Low-pressure nozzle

A technology of low-pressure nozzles and nozzles, applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of large net pressure loss, uneven distribution of paint, large input pressure and pressure difference, etc., and achieve the service life of the equipment The effect of prolonging and improving the coating effect and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

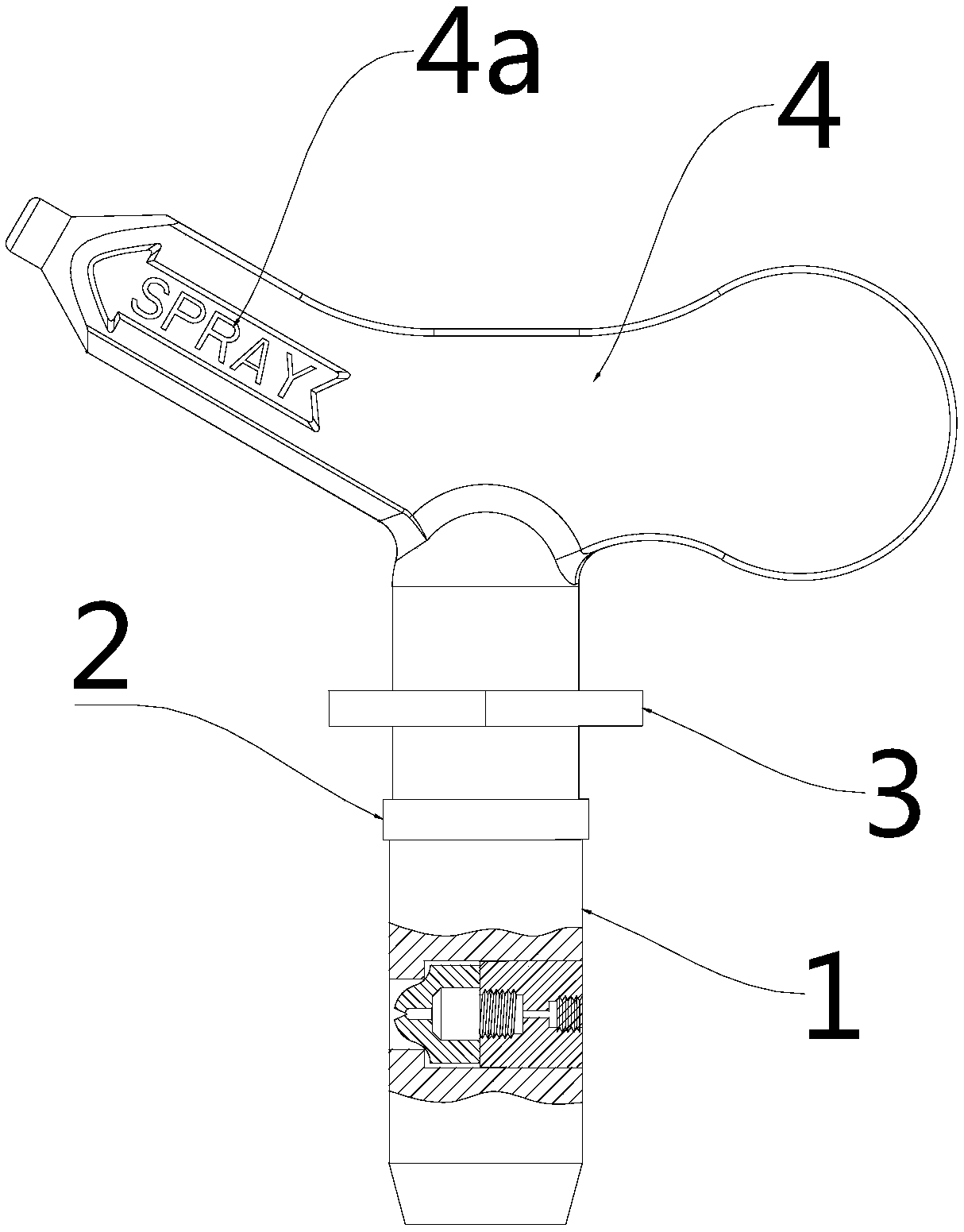

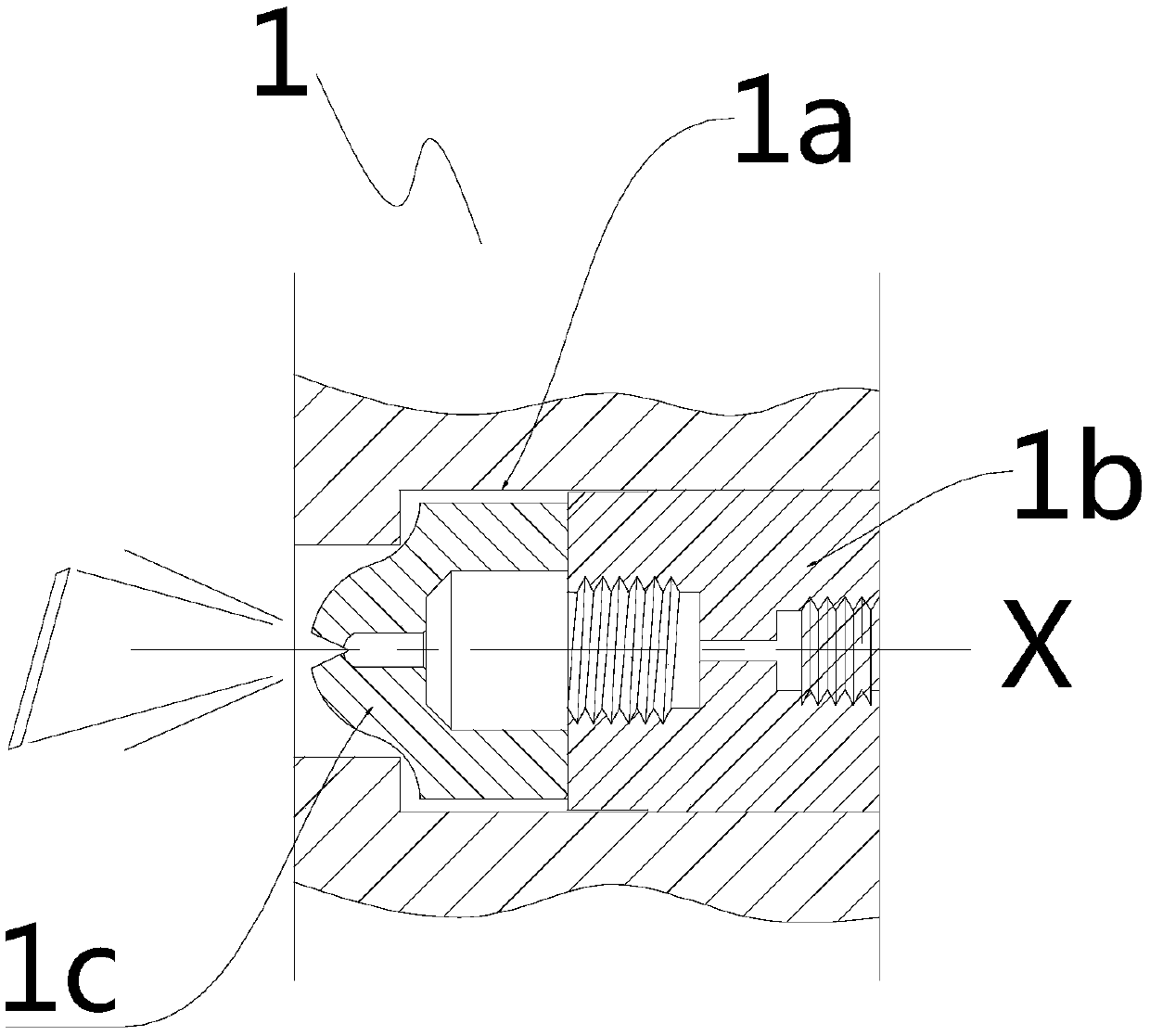

[0046] Such as Figure 2 to Figure 5 As shown, a low-pressure nozzle includes a nozzle body 1, which is made of stainless steel as a whole. There is an installation hole 1a in the middle of the nozzle body 1 along the X direction, and the installation holes 1a are installed sequentially along the X direction in the feeding direction. There are interconnected pre-atomization parts 1b and tip atomization parts 1c. The pre-atomization part 1b is opened along the X direction with a sequentially connected feed channel 1b1, pre-atomization channel 1b2 and pre-atomization pressure stabilization channel 1b3. , the feed channel 1b1, the pre-atomization channel 1b2 and the pre-atomization pressure stabilization channel 1b3 have a dumbbell-shaped structure as a whole, and the tip atomiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com