Rolling and bulging composite forming method of high temperature alloy ring piece

A composite forming and superalloy technology, applied in the field of superalloy ring rolling and bulging composite forming, can solve the problems of poor performance, low precision and low material utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

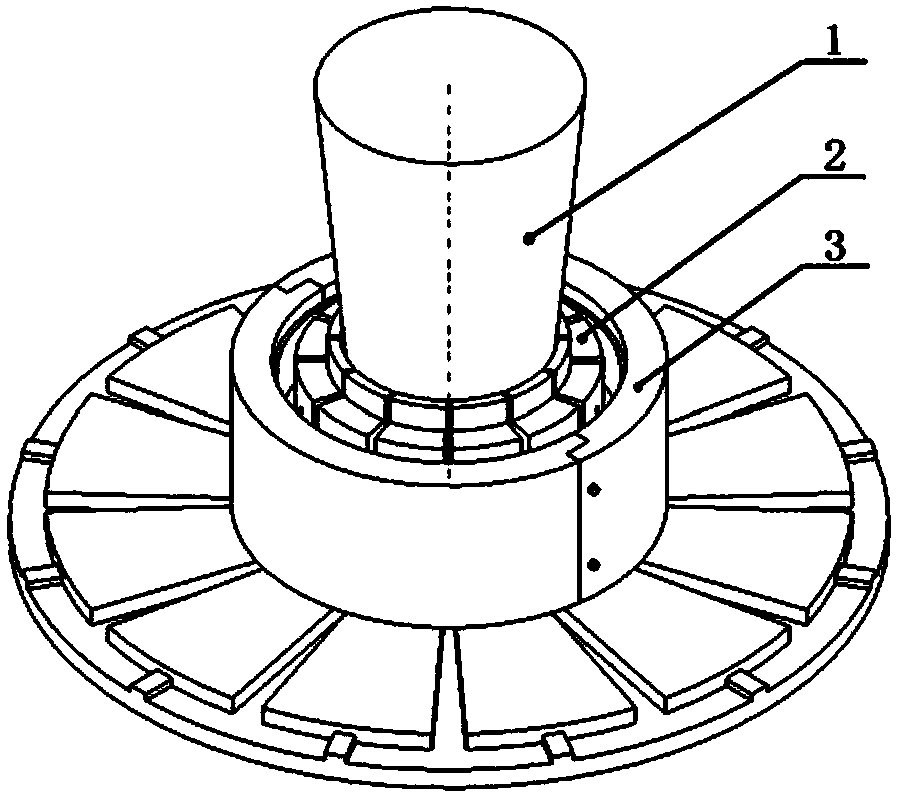

Image

Examples

specific Embodiment approach

[0029] The main chemical element content (percentage by weight) of the alloy is: C content ≤ 0.08%, Cr content 17.0% ~ 21.0%, Ni content 50.0% ~ 55.0%, Co content ≤ 1.0%, Mo content 2.80% ~ 3.30%, Al content 0.30% ~ 0.70%, Ti content 0.75% ~ 1.15%, Nb content 4.75% ~ 5.50%, B content ≤ 0.006%, Mg content ≤ 0.01%, Mn content ≤ 0.35 %, Si content≤0.35%, P content≤0.015%, S content≤0.015%, Cu content≤0.30%, Ca content≤0.01%, Pb content≤0.0005%, Se content≤0.0003% , The balance is Fe.

[0030] The steps of this method are as follows:

[0031] The first step: determine the outer diameter R of the bulging blank Z , Inner diameter of bulging blank r z , Height of bulging blank h z , initial rough inner diameter r 0 , the initial blank axial height h 0 and the initial rough outer diameter R 0 ;

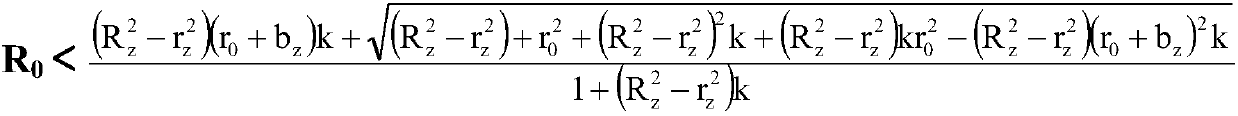

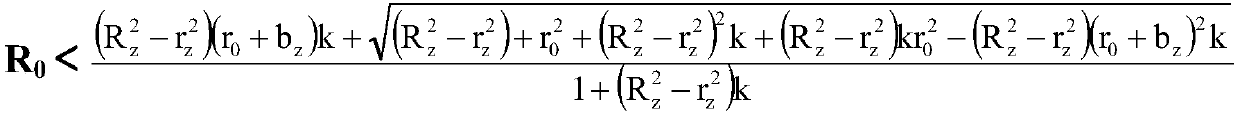

[0032] Calculate the blank of the bulging process according to the size of the ring without finishing, and the wall thickness of the ring without finishing is b f , the minimum outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com