Stacked oil-cooler vacuum brazing clamp

An oil cooler, stacked technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of welding seam gap, no limit function, ultra-low product height and dimension, so as to prevent deformation and distortion, The effect of improving the qualified rate of brazing and avoiding the over-tolerance in the height direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

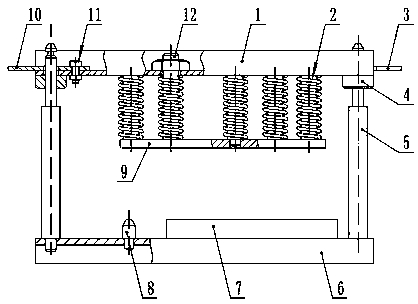

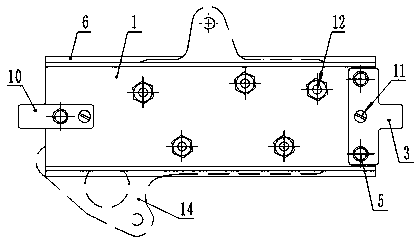

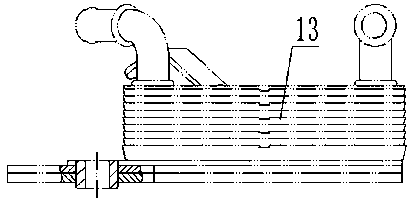

[0013] Such as Figure 1~4 As shown, the present invention includes a positioning assembly and a pressing assembly.

[0014] The positioning assembly is composed of a support block 7 and a positioning pin 8 fixed on the surface of the lower channel steel 6, and three support shafts 5 with a stepped structure fixed on the surface of the lower channel steel 6, and the three support shafts 5 are triangularly distributed.

[0015] The pressing assembly is fixed on the lower end of each stud 12 by the upper channel steel 1 supported on the three support rods 5, the studs 12 which pass upward through the upper channel steel and respectively connected with the nuts (not shown in the figure). The pressing plate 9, the spring 2 that is positioned between the pressing plate and the upper channel steel 1 and is installed on each stud 12 respectively constitute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com