Pre-existing crack offset three-point bending test device for testing fracture toughness of II type crack

A technology of prefabricated cracks and fracture toughness, which is applied in the direction of measuring devices, testing material strength by using one-time impact force, and testing material strength by applying stable bending force, which can solve the problem of no standard research on the growth rate of type II cracks, and achieve The effect of easy test piece and simple test piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

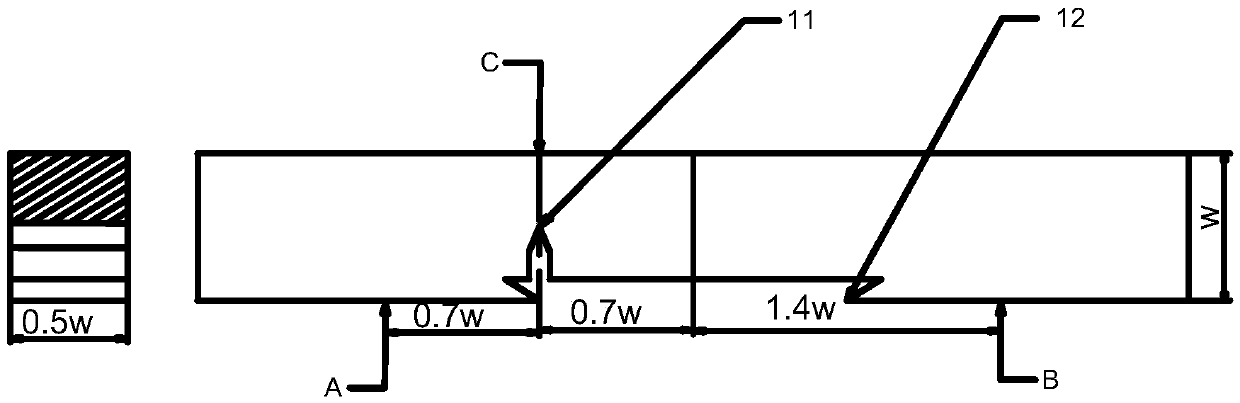

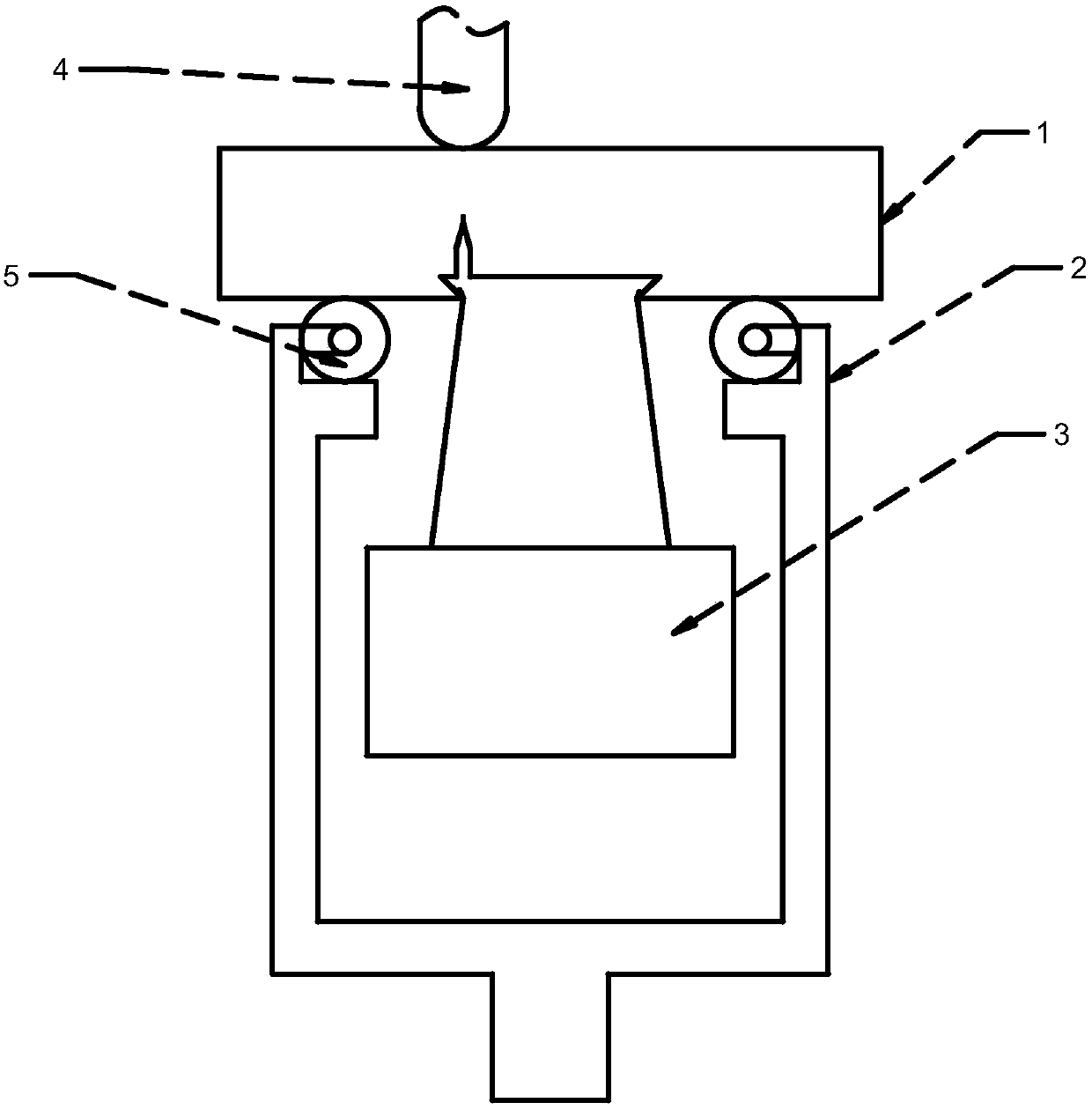

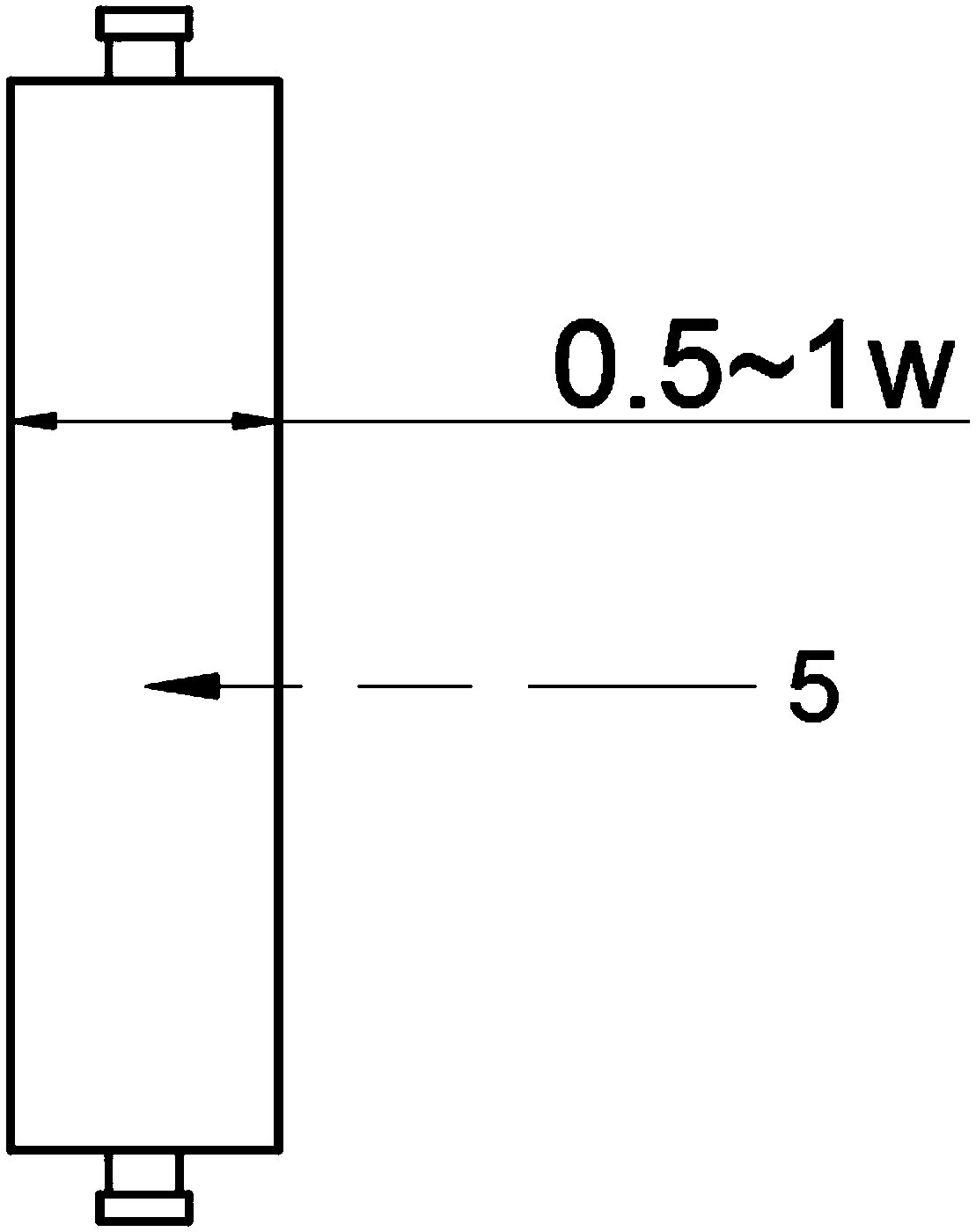

[0023] Such as figure 1 As shown, a schematic diagram of a prefabricated crack offset three-point bending specimen used to test the fracture toughness of a type II crack, in which A, B, and C are force application points, and the specimen 1 is a rectangular flat specimen with a length of ﹥width﹥thickness, assuming that the width of sample 1 is W, the length is greater than or equal to 4 times the width, and the thickness dimension is 1 / 2 of the width dimension; as shown in the figure, the V-shaped opening groove 11 at the tip is located On the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com