Heat-not-burn cigarette cut tobacco module and preparation method thereof

A heat-not-burn and shredded tobacco technology, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve the problems of raw smoke and difficult to swallow, and achieve the effect of increasing the concentration of aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

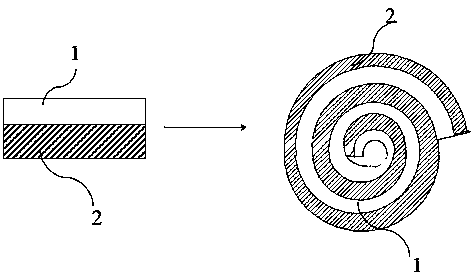

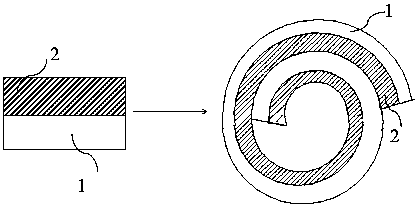

[0049] According to the formula and process in Table 1, mix guar gum, plant fiber, and metal powder, and then carry out wet copying molding to obtain a heat-conducting sheet base. In embodiment 1~5, the metal powder that selects is copper powder, and density ρ is 8.9g / m 3 , with a particle size of 8 μm.

[0050] Table 1

[0051]

[0052]

[0053] At the same time, the electron microscope scanning is carried out on the thermal conductive sheet, and it can be seen from the electron microscope lens that the copper powder particles in the thermal conductive sheet base are closely combined with the fibers through the bonding of the adhesive; the copper powder particles are in contact with each other, which can form a local The heat conduction chains, the heat conduction chains are connected and penetrate each other to form a heat conduction network that runs through the entire heat conduction sheet, so that the heat conduction performance of the heat conduction sheet is signif...

Embodiment 6~9

[0054] The preparation of embodiment 6~9 heat-conducting material

[0055] According to the formula and process in Table 2, 10 grams of binder, 100 grams of plant fiber, ρ×A×10 -6 Gram of metal powder (where ρ is the density of metal powder, the unit is g / m 3 , A is the conversion factor, and the value of A is 1.5) Carry out wet copying molding to obtain a heat-conducting sheet base.

[0056] Table 2

[0057]

Embodiment 10

[0060] The mensuration of embodiment 10 thermal conductivity

[0061] The thermal conductivity of the heat-conducting sheet bases of Examples 1-9, Comparative Examples 1, 2 and 3, the paper base of Comparative Example 4, and several commercially available cigarette sheets for non-burning cigarettes were measured.

[0062] The thermal conductivity is calculated according to the following formula:

[0063] TC=α×ρ×C

[0064] In the formula, TC is the thermal conductivity (w m-1 K-1), α is the thermal diffusivity (m2 s-1), and ρ is the density (kg m -3 ), C is the specific heat capacity (J·kg-1·K-1).

[0065] Measurement of thermal diffusivity α: measured with LFA457 analyzer at 30°C;

[0066] Density ρ: determined by the weight and size of the sample;

[0067] Specific heat capacity C: Measured with DSC 200F3 at 30°C.

[0068] table 3

[0069]

[0070] As can be seen from Table 3, the thermal conductivity of the thermally conductive sheet base prepared by the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density ρ | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com