Method for detecting deformation of metal bonding interface by second-order stress mutation angle

A technology of metal bonding and stress mutation, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of low detection frequency, low sensitivity, long wavelength, etc., and achieve the effect of sensitive micro deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific implementation cases and in conjunction with the accompanying drawings.

[0021] The invention determines the incident angle when the second-order stress changes abruptly by constantly changing the ultrasonic incident angle, and subtracts the incident angle of the actual stress sudden change from the critical angle of the theoretical stress sudden change to obtain the deformation angle between the metal bonding interface and the metal surface.

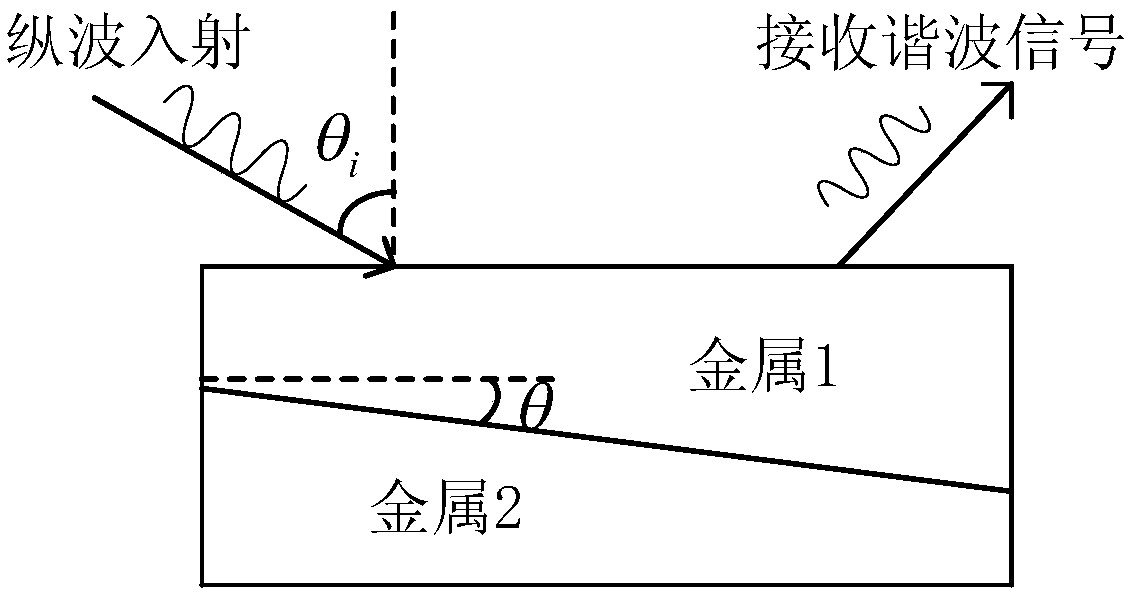

[0022] In this embodiment, aluminum alloy and steel bonding workpiece are selected, metal 1 is aluminum alloy, and metal 2 is steel, such as figure 1 shown.

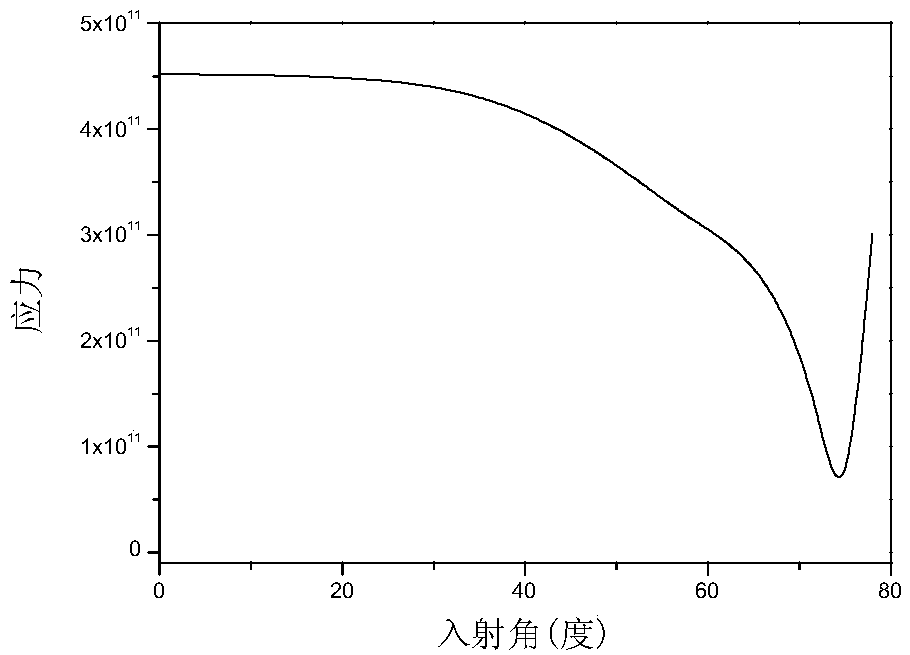

[0023] Determine the change curve of the metal bonding interface and the incident angle according to the relevant parameters of the metal, such as figure 2 shown.

[0024] (1) According to the relevant parameter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap