power conversion device

A power conversion device and DC voltage conversion technology, which is applied in electronic commutation motor control, electrical components, motor control, etc., can solve the problems of unrealistic driving characteristics and difficulty in calculating the magnetic pole position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

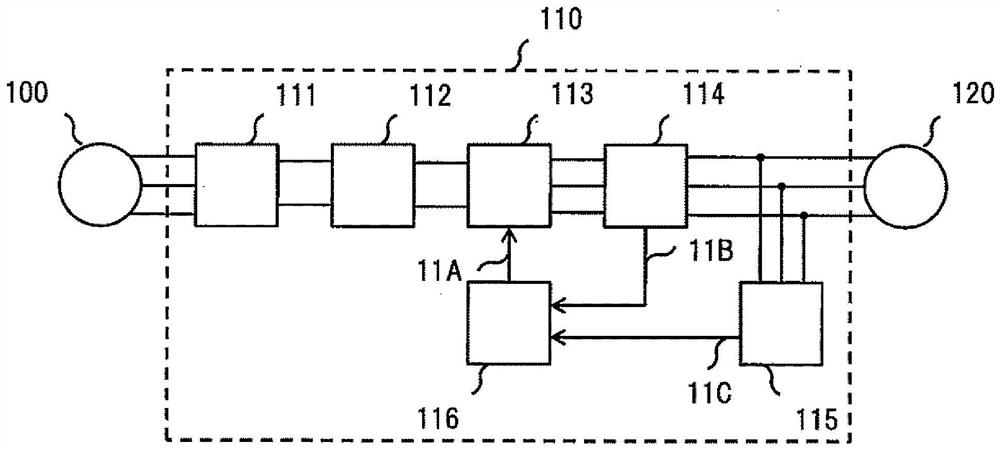

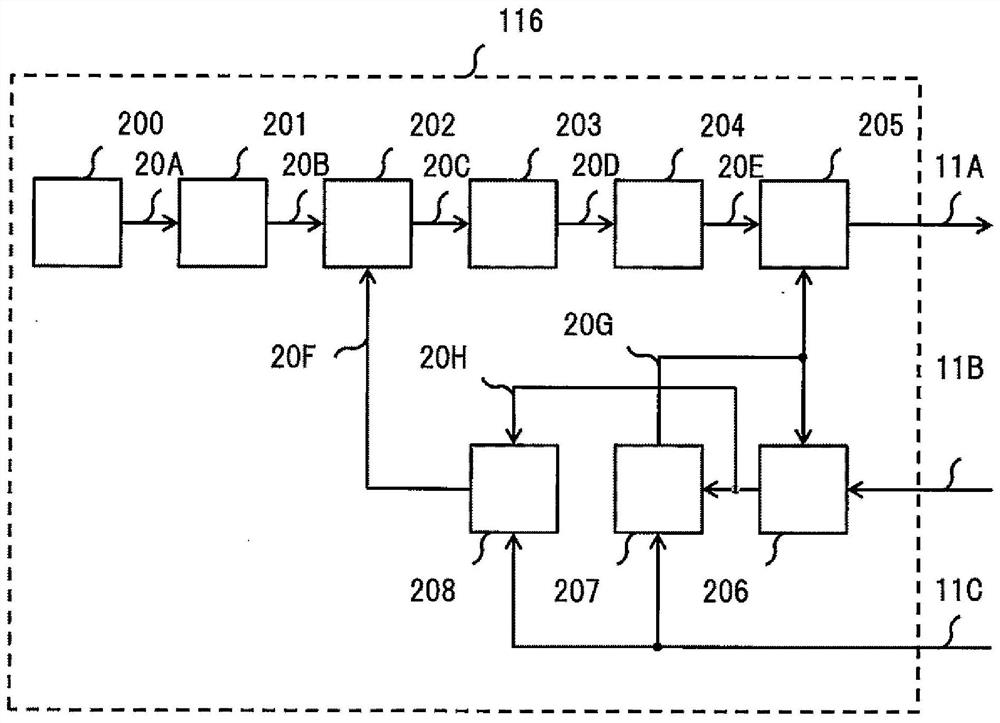

[0037] use figure 1 The control system for driving a synchronous motor according to the present embodiment and the overall configuration of a power conversion device equipped with the control system will be described.

[0038] A power conversion device 110 for driving a three-phase AC synchronous motor 120 includes a rectification circuit 111 , a smoothing circuit 112 , a switch circuit 113 , a current detection circuit 114 , a voltage detection circuit 115 , and a motor control unit 116 .

[0039] The three-phase AC voltage output from the three-phase AC power supply 100 is rectified by the rectification circuit 111 and smoothed by the smoothing circuit 112 to generate a DC voltage. A single-phase AC power supply may be used instead of the three-phase AC power supply 100 to rectify and smooth the single-phase AC voltage to generate a DC voltage. The rectification circuit 111 and the smoothing circuit 112 can also be removed, and the DC voltage can be obtained directly from t...

Embodiment 2

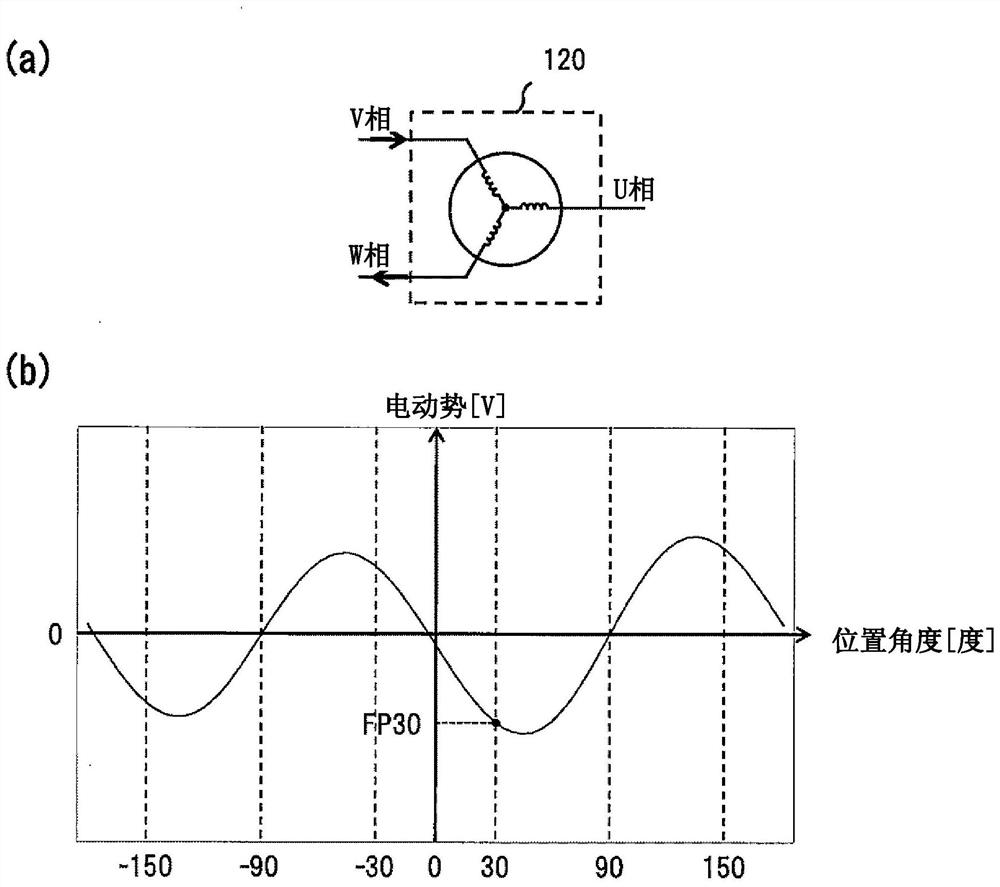

[0097] Embodiment 1 describes a driving method when the torque required for the rotor of the synchronous motor increases and the current also increases due to load generation. However, depending on the characteristics of the synchronous motor, the magnetic saturation electromotive force is sometimes affected not only by the magnitude of the current but also by the direction of the current. In such a synchronous motor, when the load fluctuates and the direction of the current flowing in the energized phase is reversed, for example, when the power running state is changed to the regenerative state, if only the magnitude of the current is considered as in the first embodiment If the magnetic pole position is detected, the magnetic pole position may not be detected accurately. Therefore, this embodiment is characterized in that the magnetic pole position is detected in consideration of the current direction as well as the magnitude of the current, and the three-phase AC synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com