A damping half-bridge pilot control on-off valve

A pilot control, half-bridge technology, applied in the direction of servo motor components, mechanical equipment, fluid pressure actuators, etc., can solve the problems that cannot overcome the hydraulic force to push the spool, increase the volume of the switch valve, and increase the complexity. Achieve the effects of improving the ability to resist external disturbances, reducing the size of the specifications, and reducing the control power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

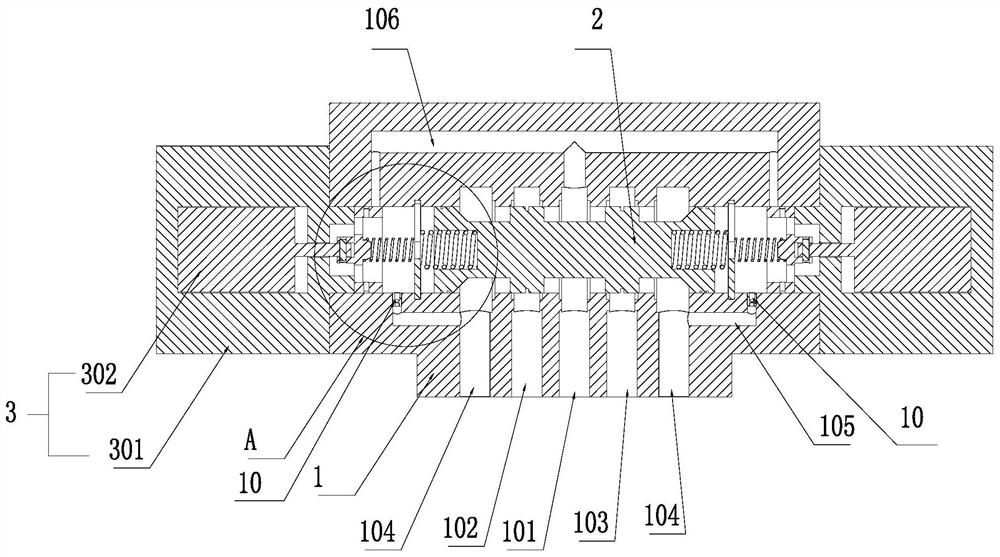

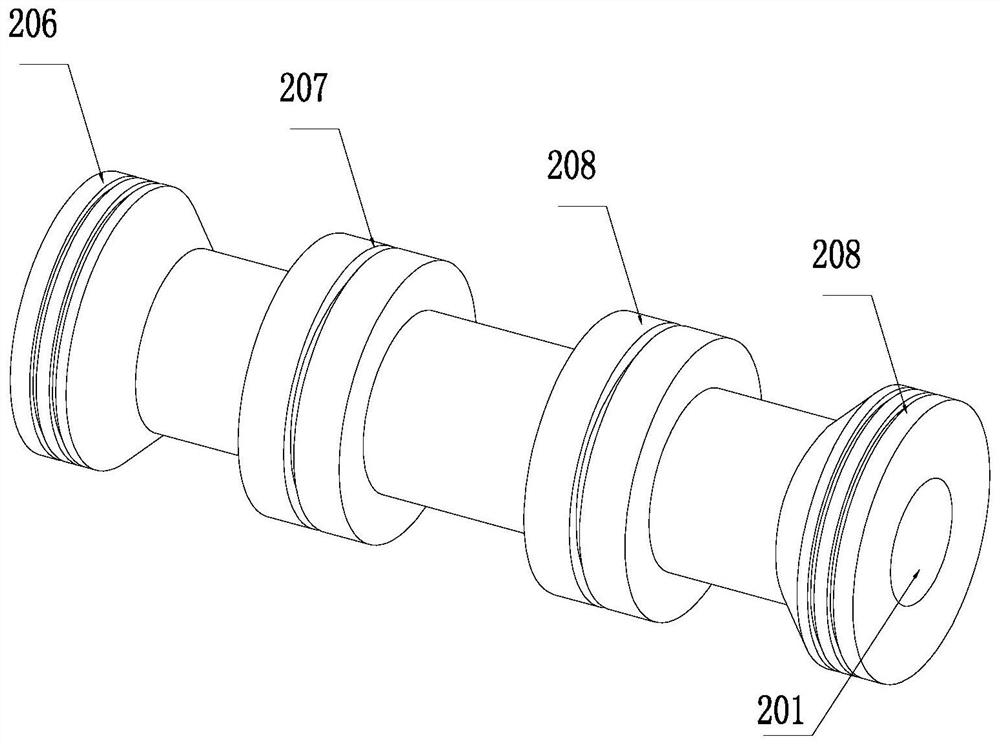

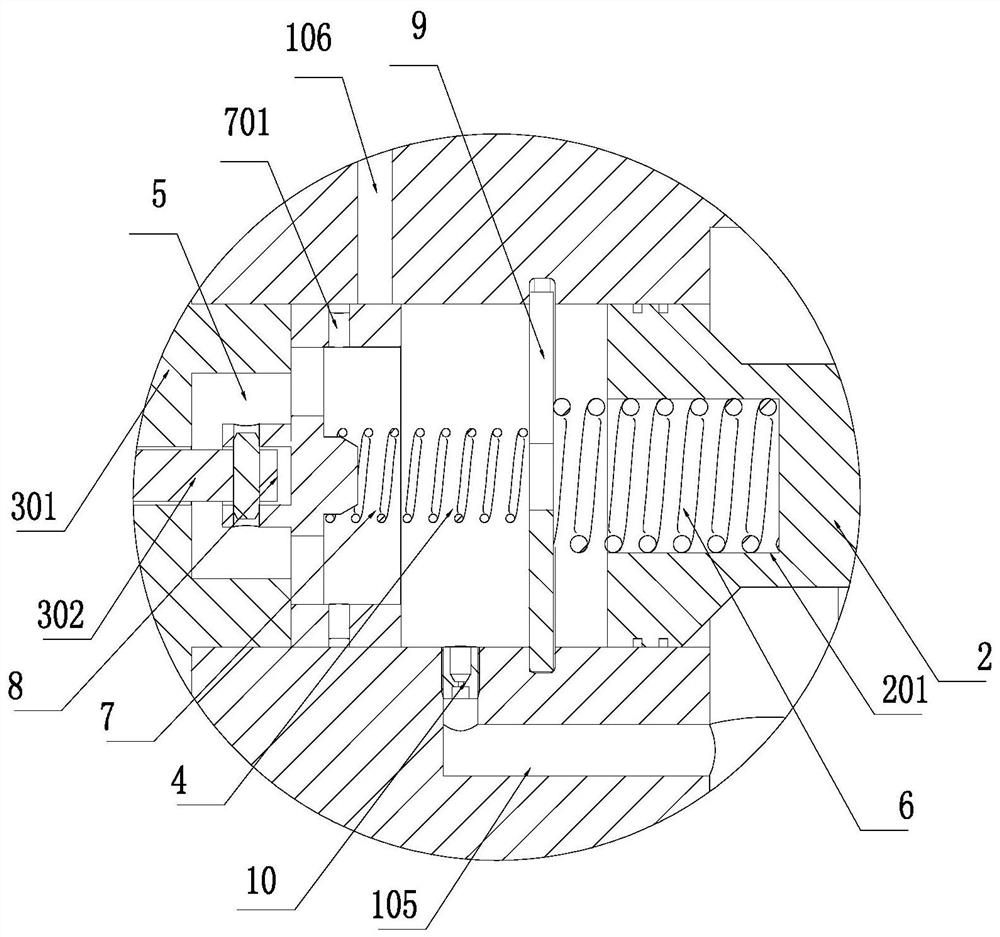

[0036] Such as figure 1As shown, a damping half-bridge pilot control switching valve includes a valve body 1 and a main valve core 2. The valve body 1 is provided with a high-pressure oil inlet 101, a first control oil port 102, and a second control oil port. 103. Two low-pressure oil outlets 104 (can be 0 pressure), two low-pressure oil outlets 104 are set on both sides, high-pressure oil inlet 101 is set in the middle, the first control oil port 102, the second control oil port 103 respectively arranged between the two low-pressure oil outlets 104 and the high-pressure oil inlet 101, such as figure 2 As shown, the main valve core 2 is provided with a first protruding ring 206, a second protruding ring 207, a third protruding ring 208, and a fourth protruding ring 209 in the circumferential direction, and the first protruding ring 206 and the fourth protruding ring 209 are respectively located at The two ends of the main spool 2 are in dynamic sealing cooperation with the v...

Embodiment 2

[0049] Such as Figure 5 As shown, a damping half-bridge pilot control switching valve includes a valve body 1 and a main valve core 2. The valve body 1 is provided with a high-pressure oil inlet 101, a first control oil port 102, and a second control oil port. 103. Two low-pressure oil outlets 104 (can be 0 pressure), two low-pressure oil outlets 104 are set on both sides, high-pressure oil inlet 101 is set in the middle, the first control oil port 102, the second control oil port 103 They are respectively arranged between the two low-pressure oil outlets 104 and the high-pressure oil inlet 101. The main valve core 2 is provided with a first protruding ring 206, a second protruding ring 207, a third protruding ring 208, and a fourth protruding ring 209 in the circumferential direction. , the first protruding ring 206 and the fourth protruding ring 209 are respectively located at both ends of the main valve core 2 and are in dynamic sealing cooperation with the valve body 1 (t...

Embodiment 3

[0058] Such as Figure 8 As shown, an inflow damping half-bridge pilot control switching valve includes a valve body 1 and a main valve core 2. The valve body 1 is provided with a high-pressure oil inlet 101, a first control oil port 102, and a second control oil port. Port 103, two low-pressure oil outlets 104 (can be 0 pressure), two low-pressure oil outlets 104 are arranged on both sides, high-pressure oil inlet 101 is arranged in the middle, the first control oil port 102, the second control oil port 103 are respectively arranged between the two low-pressure oil outlets 104 and the high-pressure oil inlet 101, such as figure 2 As shown, the main valve core 2 is provided with a first protruding ring 206, a second protruding ring 207, a third protruding ring 208, and a fourth protruding ring 209 in the circumferential direction, and the first protruding ring 206 and the fourth protruding ring 209 are respectively located at The two ends of the main spool 2 are in dynamic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com