal side edge of a main body through an auxiliary connecting piece; and the sand baffling plate is mounted above the sand receiving plate in a welding manner. The material is added in a sand storage cabin manually; and the hand piece is rotated downwards manually, so that the front end of the top plate jacks up the sand baffling plate; through rotating the hand piece by different angles manually, the front end of the top plate is clamped in the clamping teeth below the sand baffling plate to enable the sand baffling plate to ascend to different heights, so that different amounts of material flow out; and when the materials flow out, the sand storage cabin is pushed manually to move along the upper part of the main body, so that the material flowsout of different positions.

Owner:江苏恒源建设有限公司

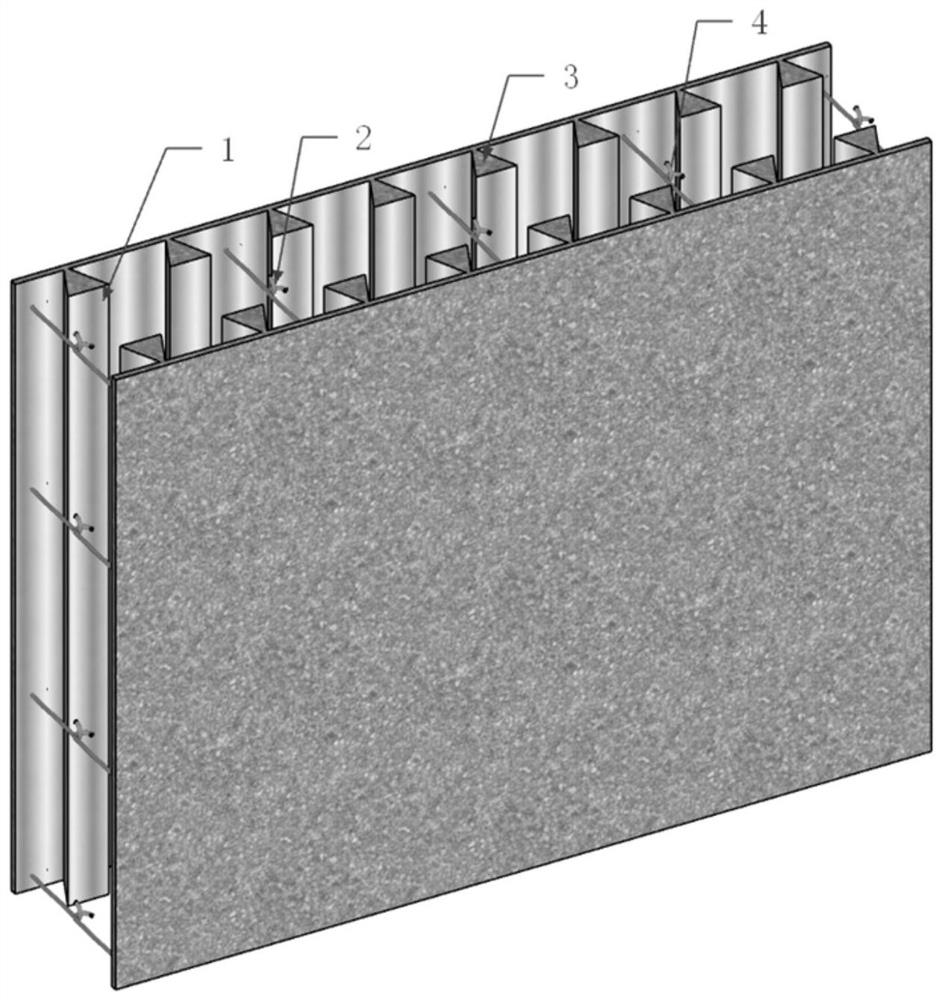

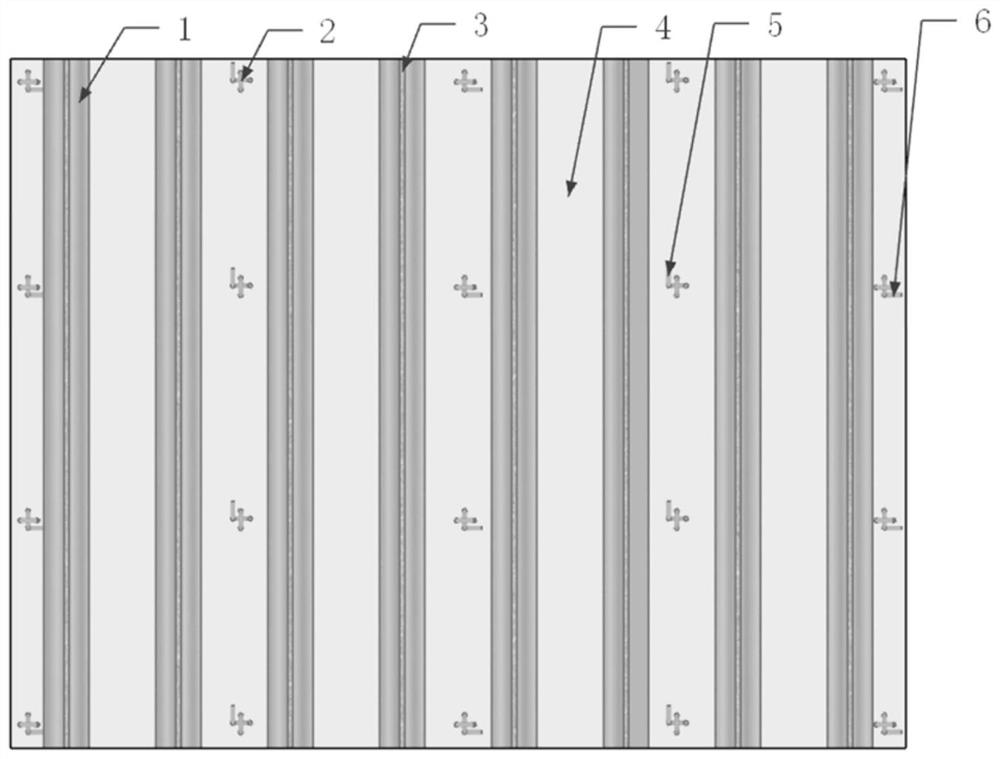

UHPC (Ultra High Performance Concrete)-necking type profiled steel sheet composite template composite shear wall

PendingCN114293688APrevents out-of-plane elastic bucklingWork together wellWallsNeckingTransverse shear

The invention discloses a UHPC (Ultra High Performance Concrete)-necking type profiled steel sheet composite template combined shear wall. The shear wall comprises two necking type profiled steel sheets, the two necking type profiled steel sheets are oppositely distributed, UHPC layers are formed on the outer sides of the two necking type profiled steel sheets in a pouring mode, J-shaped hooks are arranged on the two necking type profiled steel sheets, one ends of the J-shaped hooks are located in the UHPC layers, longitudinal shear keys and transverse shear keys are fixed to the ends of the J-shaped hooks, the other ends of the J-shaped hooks penetrate through the necking type profiled steel sheets, and the longitudinal shear keys and the transverse shear keys are fixed to the UHPC layers. J-shaped hooks are arranged on the two necking-down type profiled steel sheets, the J-shaped hooks on the two necking-down type profiled steel sheets are in one-to-one correspondence, the J-shaped hooks on one necking-down type profiled steel sheet are connected with the corresponding J-shaped hooks on the other necking-down type profiled steel sheet in an opposite pulling mode, and concrete is poured between the two necking-down type profiled steel sheets. And under the action of a horizontal load, the shear failure is not easy to occur.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

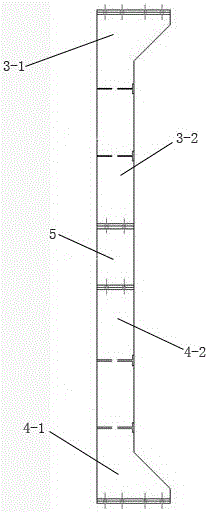

Underground excavation construction method of assembling corrugated steel plate underground comprehensive pipe corridor

The invention relates to an underground excavation construction method of an assembling corrugated steel plate underground comprehensive pipe corridor, and belongs to the technical field of municipalunderground facility construction methods. The underground excavation construction method of the assembling corrugated steel plate underground comprehensive pipe corridor is used for carrying out underground excavation construction on the underground pipe corridor, and has the technical scheme that the method comprises the steps of perpendicularly excavating a vertical shaft, placing a vertical shaft helical bellow in the vertical shaft, connecting one side of the vertical shaft helical bellow to a helical bellow tee, excavating a horizontal pipe corridor along the horizontal direction of thehelical bellow tee, tunneling and assembling corrugated steel plates at the same time so as to form the horizontal pipe corridor, then grouting through a grouting port, and forming an integrated structure through grout and the assembling corrugated steel plate of the horizontal pipe corridor. The underground excavation construction method of the assembling corrugated steel plate underground comprehensive pipe corridor provided by the invention is the pioneer for carrying out underground comprehensive pipe corridor construction by using assembling corrugated steel plate materials, so that the problem that a municipal underground comprehensive pipe corridor needs to be open-excavated is solved; and compared with a traditional concrete-structure comprehensive pipe corridor, the steps of initially lining and temporary supporting are saved, so that the method is simple, convenient and fast, the construction speed is greatly improved, the construction cost is saved, and the method has a great popularization and application value in municipal construction engineering.

Owner:冀中能源井陉矿业集团元氏矿业有限公司

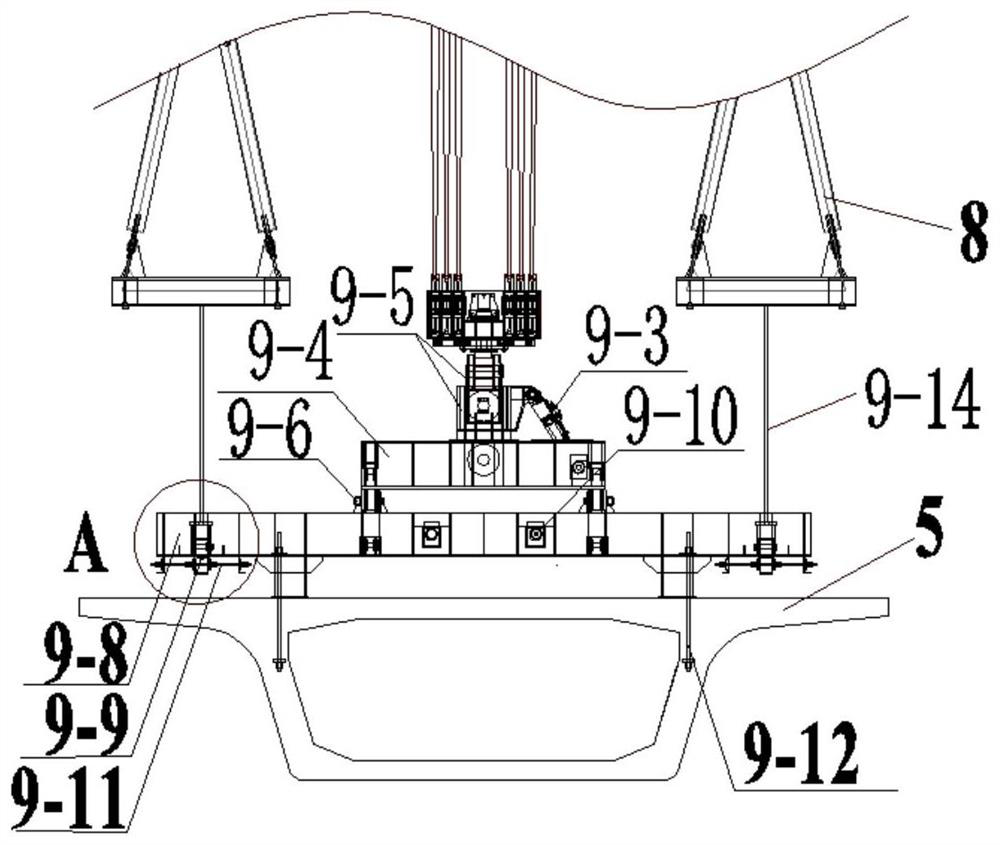

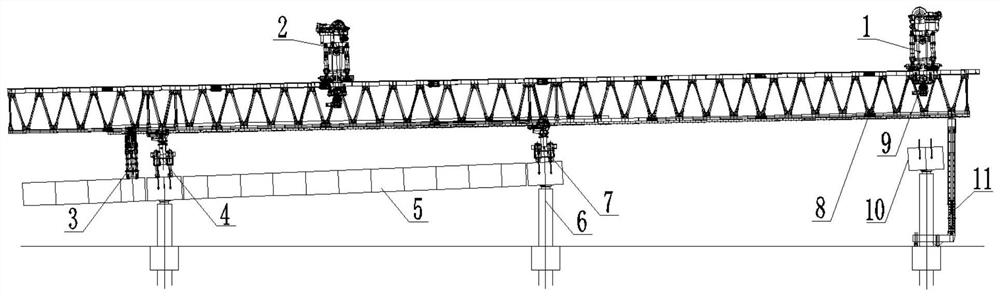

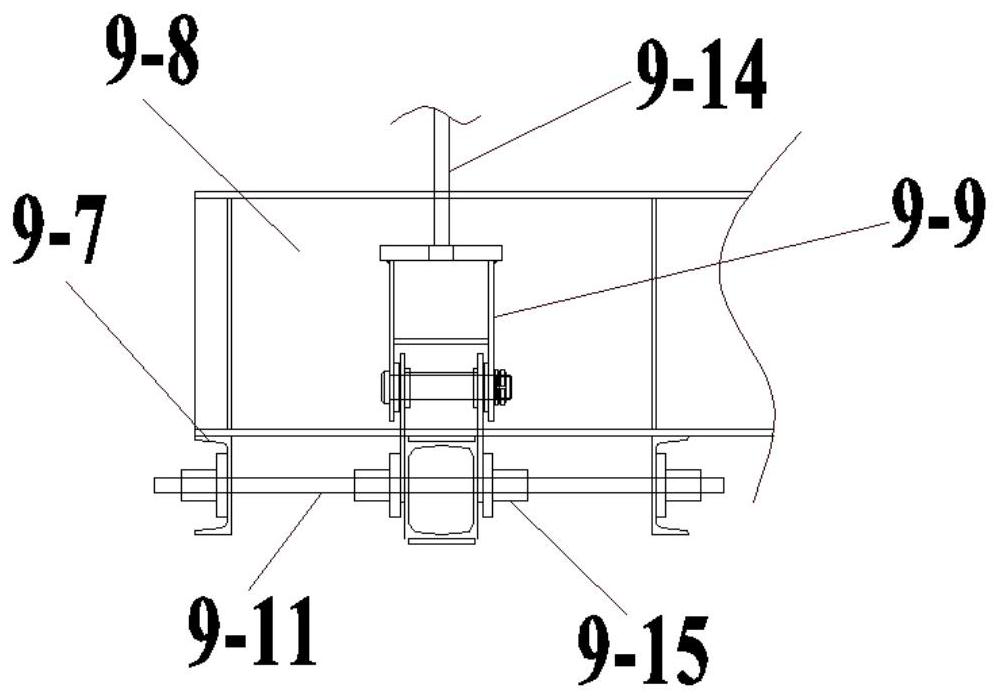

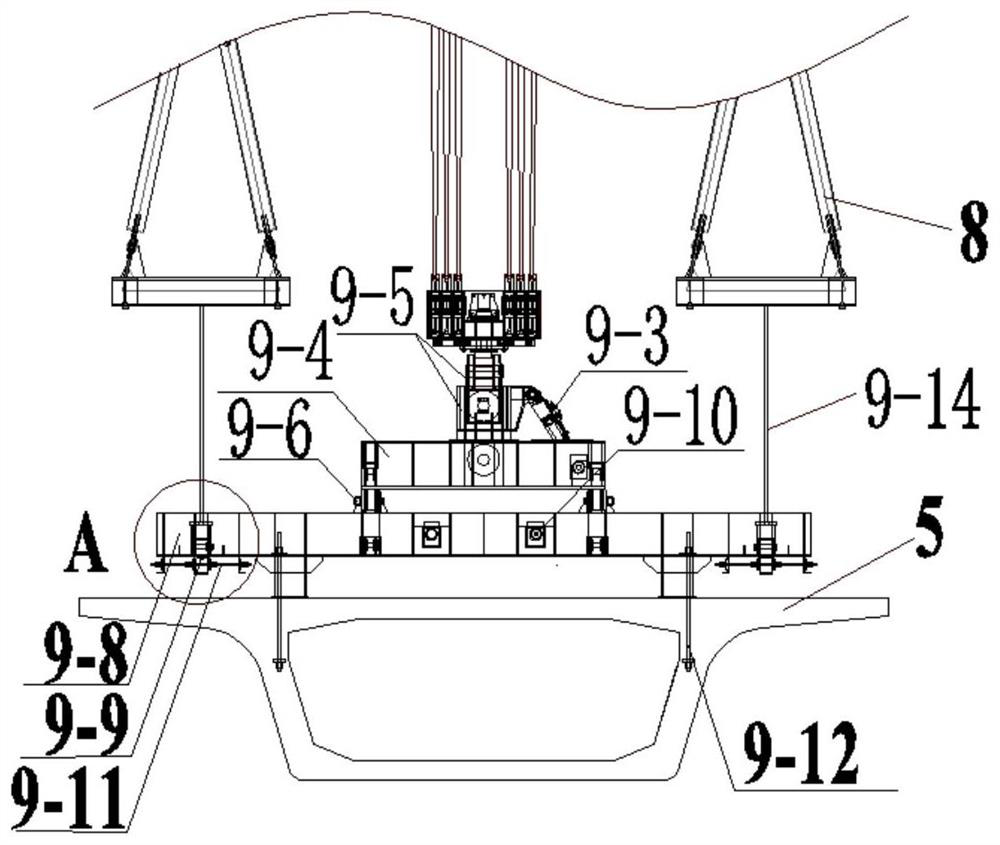

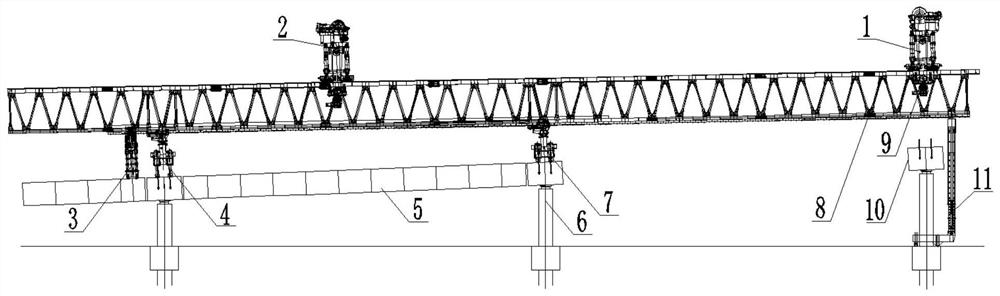

Segment assembling integrated bridge girder erection machine and construction method thereof

ActiveCN112195798AAvoid frequent disassemblyAvoid replacementBridge erection/assemblyBridge materialsArchitectural engineeringStructural engineering

The invention discloses a segment assembling integrated bridge girder erection machine and a construction method thereof. The segment assembling integrated bridge girder erection machine comprises a main girder overhung in the erection direction, a hanging connecting mechanism movably arranged on the main girder and a hanger detachably connected with the hanging connecting mechanism. The hanger comprises a cross beam and a pair of short beams arranged below the cross beam, the short beams are perpendicular to the cross beam and are close to the two ends of the cross beam respectively, and vertical segmental beam hanging points are arranged at the positions, close to the ends, of the short beams in a penetrating mode respectively. pier stud hanging points are arranged on the lower bottom surface of the cross beam. The machine is provided with a universal hanger, pier top blocks, segmental beams and pier studs can be hoisted, frequent disassembly and replacement of a hanger in the construction process are avoided, and the construction efficiency is improved.

Owner:CCCC SECOND HARBOR ENG +1

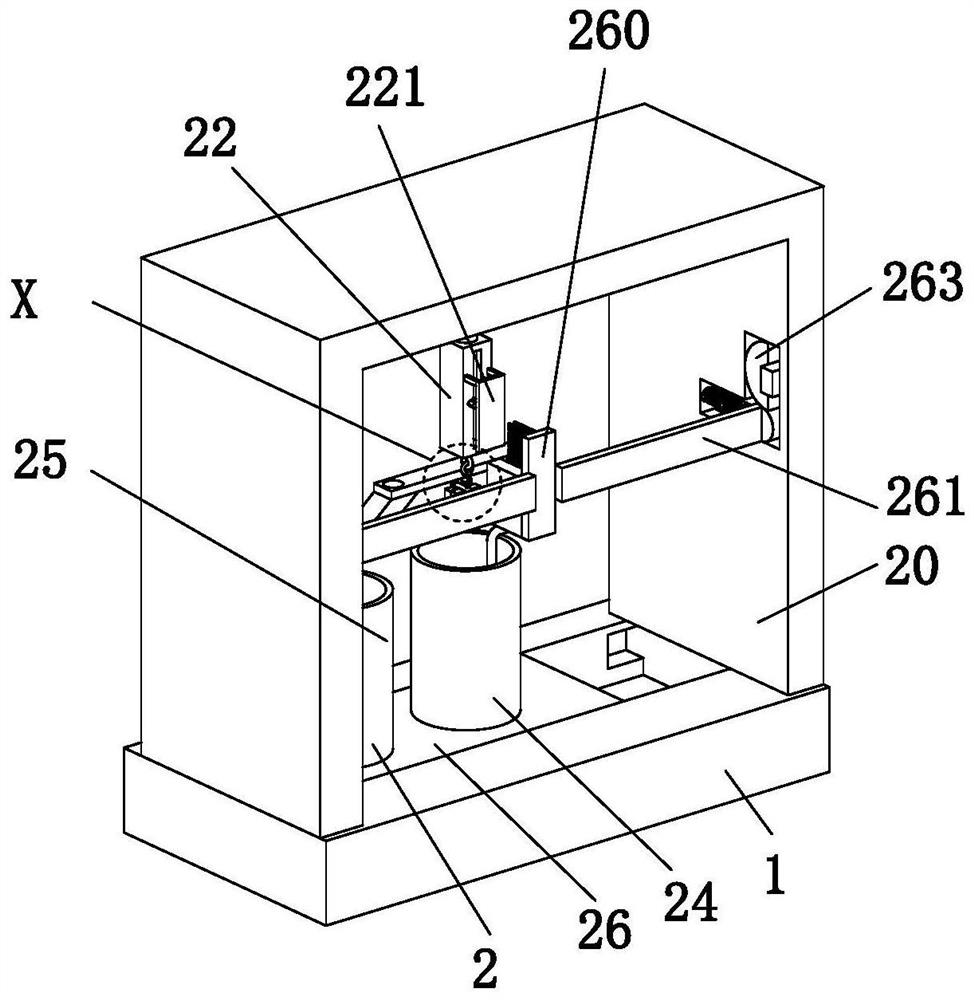

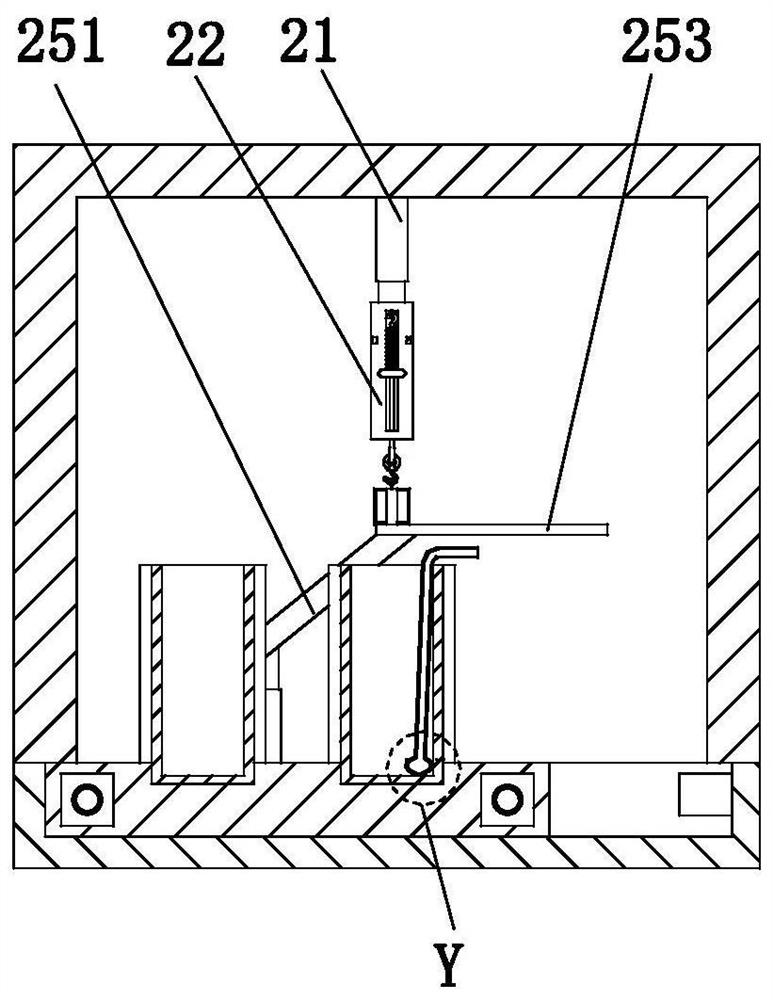

Physics teaching experiment display system

ActiveCN111879660AEnables triple density measurementFunctional DiversificationTeaching apparatusSpecific gravity measurementLiquid densityEngineering

The invention relates to a physics teaching experiment display system, which comprises a base station and an experiment mechanism, and is characterized in that the base station is arranged on an existing working tabletop in a sliding fit mode, and the experiment mechanism is arranged at the upper end of the base station. According to the invention, the design concept of a multi-density measurementstructure is adopted for physics teaching experiment display; The whole arranged experimental mechanism has the function of measuring the triple density of solid, liquid and gas under the cooperationof other density measuring structures, so that the functions of the whole device are diversified, and the practicability and the display performance of the whole device are improved; the sponge stripand the sponge block can absorb and remove liquid carried by the elastic dynamometer and residual liquid on the surface of an object by means of the shape characteristics of the sponge strip and thesponge block, so that the probability that the density measurement result is influenced by additional factors is reduced to the maximum extent, and the accuracy of object or liquid density measurementis improved.

Owner:东台汇赢创融科技发展有限公司

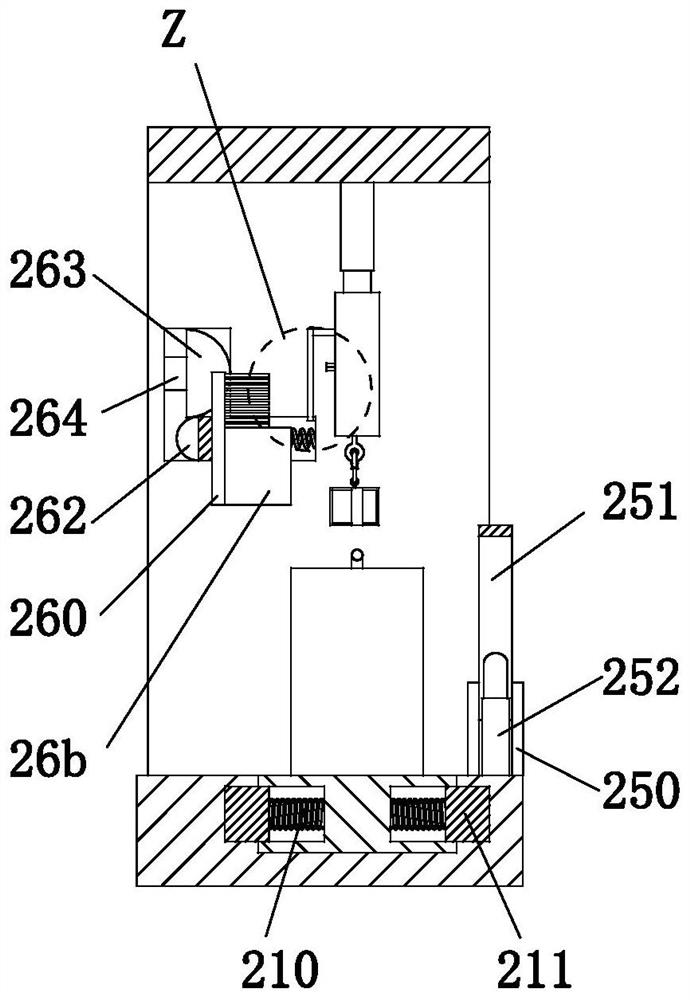

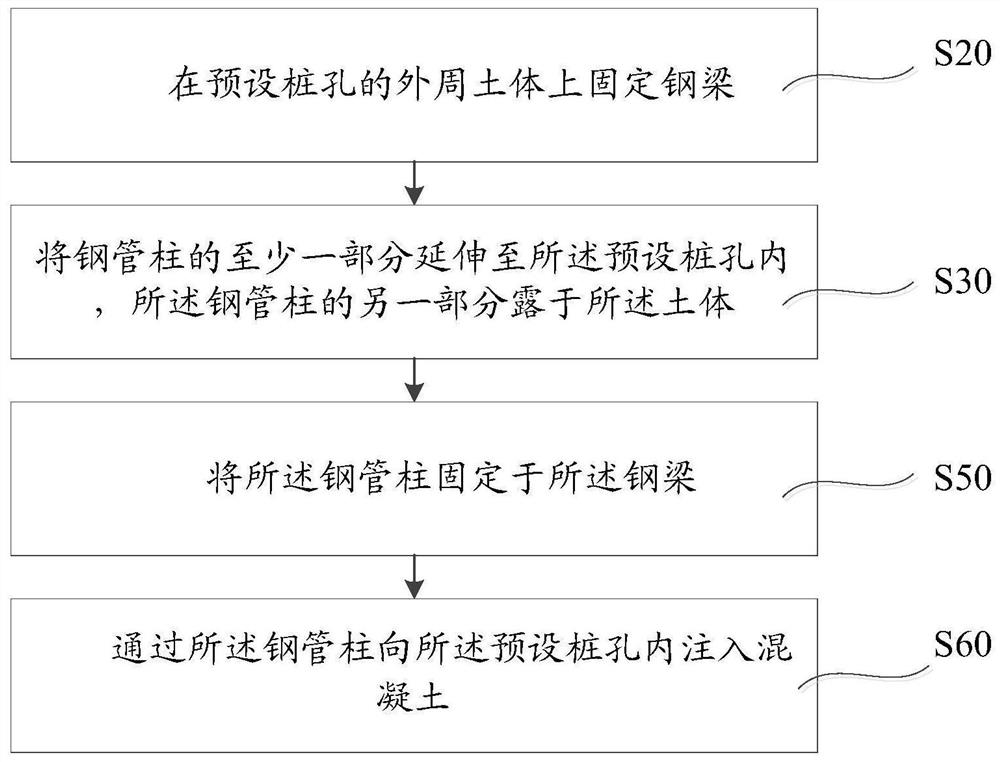

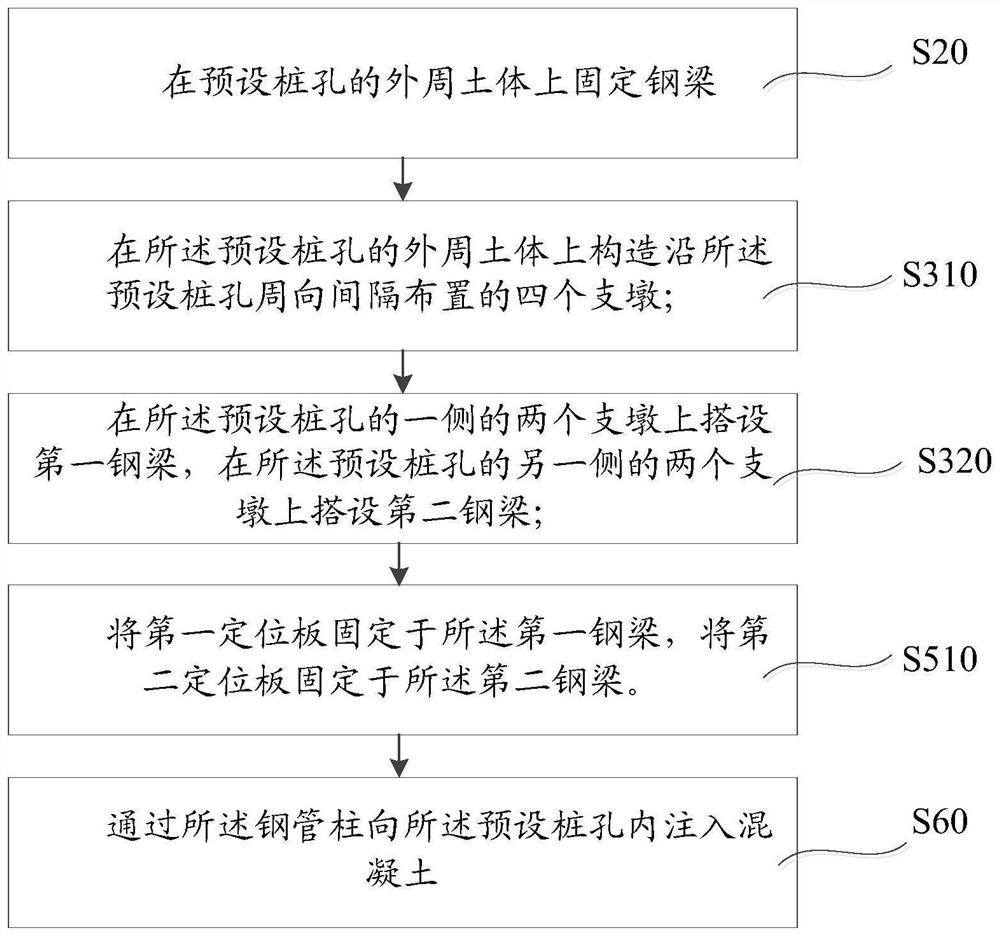

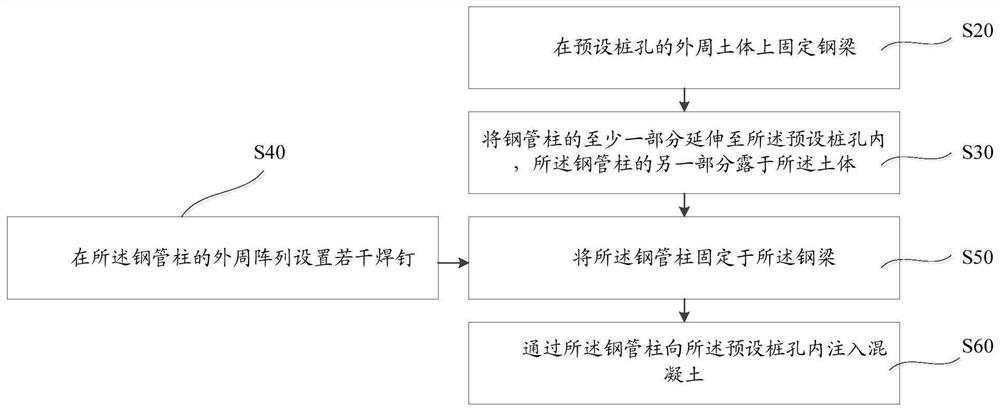

Pile foundation construction method and pier construction method

PendingCN113718814AThe pier foundation is stable and reliableAct as a temporary supportBridge structural detailsBridge erection/assemblyArchitectural engineeringPipe

The invention discloses a pile foundation construction method and a pier construction method. The pile foundation construction method comprises the following steps that a steel beam is fixed to a soil body on the periphery of a preset pile hole; at least one part of a steel pipe column is placed in the preset pile hole, and the other part of the steel pipe column is exposed out of the soil body; the steel pipe column is fixed to the steel beam; and concrete is injected into the preset pile hole through the steel pipe column, so that the steel pipe column is connected with the stratum through the condensed concrete. According to the technical scheme of the pile foundation construction method, the technical problem that in the prior art, a pile foundation of a temporary support is prone to moving due to concrete buoyancy and disturbance is solved.

Owner:中铁二十局集团第三工程有限公司

Integrate the layout of subway stations and sections in a single section and mechanized rapid construction methods

ActiveCN113006813BReduce demolitionThe overall impact is smallUnderground chambersTunnel liningArchitectural engineeringSubway station

The invention discloses a layout and construction steps for integrating subway stations and sections in a single section, wherein the layout includes large-diameter single-hole tunnels that meet the requirements of double-layer subway tunnel boundaries and station platform hall building boundaries. The station hall section with functions such as access and buffering of passenger flow is tested; the underground shopping mall section is extended on both sides of the station hall floor; the construction method includes the following steps: using a large-diameter shield, and using a tunnel boring machine to construct several sections and stations at one time; Construction of the station platform plate and other structures in the station part of the diameter shield, and set up the wiring, and carry out the secondary construction of the station structure at the station; construct the urban pipe gallery, civil air defense, etc. in the spare space of the tunnel; construct the internal structure in the main line of the tunnel; Line track laying, electromechanical installation and decoration, joint debugging and joint testing, and trial operation; the construction method of the invention has the advantages of small comprehensive influence, fast construction speed, high safety factor, few abandoned projects, good quality assurance, and excellent comprehensive benefits.

Owner:SHANDONG TIEZHENG PROJECT EXPERIMENT & INSPECTION CENT

A display system for physics teaching experiments

ActiveCN111879660BEnables triple density measurementFunctional DiversificationTeaching apparatusSpecific gravity measurementLiquid densityEngineering

The invention relates to a physics teaching experiment display system, which includes a base and an experimental mechanism. The base is installed on the existing work table through sliding fit, and the upper end of the base is provided with an experimental mechanism. The invention adopts multiple density measurement The design concept of the structure is used to demonstrate the physics teaching experiment. The experimental mechanism set up as a whole has the function of realizing the triple density measurement of solid, liquid and gas with the cooperation of other density measurement structures, so as to make the overall function of the device more diversified and improve the overall practicality of the device. The sponge strip and the sponge block according to the present invention can use their own shape characteristics to absorb the liquid carried by the elastic dynamometer and the liquid remaining on the surface of the object, so as to minimize the impact of additional factors on the density measurement. The result will affect the probability of impact, thereby improving the accuracy of the density measurement of objects or liquids.

Owner:东台汇赢创融科技发展有限公司

Segment-assembled integrated bridge erecting machine and its construction method

ActiveCN112195798BAvoid frequent disassemblyAvoid replacementBridge erection/assemblyBridge materialsArchitectural engineeringPier

Owner:CCCC SECOND HARBOR ENG +1

Material stacking mechanism for automatic production line equipment for cap making

PendingCN112938602AIncrease the storage spaceExpand the stacking thicknessHatsPile receiversStructural engineeringAutonomation

The invention discloses a material stacking mechanism for automatic production line equipment for cap making. The material stacking mechanism comprises side baffles, trays and a telescopic table; guiders are arranged at the two ends of the telescopic table; outer guide rods are mounted at the bottoms of the guiders through bolts; the side baffles are welded to the bottoms of the outer guide rods; an inner guide rod is arranged between the outer guide rods; the top of the inner guide rod is located at the bottom end of the telescopic table; the trays are arranged between the outer guide rods and the inner guide rod; a supporting plate is mounted at the bottoms of the trays through bolts; and a lifter is mounted at one end of the bottom of the supporting plate through a fixing base. The material stacking mechanism can automatically stack shell fabric grabbed by a manipulator, the material stacking thickness can be adjusted, the automation degree is high, the stabilizing effect is good, and the material stacking mechanism is suitable for being widely used and popularized.

Owner:QINGDAO QIANFENG CAPART INTL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com