High-precision multi-range novel force sensor set of series structure

A technology of force sensor and series structure, applied in the field of new force sensor group of series structure, can solve the problems of low measurement accuracy and inability to measure large load, etc., and achieve the effect of good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

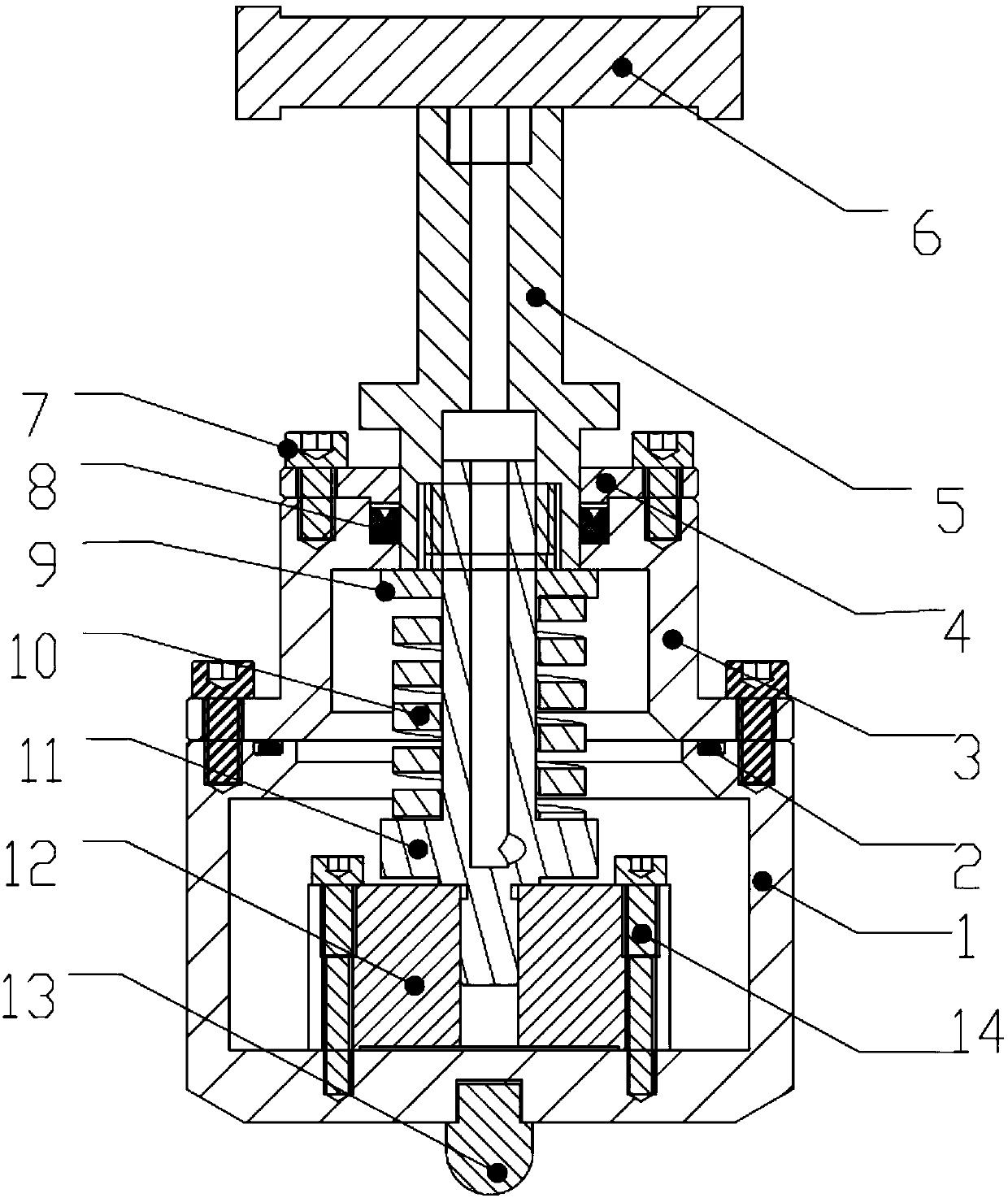

[0020] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0021] A new force sensor group with high-precision multi-range series structure is composed of small-range force sensors (such as range F1) and large-range force sensors (such as range F2, and F1,<F2) combined in series. When applied After the load, the spring is compressed, and the corresponding load value is detected by the small sensor. When the load does not exceed the small range F1, the small range force sensor and the large range force sensor work at the same time, and both can collect data. When the load reaches the small range F1 , the spring reaches the maximum compression, and the lower end of the loading rod is in contact with the sealing plate, which acts as a limiter, that is, there is no relative displacement between the loading rod and the sealing plate, the small-range force sensor is protected, and only the large-range force sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com