Device and method for constructing great depth rectangular or quasi-rectangular tunnel shield

A construction device, tunnel shield technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of increased construction costs and safety risks, increased construction difficulty, low space utilization, etc., and achieves reduction in construction organization and management. The effect of improving utilization rate and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

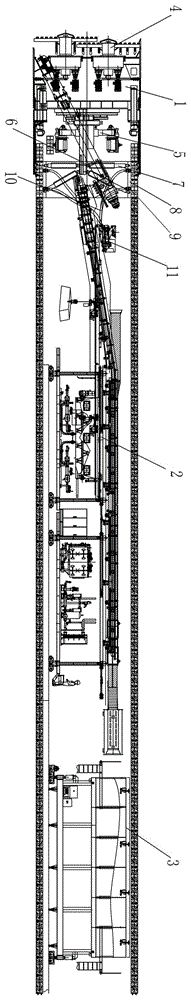

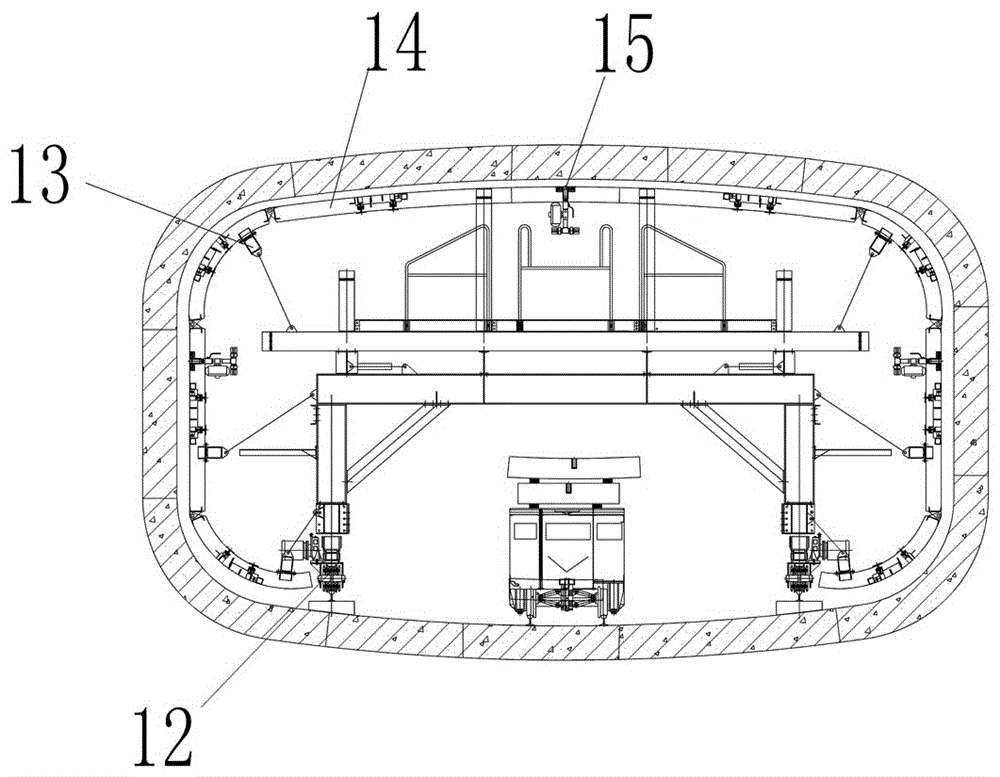

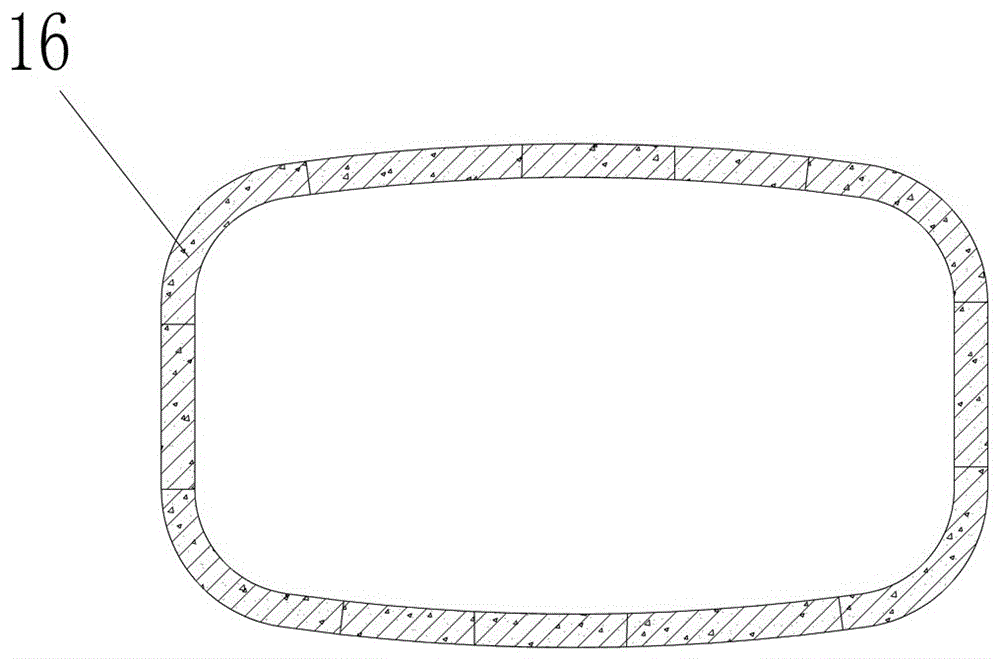

[0028] like Figure 1~3 As shown, there is provided a large buried depth rectangular or similar rectangular tunnel shield construction device, which is mainly composed of a shield main machine 1, a rear support 2, and a formwork trolley 3, and a combined rotating The cutter head 4 is provided with a rectangular segment assembly machine 5 at the rear end of the shield machine, and a template telescopic cylinder 7 is connected to the support cantilever beam 6 at the rear end of the rectangular segment assembly machine, and the other end of the template telescopic cylinder 7 A formwork 8 is connected and fixed, and a grouting port 9 is reserved on the formwork, and the grouting port is connected with a concrete grouting machine 11 through a pipeline 10, and the concrete grouting machine 11 is fixed on the front end of the rear matching 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com