Intermittent granulation material automatic weighing device

An automatic weighing, intermittent technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problems of slow weighing speed, low weighing efficiency, multi-manpower, etc., and achieve accurate weighing and feeding and placing. The effect of reducing the input of labor and saving the input of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides an intermittent automatic weighing and counting device.

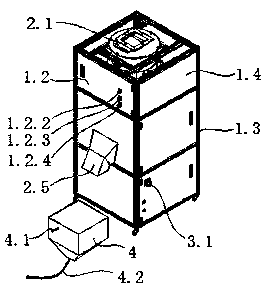

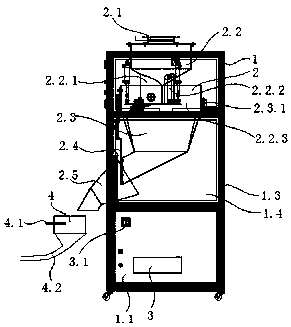

[0030] The equipment includes: a box 1, a weighing system 2, and an electrical control system 3; the weighing system 2 is installed in the box, and the electrical control system 2 controls the weighing, feeding and discharging of the weighing system 2.

[0031] The weighing system 2 includes: a gate valve 2.1, a storage hopper 2.2, a weighing hopper 2.3, a total discharge valve 2.4, and a discharge port 2.5.

[0032] The flapper valve 2.1 is provided with a flange 2.1.1, and the flange 2.1.1 is used to connect with the funnel of the granulator, and the feeding and stopping of feeding are realized by controlling the opening and closing of the flange 2.1.1.

[0033] A storage hopper 2.2 is provided below the gate valve 2.1, a large discharge valve 2.2.1 and a small discharge valve 2.2.2 are installed below the storage hopper 2.2, and a large discharge valve 2.2.1 and a small discharge valve...

Embodiment 2

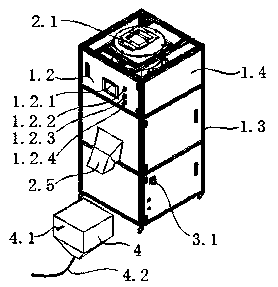

[0045] This embodiment provides an intermittent automatic weighing and counting device.

[0046] The equipment includes: a box 1, a weighing system 2, and an electrical control system 3; the weighing system 2 is installed in the box, and the electrical control system 2 controls the weighing, feeding and discharging of the weighing system 2.

[0047] The weighing system 2 includes: a gate valve 2.1, a storage hopper 2.2, a weighing hopper 2.3, a total discharge valve 2.4, and a discharge port 2.5.

[0048] The flapper valve 2.1 is provided with a flange 2.1.1, and the flange 2.1.1 is used to connect with the funnel of the granulator, and the feeding and stopping of feeding are realized by controlling the opening and closing of the flange.

[0049] A storage hopper 2.2 is provided below the gate valve 2.1, a large discharge valve 2.2.1 and a small discharge valve 2.2.2 are installed below the storage hopper 2.2, and a large discharge valve 2.2.1 and a small discharge valve 2.2.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com