A method for screening process parameters of dredging yield or energy consumption based on a main base analysis method

A screening method and technology of process parameters, applied in data processing applications, instruments, complex mathematical operations, etc., can solve problems such as low output, high energy consumption in dredging operations, and difficulty in qualitative testing, and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

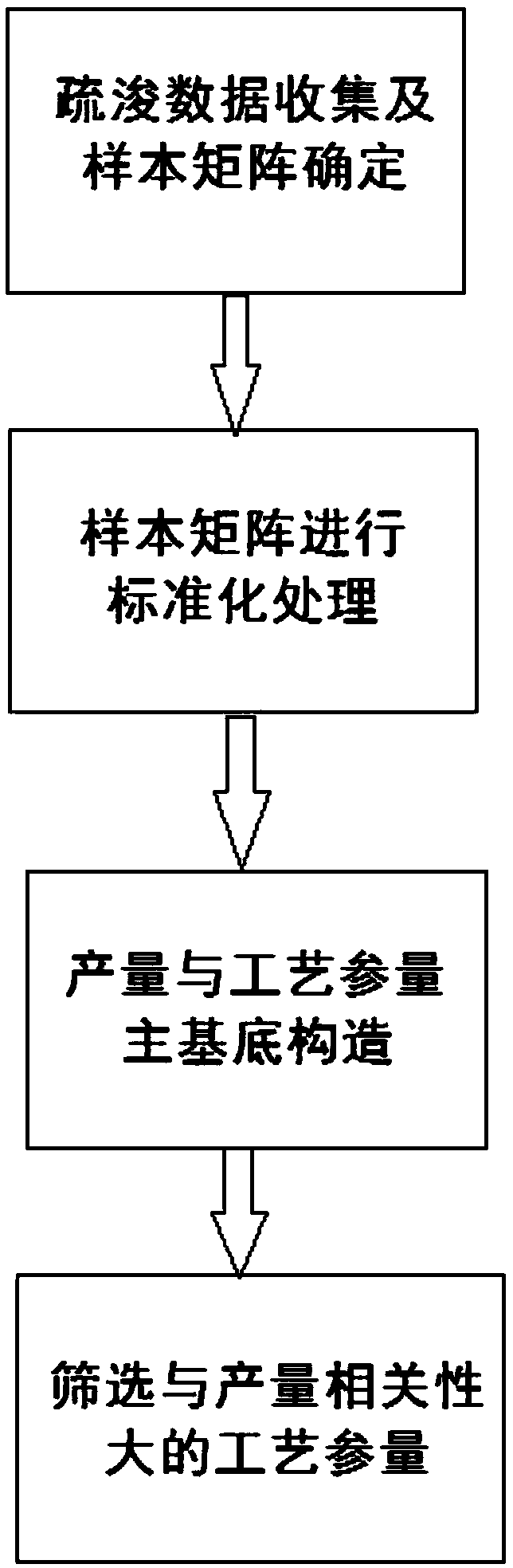

[0093] Embodiment 1 dredging production process parameter screening method

[0094]Step 1.1: Collect data on output and process parameters in dredging operations. In Example 1, the main process parameters of dredging include reamer rotating speed (Reamer rotating speed, RS), pump suction pressure (Pump suction pressure, PSP), pump discharge Pressure (Pump discharge pressure, PDP), suction vacuum (Suctionvacuum, SV), pump shaft speed (Pump shaft speed, PSS), submerged pump speed (Submerged pump speed, SPP), traverse speed (Transverse speed, TS), Pipeline average concentration (Pipeline average concentration, PAC), pipeline flow velocity (Line velocity, LV), outlet flow velocity (Export flow velocity, EFV), reamer cutting mud thickness (Reamer cutting mud thickness, RCMT), reamer advance distance ( Reamerforward distance (RFD) has a total of 12 parameters and a dependent variable, that is, Production per second (PPS).

[0095] The data in Example 1 are collected in real time fr...

Embodiment 2

[0133] Embodiment 2 Dredging Energy Consumption Process Parameter Screening Method

[0134] Step 2.1: Collect data on energy consumption and process parameters in dredging operations. In this example, the main dredging process parameters include reamer rotating speed (RS), pump suction pressure (PSP), pump discharge Pressure (Pump discharge pressure, PDP), suction vacuum (Suction vacuum, SV), pump shaft speed (Pump shaft speed, PSS), submerged pump speed (Submerged pump speed, SPP), traverse speed (Transverse speed, TS) , pipeline average concentration (Pipeline average concentration, PAC), pipeline flow velocity (Line velocity, LV), outlet flow velocity (Export flow velocity, EFV), reamer cutting mud thickness (Reamercutting mud thickness, RCMT), reamer advancing distance (Reamer forward distance, RFD) has a total of 12 parameters and a dependent variable, that is, energy consumption per second (ECPS).

[0135] The data in this example 2 comes from the real-time collection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com