Adjustable eccentric wheel clamp

An adjustable wheel clamping technology, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of easy damage to the surface of the workpiece, low efficiency, poor universality of the clamping, etc., to save materials, improve versatility, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

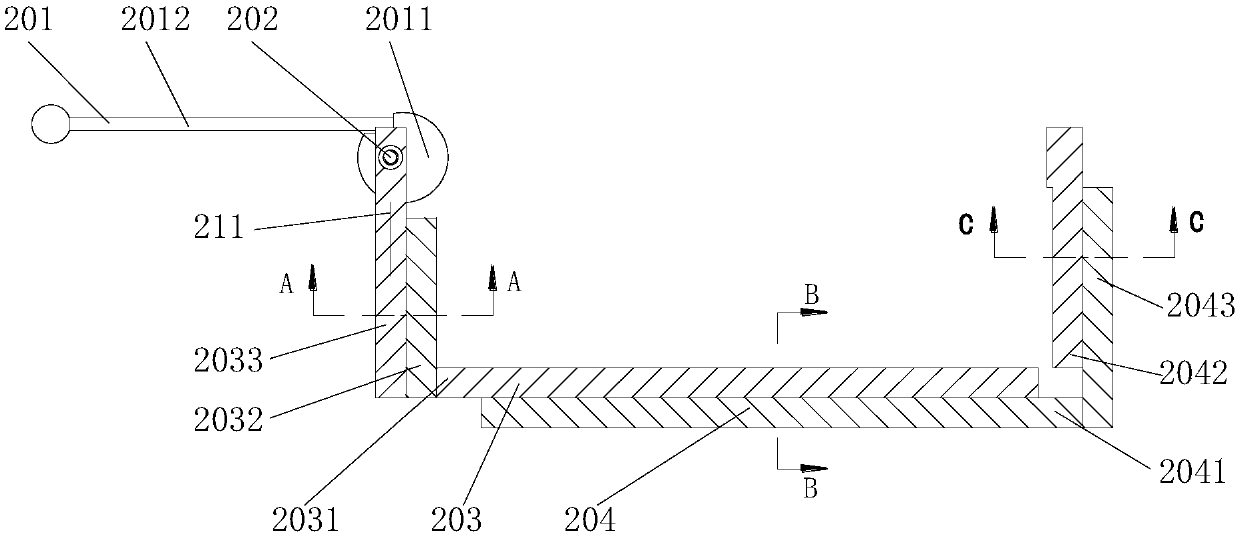

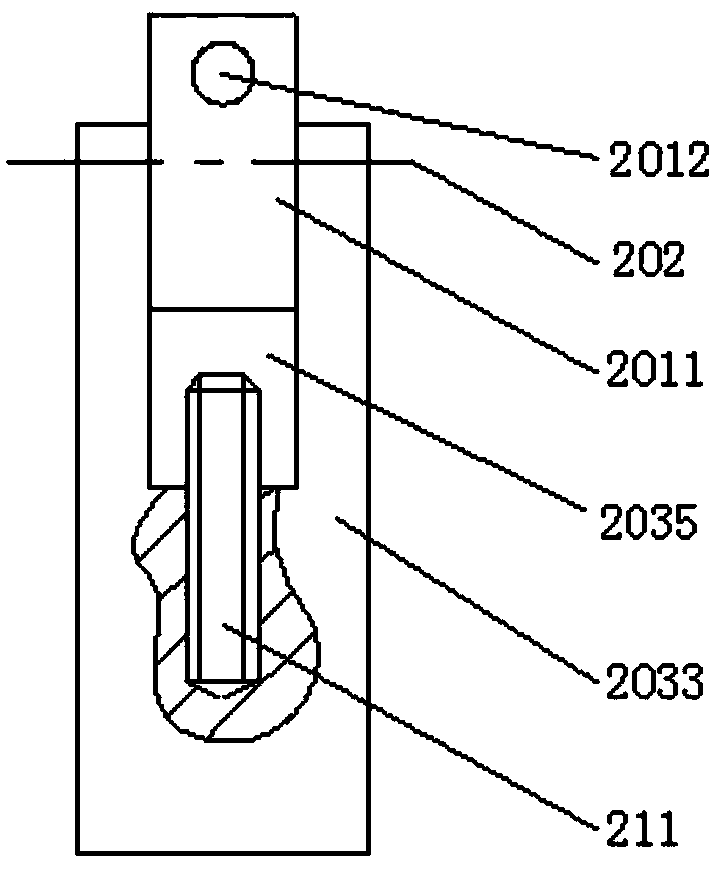

[0035] refer to figure 2 and image 3 , the cardan includes a cam mechanism 201, a first bracket 203, a second bracket 204 and a cam adjustment mechanism. Both the first bracket 203 and the second bracket 204 are "L" shaped, and the first bracket 203 is inserted into the second bracket 204 horizontally. The cam mechanism 201 is installed in the groove 2035 on the upper part of the first bracket 203 through the connecting bolt 202 . The cam mechanism 201 includes a cam 2011 and a handle 2012 . A cam adjustment mechanism is arranged in the groove 2035 to adjust the opening of the cam. The cam adjustment mechanism in this embodiment adopts an adjustment screw 211, and the adjustment screw 211 is installed at the bottom of the groove 2035. When the opening of the cam needs to be adjusted , just adjust the screw-in depth of the screw 211.

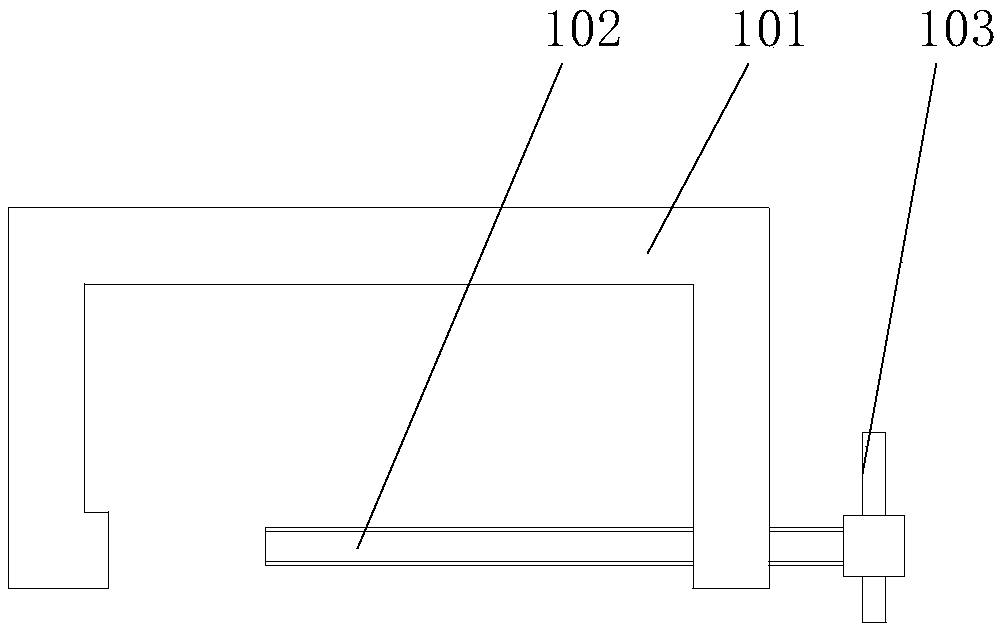

[0036] refer to figure 1 , the first bracket 203 includes a first bracket body and a cam mounting plate 2033 . The first bracket main bo...

Embodiment 2

[0042] refer to Figure 7 and Figure 8, Embodiment 2 is similar in structure to Embodiment 1, the only difference is that the cam adjustment mechanism in Embodiment 2 uses an adjustment block 212, and the adjustment block 212 is fixed on the inner wall of the groove 2035 by screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com