Apparatus for removing pin bones from fish fillets

A technology for fish steaks and equipment, applied in the application, processing, and slicing of fish, etc., can solve the problems of electric motor hindering heat dissipation, shortened service life, high operating temperature, etc., to avoid premature wear, compact design, easy to use. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

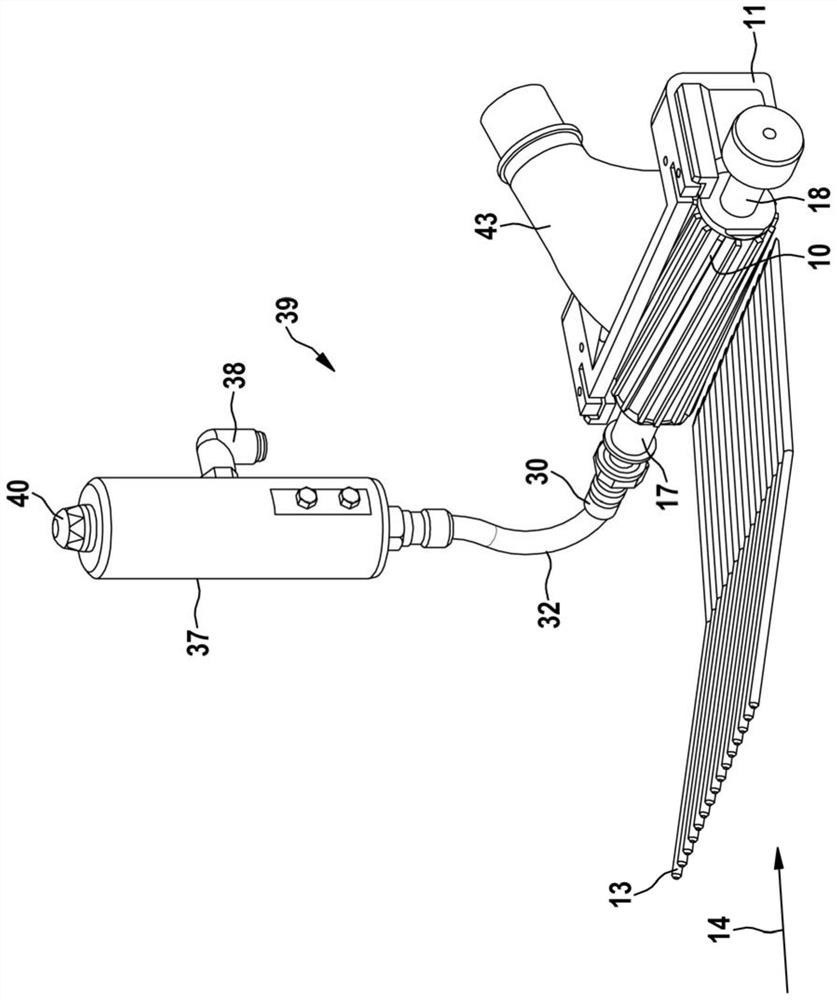

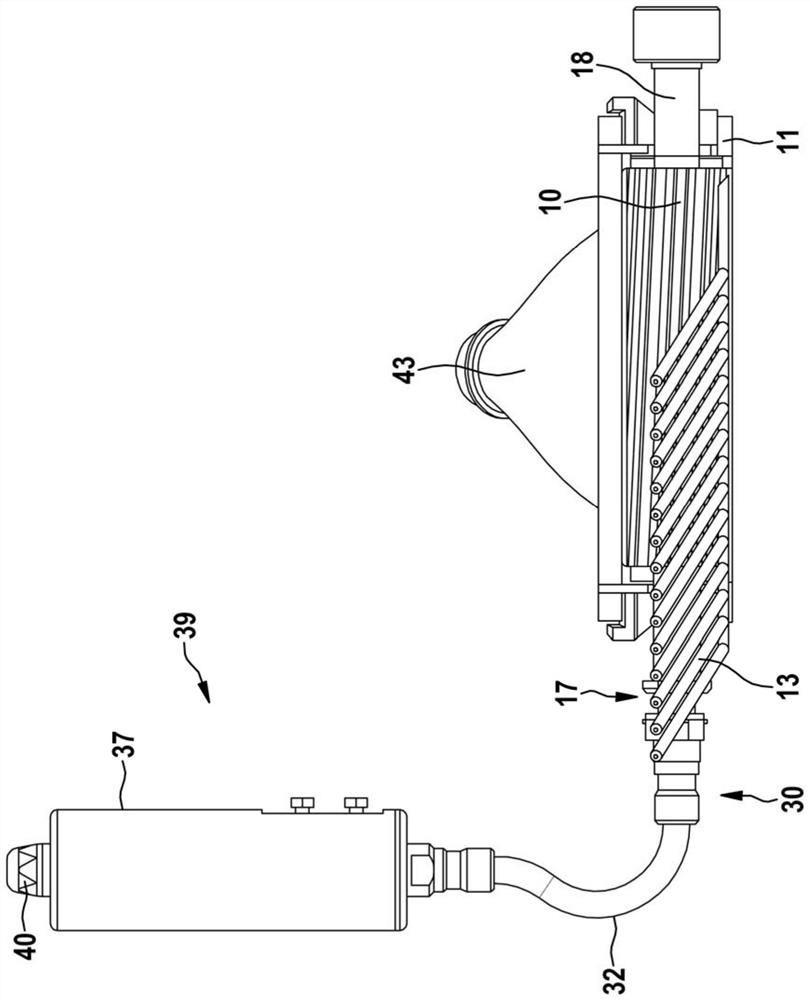

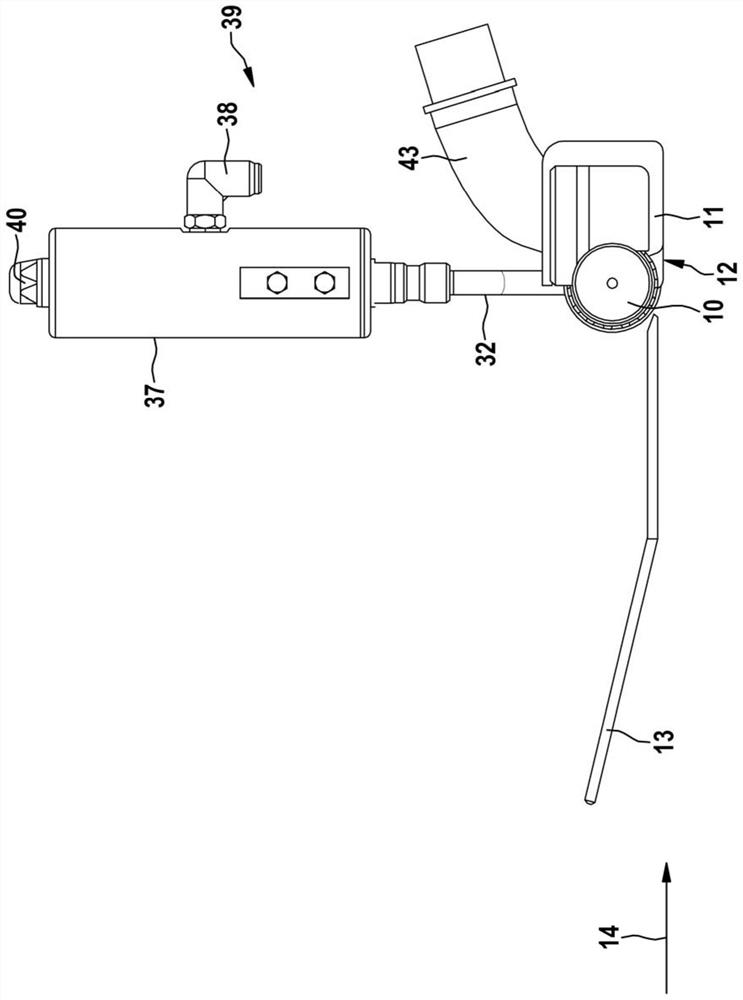

[0022] figure 1 The apparatus according to the invention is shown in a stereo manner. The device according to the invention is designed to fully automatically remove the needle bone from the fish. For this purpose, the fishing ruts not shown in the figure are continuously advanced by a suitable transport device according to the invention. For simplicity, such a transfer device is not shown in the figure.

[0023] The apparatus according to the invention comprises at least one shaped roller unit 10 that is rotatably supported. The roller unit 10 having the pressure receiving element 11 forms a clamping gap 12. The roller unit 10 and the pressure unit 11 are configured to grasp the needle bone in the clamping gap 12 and remove the needle in the fish rope by applying a pull force. Preferably, the apparatus according to the present invention includes a lower pressure clamping member 13, which is transmitted to the fisherna in which the equipment according to the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com