Ultra-large-diameter tube section shell and cross beam high-precision sleeving tool

A technology of ultra-large diameter and well-shaped beams, which is applied in the field of component assembly, can solve the problems of failure to install and damage the shell of the barrel section, and achieve the effects of reducing shell deformation, ensuring shape and size, and high-precision assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

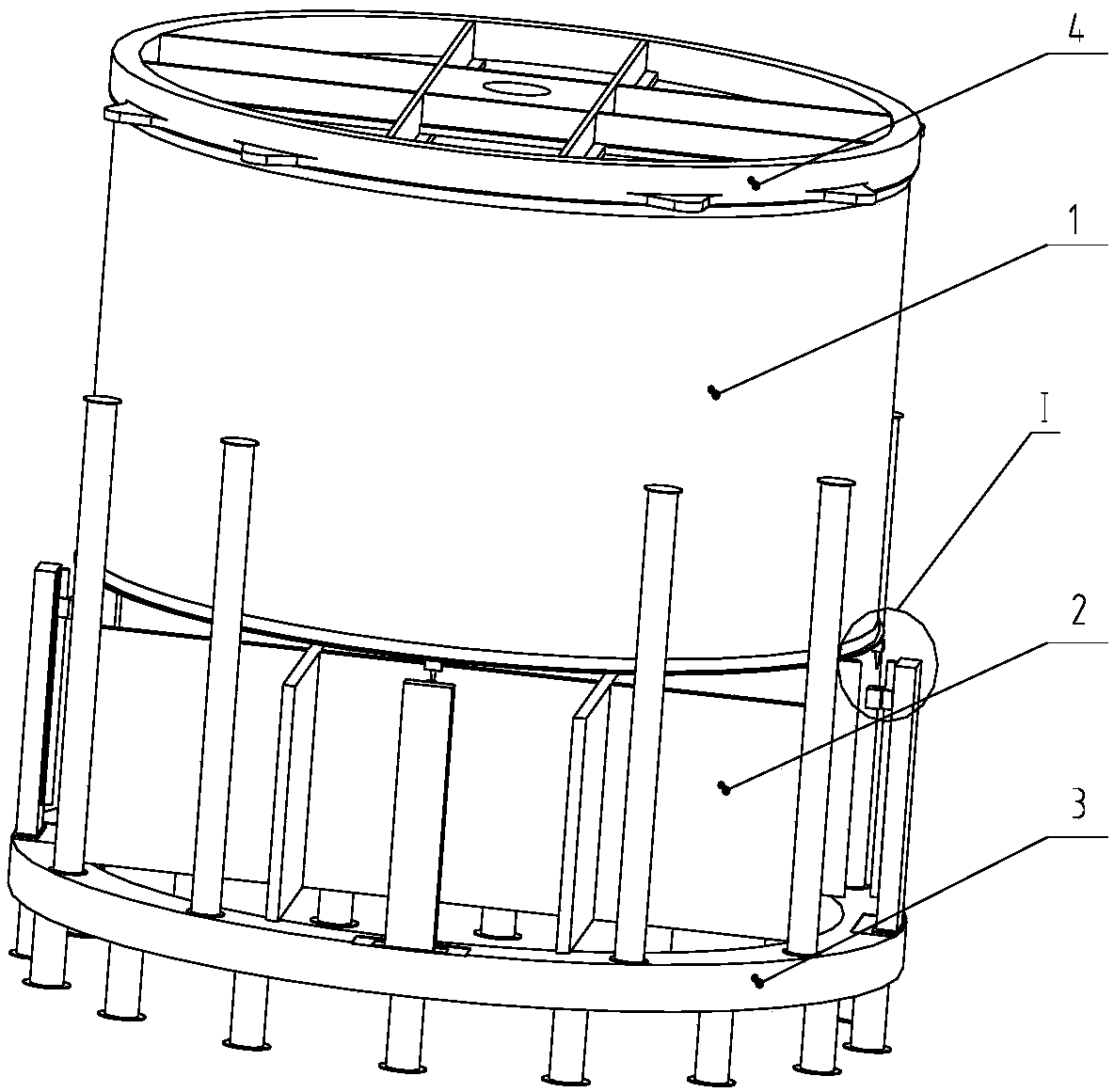

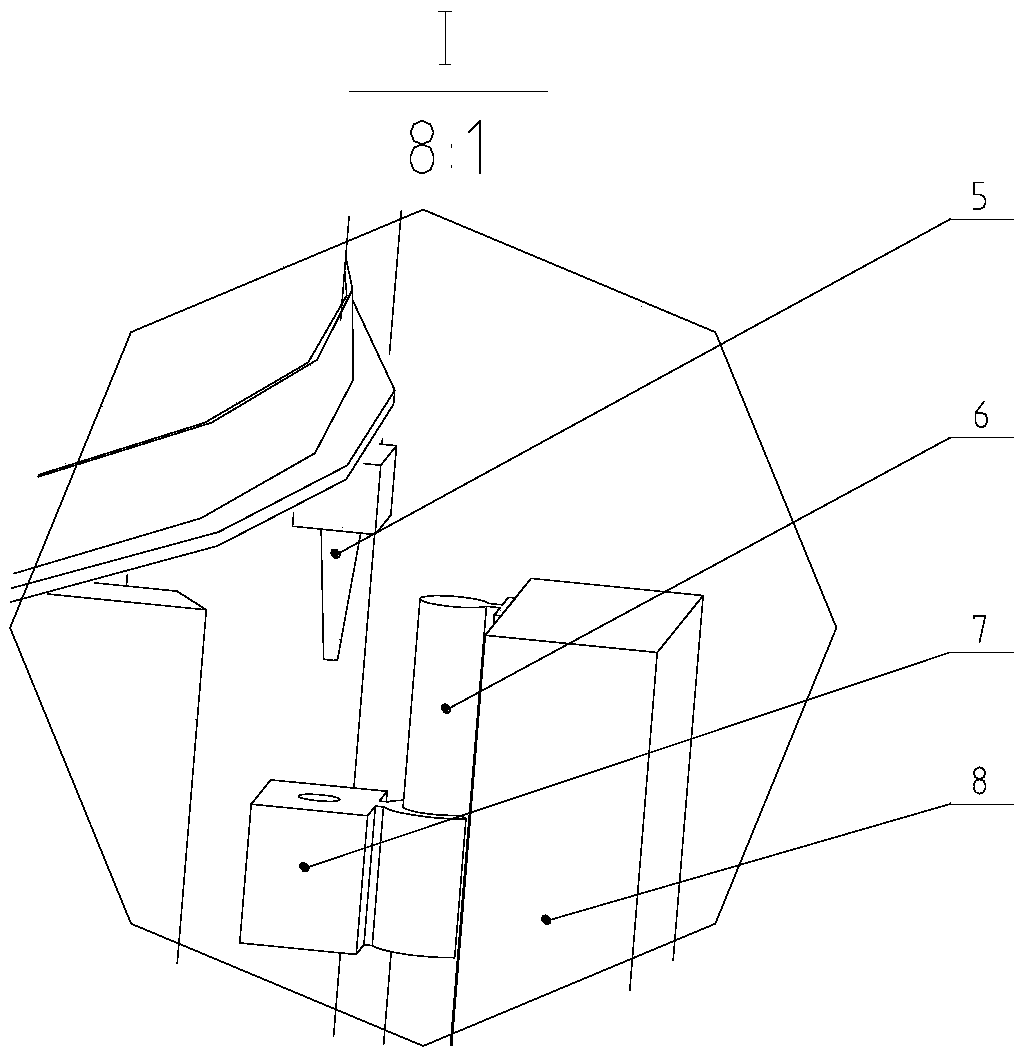

[0026] Such as figure 1 Shown is a high-precision set tool for a super-large-diameter barrel section shell and a well-shaped beam, which is used to assemble the barrel section shell 1 and the well-shaped beam 2 of the first-stage transition section of a heavy-duty launch vehicle. The barrel section shell 1 is a cylindrical shell formed by connecting skin, girders and end frames with rivets and screws, and the well-shaped beam 2 is a well-shaped structural member welded by steel plates. The inner diameter of the barrel section shell 1 is 9500 mm, and the well-shaped beam 2 can be matched inside the barrel section shell 1 . A jig upper cover 4 is provided above the barrel casing 1 for supporting the barrel casing 1, enhancing the strength of the barrel casing 1, and facilitating high-precision assembly.

[0027] The well-shaped beam 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com