Suspension type ultrasonic cleaning line

An ultrasonic cleaning and hanging technology, which is applied to fixed filter elements, household components, applications, etc., can solve the problems of increasing cleaning costs, cleaning liquid consumption time, and affecting cleaning efficiency, so as to reduce cleaning costs and reduce spraying Cost, the effect of ensuring cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

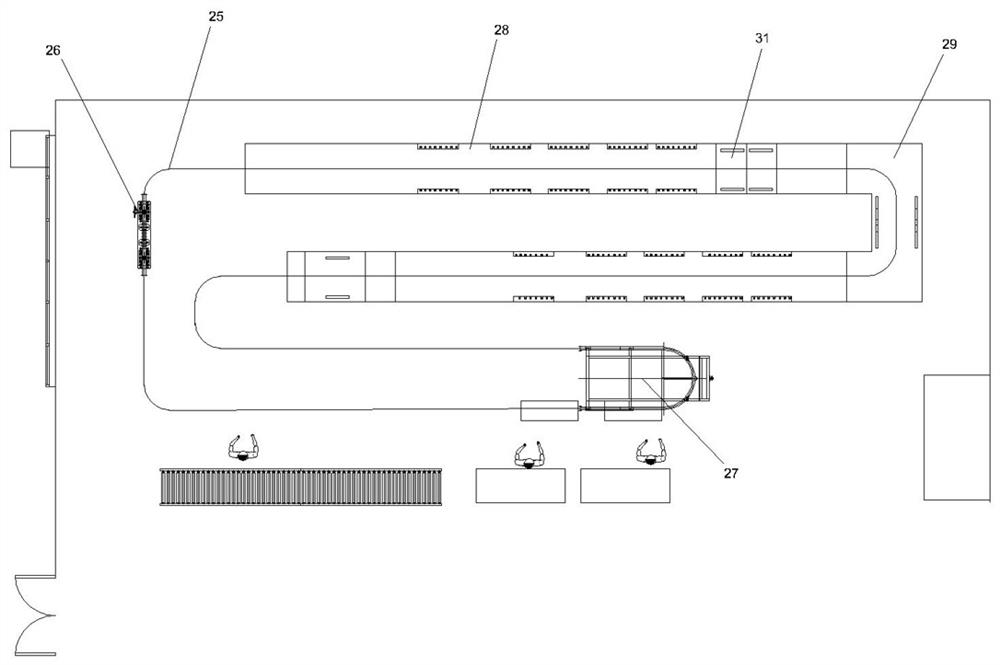

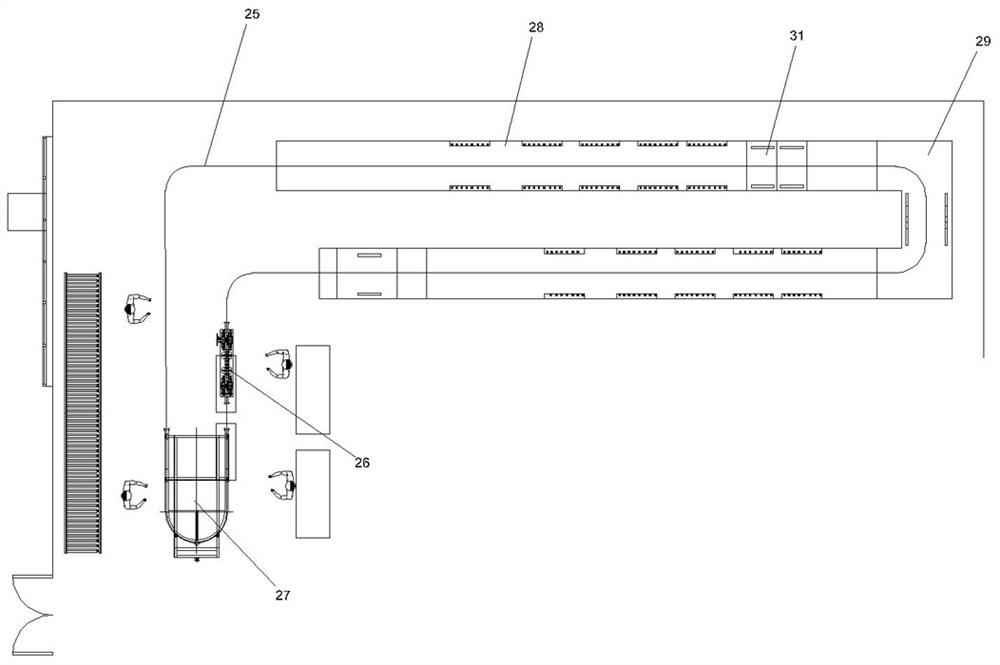

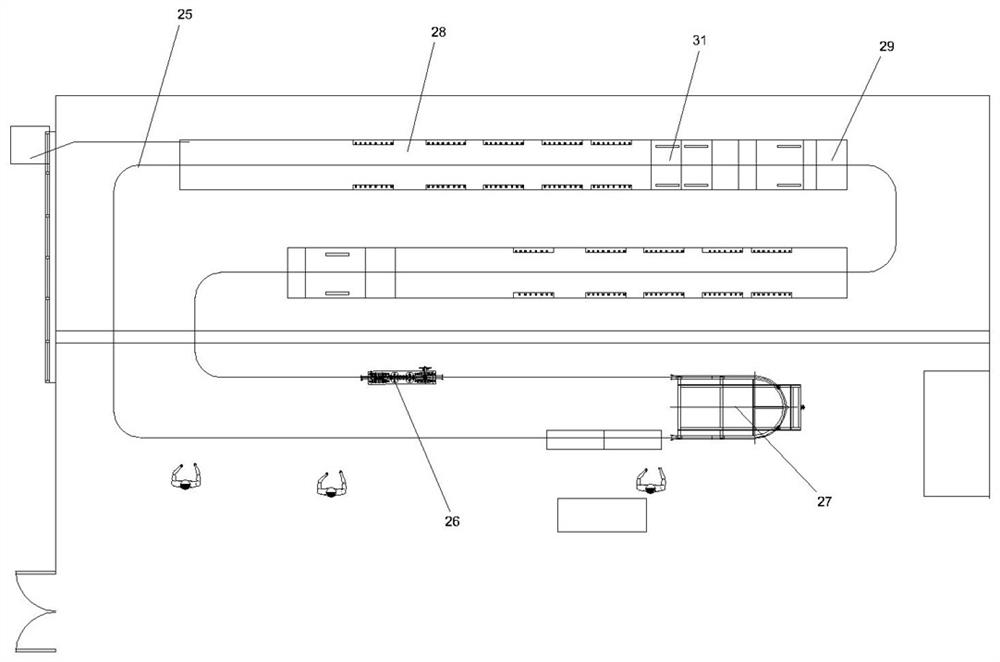

[0041] Such as Figure 1-15 Shown, a kind of suspension type ultrasonic cleaning line, comprises suspension type conveyer belt 25, is positioned at the driving seat 26 on the suspension type conveyer belt 25, tensioning device 27 and some hand mold cleaning baskets 30 and is positioned at the suspension type conveyer belt 25 below Two ultrasonic cleaning tanks 28 and two municipal water spraying devices 29, the former ultrasonic cleaning tank is provided with a spray cleaning structure 31, the ultrasonic cleaning tank 28 includes a main tank body 1, and auxiliary tanks connected at both ends of the main tank body 1 body, 10 ultrasonic vibration boxes 2 installed on both sides of the main tank body 1, the main tank body overflow port 3 located on the main tank body 1 and the main ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com