Double-side efficient paint spraying equipment and paint spraying method

A paint spraying equipment and high-efficiency technology, applied in the field of painting, can solve the problems of paint film damage, paint waste, affecting the efficiency of painting, and achieve the effects of reducing paint waste, improving the scope of application, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

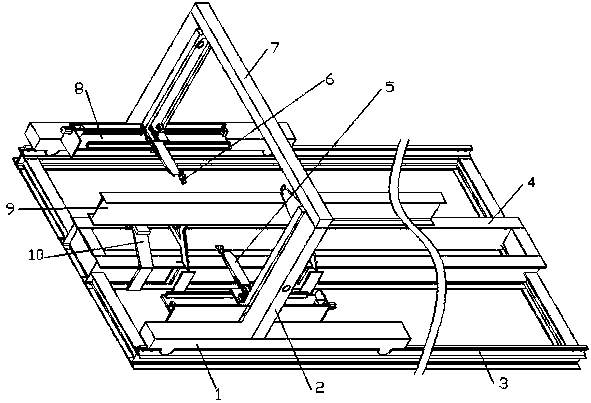

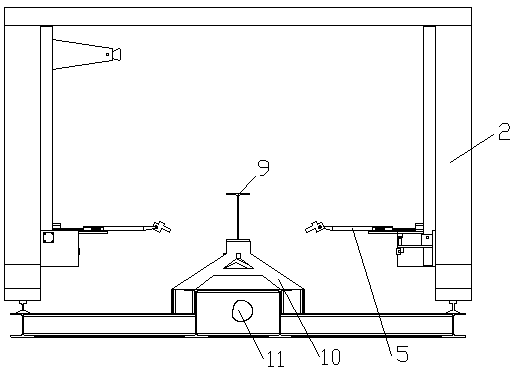

[0033] Such as figure 1 The double-sided high-efficiency painting equipment shown includes a workbench 4 extending longitudinally and main rails 3 located on both sides of the workbench 4 and extending longitudinally. The main rails 3 on both sides are respectively equipped with trolleys 1 . The workbench includes two bottom beams extending longitudinally, a bottom plate sealed and fixed to the bottom surfaces of the two bottom beams, an end plate sealed and fixed to the two ends of the two bottom beams, and a top plate located on the top surface of the two bottom beams, the bottom beam, the bottom plate , the end plate and the top plate encircle an exhaust gas collection box 11, and the exhaust gas collection box 11 is connected to the induced draft fan. The top plate on the side is provided with folds, and the air inlet is provided with a rigid rod fixedly connected with the trolley. The two main rails are located outside the two bottom beams and are fixedly connected with ...

Embodiment 2

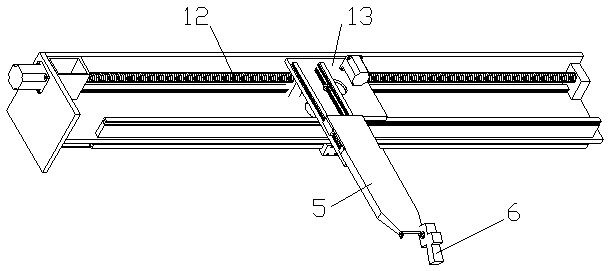

[0045] The difference between this embodiment and Embodiment 1 is that the power mechanism includes two pulleys that are axially connected to the cross bar, and an endless toothed belt connecting the two pulleys, wherein one pulley is connected with a reciprocating motor fixed on the cross bar , the second slider is fixedly connected to the toothed belt. In order to reduce friction, the wheel shafts of the two pulleys are connected with the cross bar through bearings, and the wheel surfaces of the pulleys are provided with teeth meshed with the toothed belt. The positive and negative rotation of the reciprocating motor drives the pulley to rotate, thereby driving the toothed belt to rotate back and forth, and finally makes the second slider move back and forth. This structure reduces the weight of the equipment, and the movement of the second slider is more flexible, and the production, use and maintenance costs are lower. lower.

[0046] The workbench of this embodiment is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com