System and method for light beam shaping welding

A beam shaping and welding system technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as inability to realize automatic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

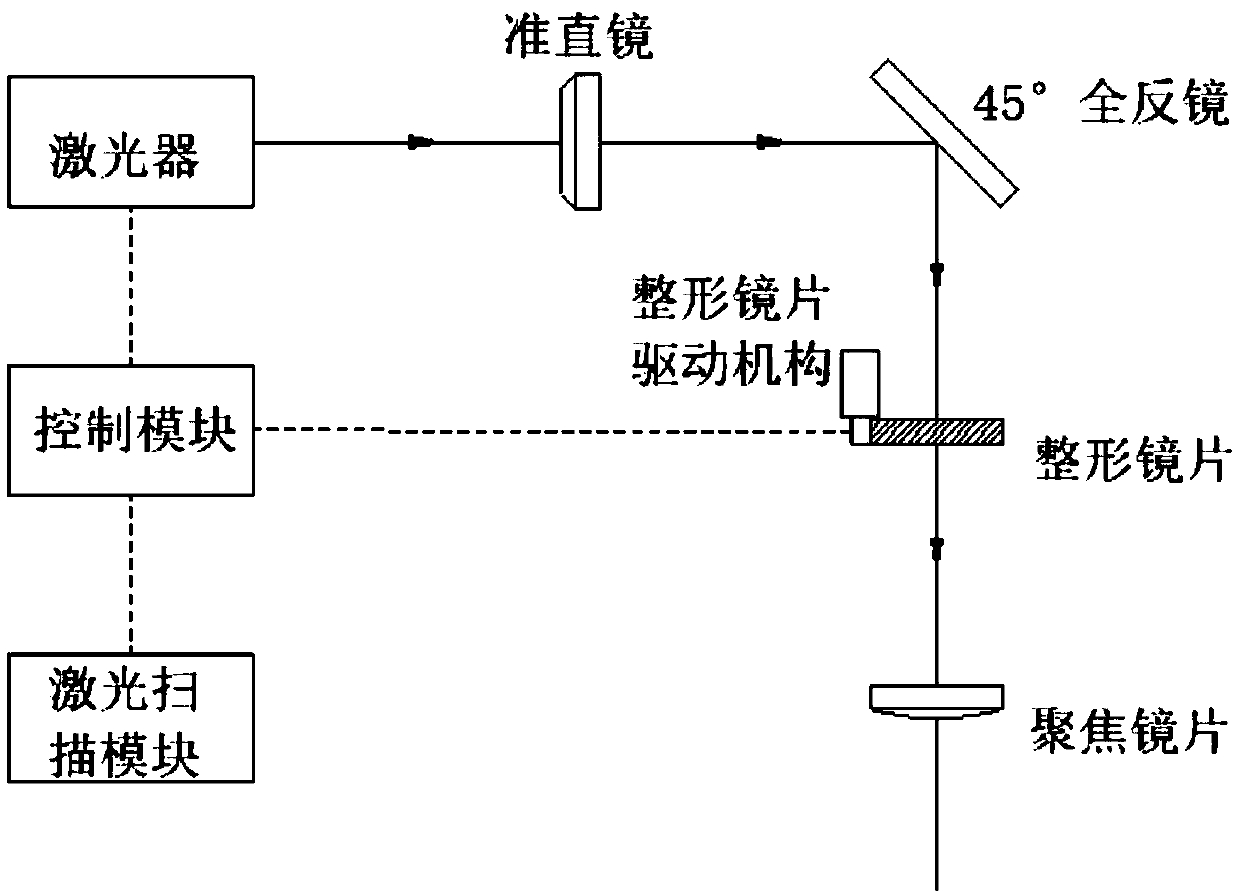

[0031] This embodiment provides a beam shaping welding system, such as figure 1 As shown, including laser, collimating mirror and 45° total reflection mirror, also includes:

[0032] Laser scanning module, used to scan the welding path;

[0033] A control module electrically connected to the laser scanning module, used to control the welding head to perform welding;

[0034] A solder joint electrically connected to the control module.

[0035] Specifically, in this embodiment, the laser scanning module is a laser scanner, and the laser scanner uses a rapidly oscillating (or rotating) mirror to emit a laser beam with highly concentrated energy, so that the output angle of the laser beam increases with the emission angle. The movement of the mirror produces continuous changes, thus projecting a scanning line. Although the laser scanner has only one photodetector and one light source, due to the high scanning frequency of the mirror, the laser scanner can obtain image informati...

Embodiment 2

[0046] Compared with Embodiment 1, this embodiment provides a welding example of a curved path, and the rest are the same as Embodiment 1, and the same parts will not be repeated here.

[0047] The working process of the curved path welding example provided in this embodiment is:

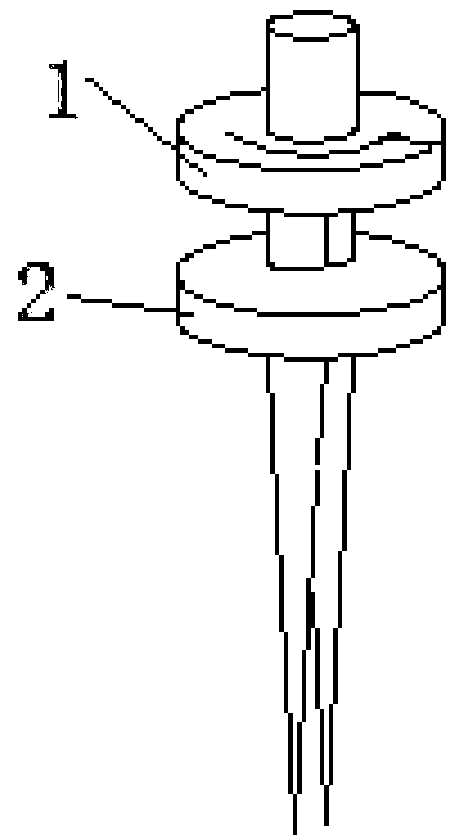

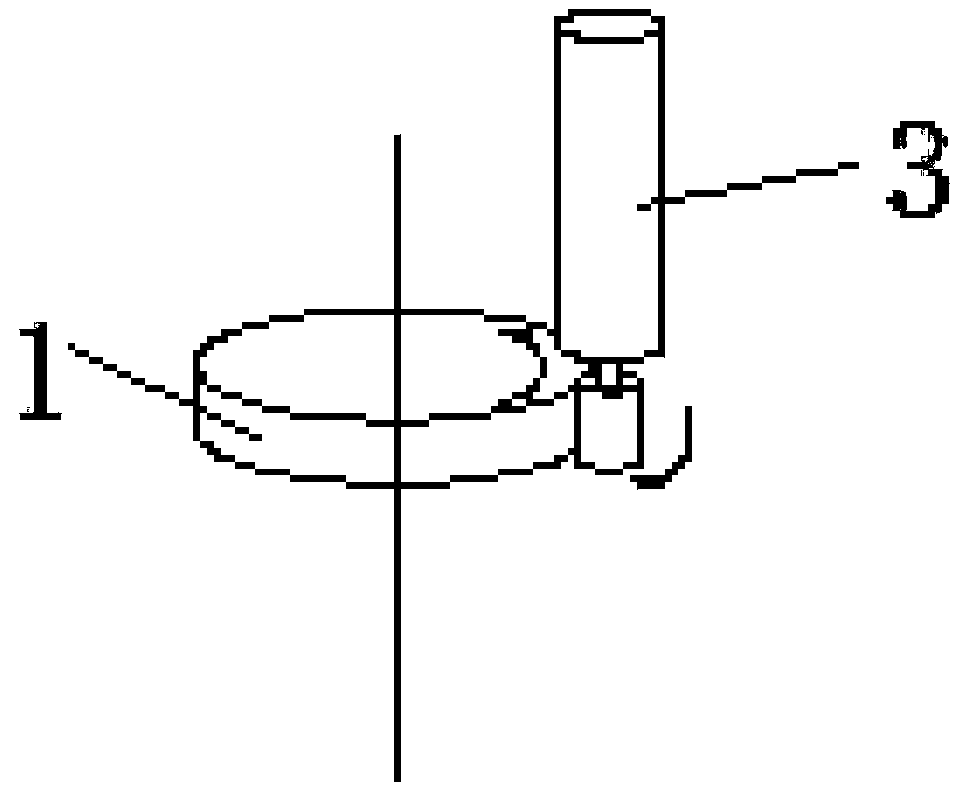

[0048] Such as Figure 6As shown, the welding operation starts from the starting point, and the long axis of the light spot is kept perpendicular to the welding path (or the angle required by the process) and moves along the predetermined path. During the welding process, the control module controls the direction and rotation angle of the plastic lens 1 to adjust in real time according to the path direction , so as to obtain the weld seam shown in the picture, complete the welding of the picture path, and the rotation angle of the plastic lens is 0-90°; thus, the welding of the curved path is completed. The figure is a plane curve, if it is a space curve, it can also be realized with the Z-directio...

Embodiment 3

[0050] Compared with Embodiment 1, this embodiment provides an example of welding with an elliptical path, and the rest are the same as Embodiment 1, and the same parts will not be repeated here.

[0051] The working process of the elliptical path welding example provided by this embodiment is:

[0052] Such as Figure 7 As shown, the welding operation can be started at any point on the path shown in the figure. The control module controls the rotation angle of the plastic lens 1 to make real-time adjustments according to the welding path. After completing the welding operation of the entire elliptical path, the rotation angle of the plastic lens is 0-360 °, thus completing the welding of the elliptical path.

[0053] It should be noted that the present invention can meet the welding operation of complex spatial curve paths, and is not limited to the welding of rectangular paths, curved paths and elliptical paths, and the weld seam properties are highly consistent throughout ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com