Device for adding balls to flower drum body

A ball and hub technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome operation and low work efficiency, and achieve the effect of simplifying operation procedures, saving human capital, and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

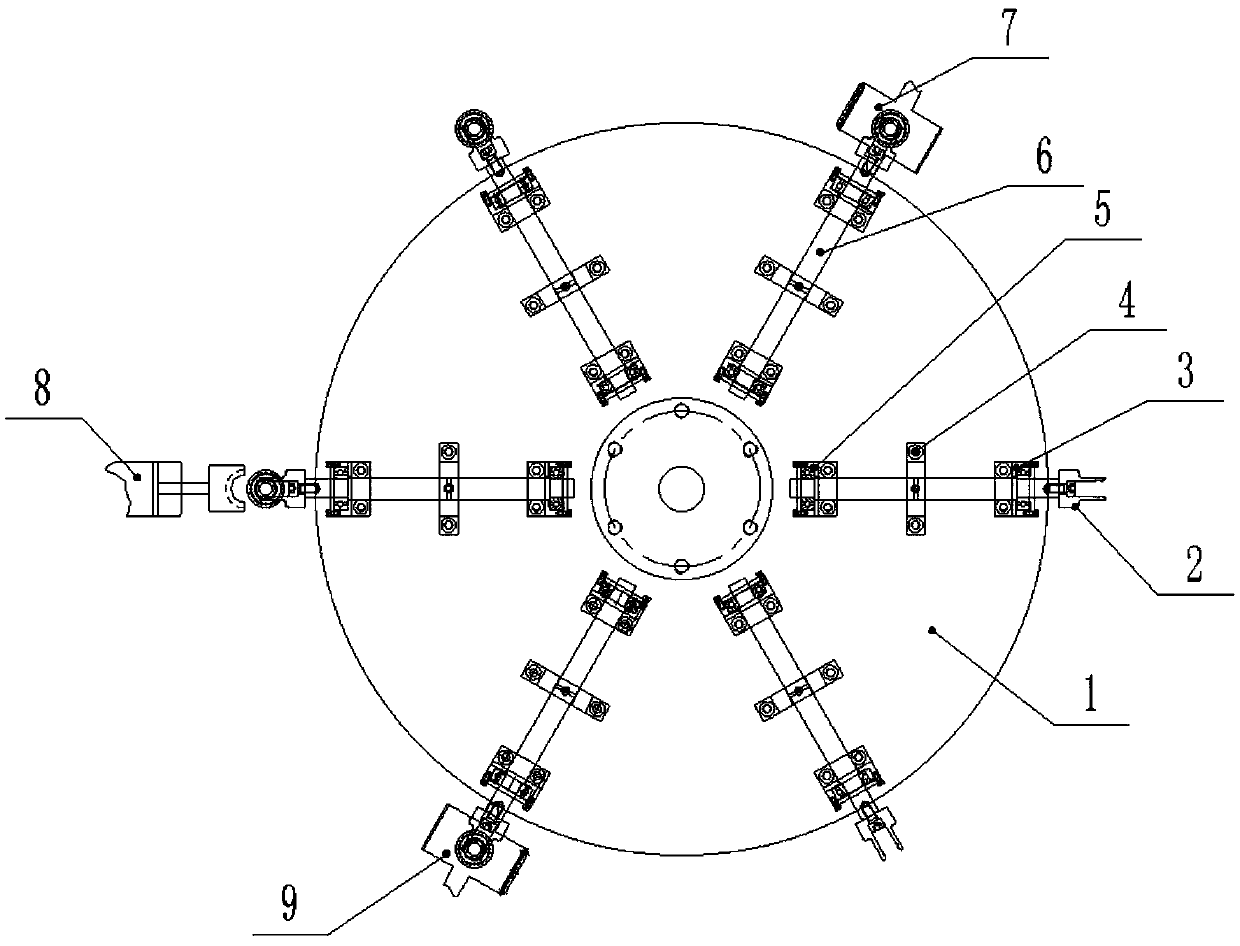

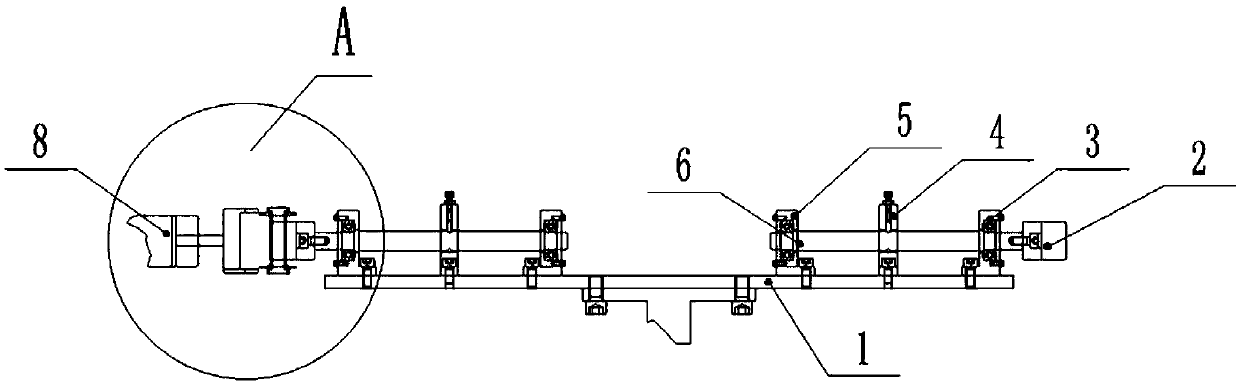

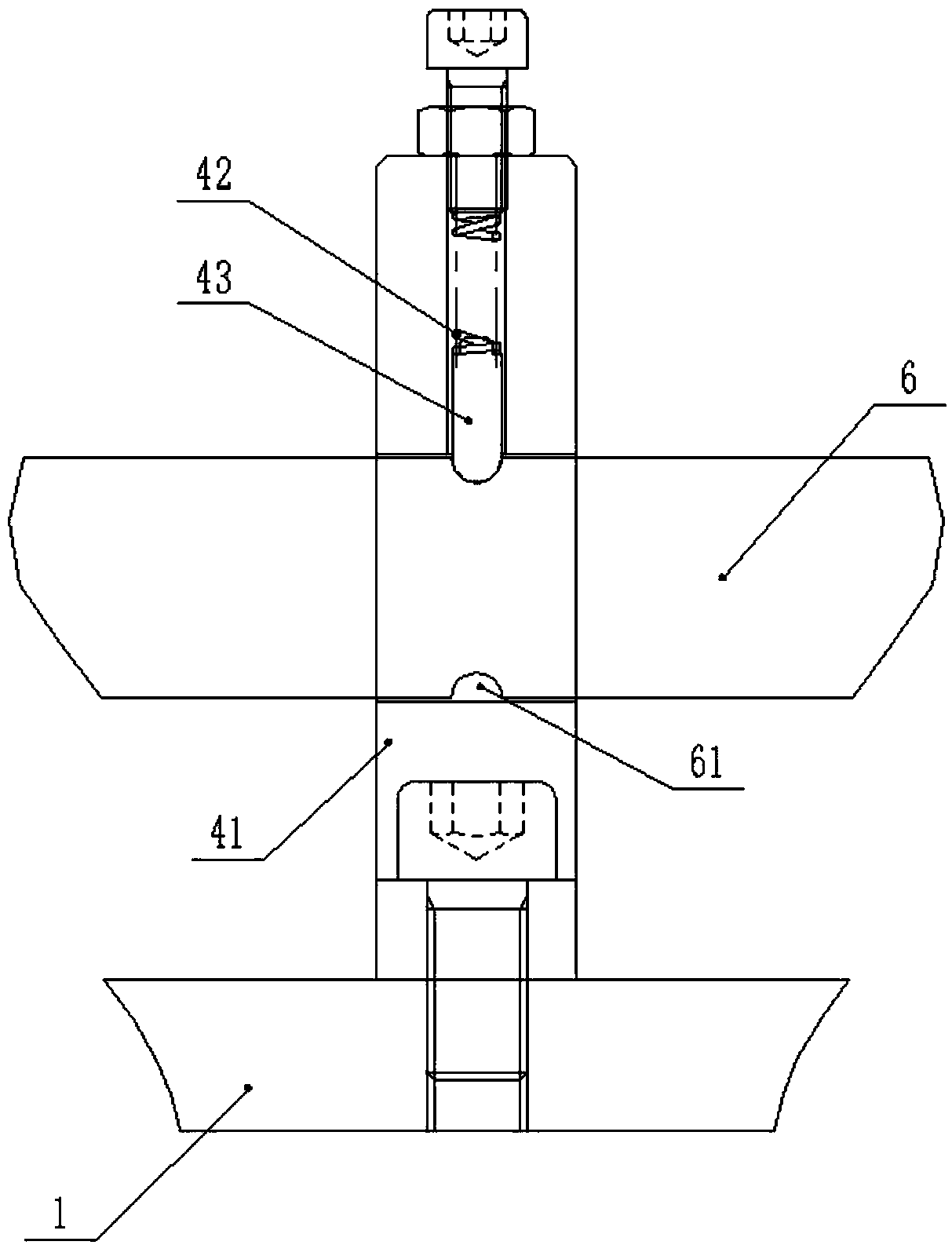

[0029] Such as figure 1 , figure 2 As shown, a device for adding balls to a hub body according to an embodiment of the present invention includes a turntable 1, and the lower part of the turntable 1 is connected to a cam divider through a flange, and the cam divider drives the turntable 1 to rotate counterclockwise. The ratio is 1:1. The inner ring of the turntable 1 is equipped with an inner shaft seat 5, and the outer circumference of the turntable 1 is equipped with an outer shaft seat 3. The positions of the inner shaft seat 5 and the outer shaft seat 3 correspond one by one, including the The long axis 6 is positioned by the inner shaft seat 5 and the outer shaft seat 3 to form a free rolling structure, and the middle part of the long axis 6 is processed with two upper and lower counterbores 61, and the counterbores 61 are symmetrically distributed on the circumference (see image 3 ), the major axis 6 passes through the center of the turntable 1, the clamp block 2 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com