Magnetic sphere body milling and meridian and latitude carving processing method

A processing method and technology of warp and latitude lines, which are applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of inability to complete high-precision warp and weft line engraving processing, etc., and achieve low processing cost, consistent depth and beautiful appearance, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

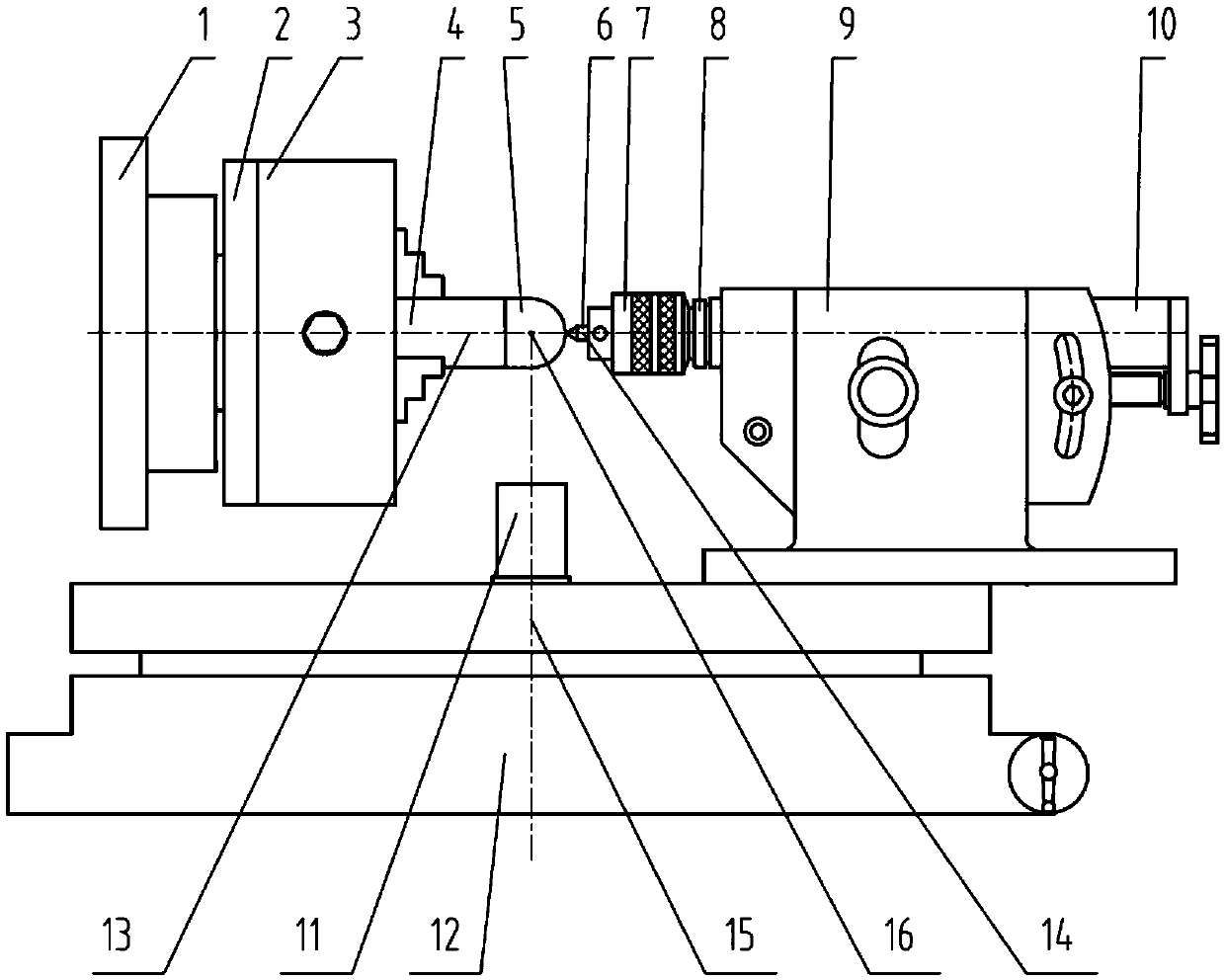

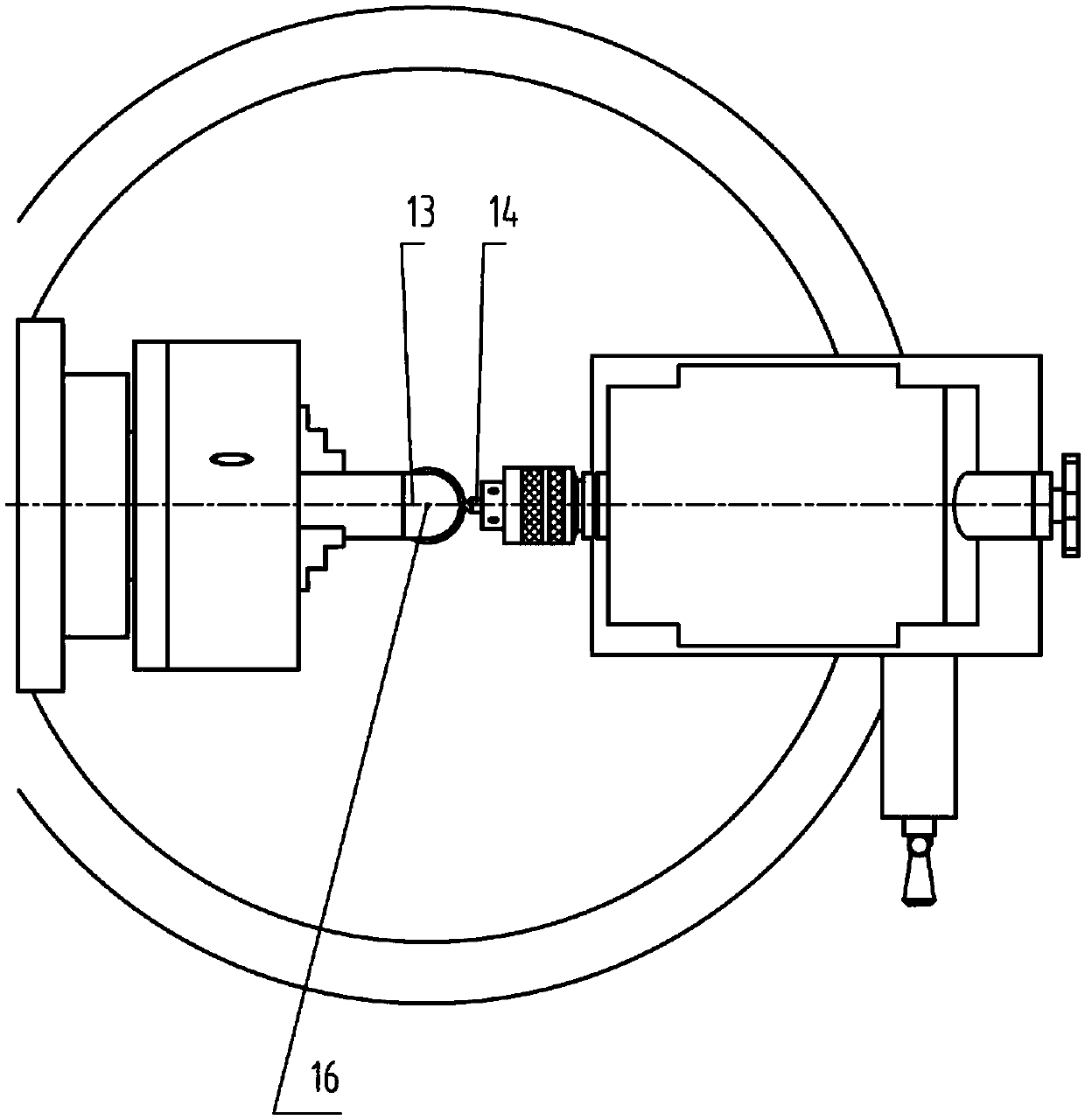

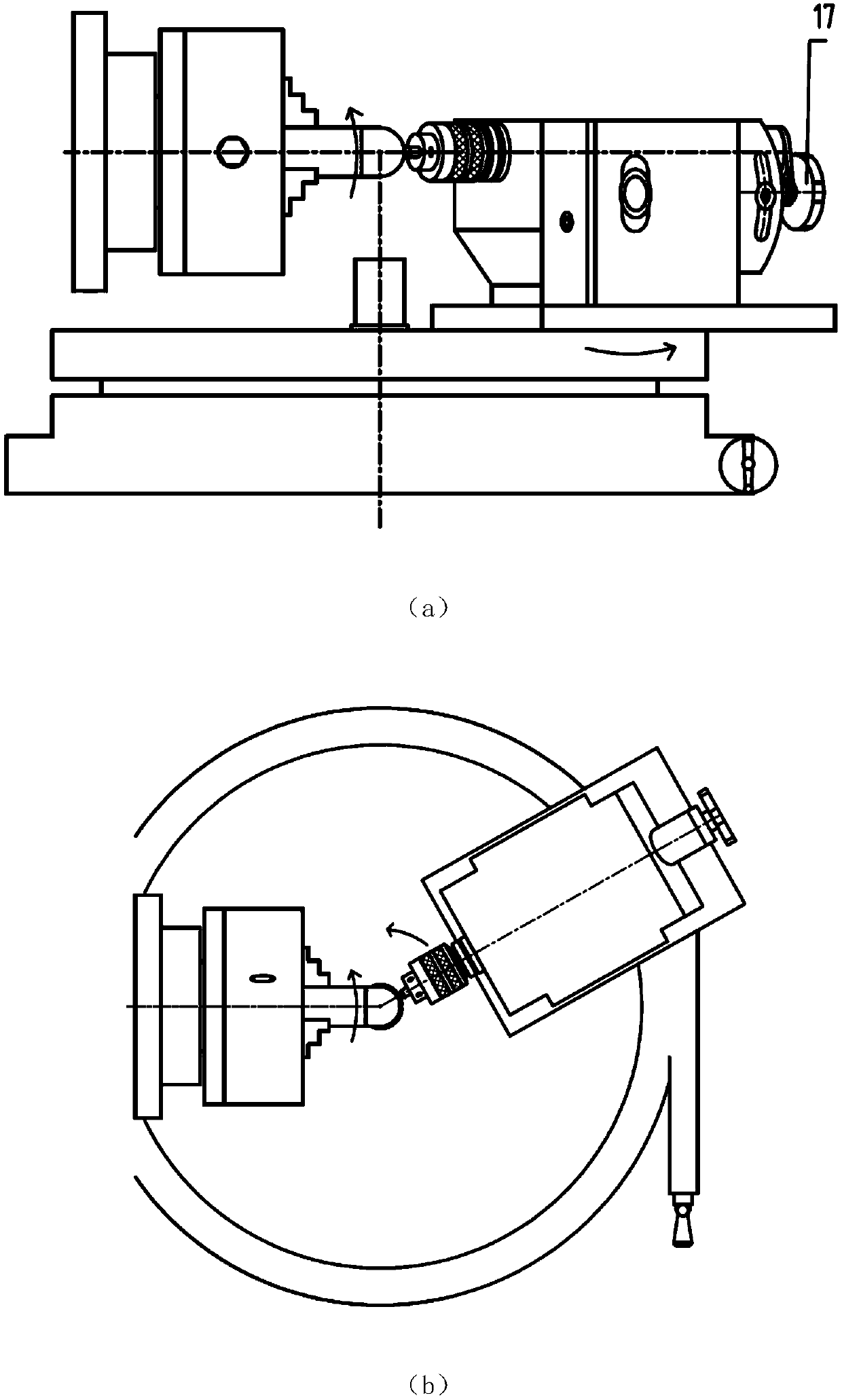

[0029] The processing equipment involved in the present invention: milling machine (universal milling machine X8130), intermediate sleeve 2 with angular index scale, three-jaw chuck 3, thread clamp 4, magnetic ball 5, cutter 6, drill chuck 7, intermediate sleeve 8, Tailstock 9, centering shaft 11, rotary table 12. The tailstock 9 is fixedly connected to the rotary table 12 on top, the intermediate sleeve 8 is installed on the tailstock 9, the drill chuck 7 is installed on the intermediate sleeve 8, the drill chuck 7 clamps the tool 6, and the intermediate sleeve with angular graduation scale 2 is installed on the spindle 1 of the milling machine, the three-jaw chuck 3 is fixedly connected with the middle sleeve 2 with an angular index scale, the three-jaw chuck 3 clamps the threaded fixture 4, and the magnetic ball 5 is screwed on the threaded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com