Water cooling motor

A water-cooled motor and motor housing technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of limited and complex motor structure, and achieve the effects of reducing manufacturing and assembly costs, long service life, and stable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can imagine various implementations of the present invention without changing the essence and spirit of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

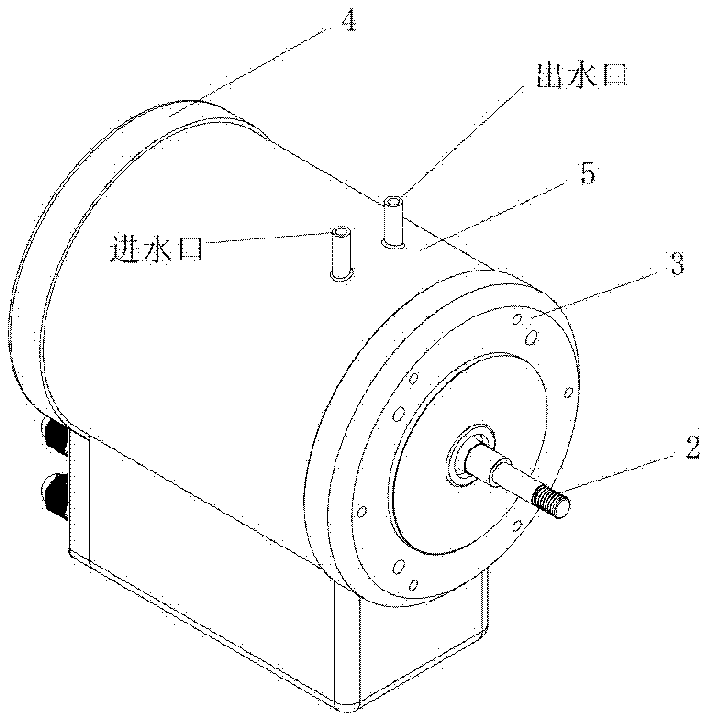

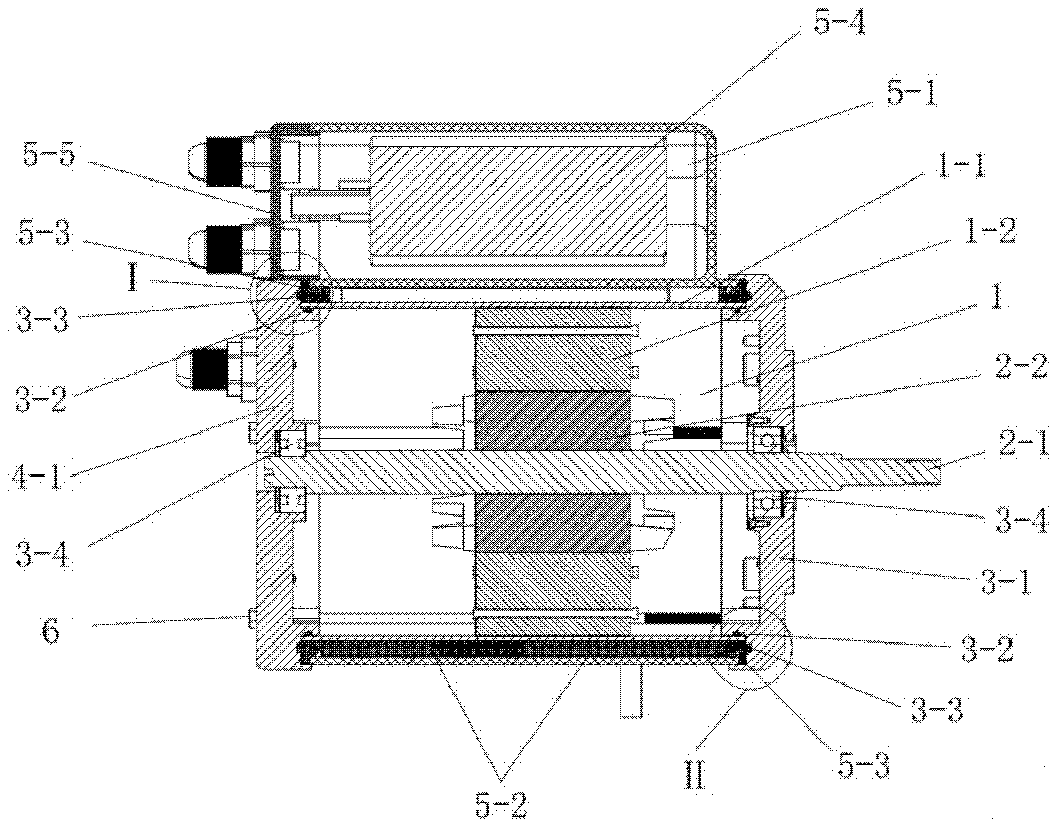

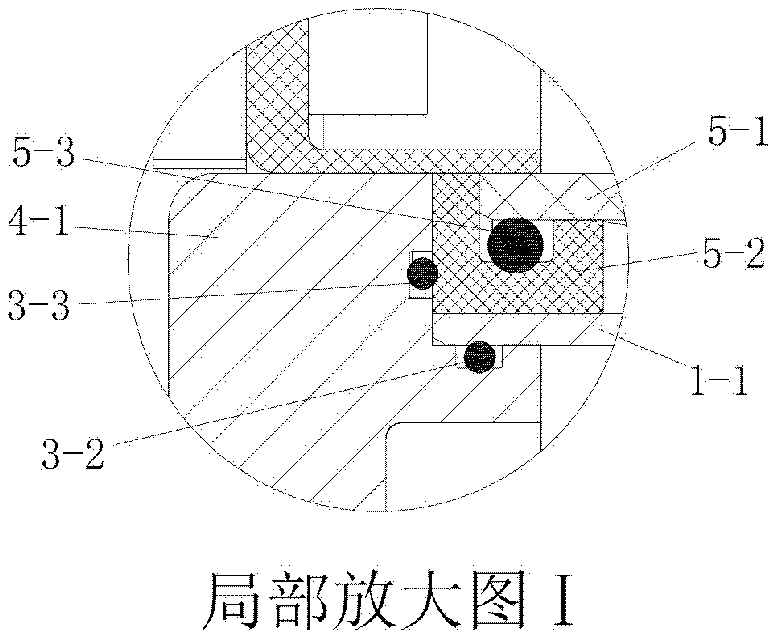

[0030] combine figure 1 , The water-cooled motor shown in this embodiment includes a stator assembly 1 , a rotor assembly 2 , a front end cover assembly 3 , a rear end cover assembly 4 , an outer cylinder assembly 5 , and bolts 6 .

[0031] The stator assembly 1 includes an inner cylinder 1-1 and a stator coil assembly 1-2 located inside the inner cylinder 1-1, both of which are fastened and fixed by tooling;

[0032] The rotor assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com