Stand column section bar grinding and fixing process device

A technology of process equipment and profiles, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of waste of labor, low efficiency, and increased time, and achieve the effects of improving work efficiency, convenient operation, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

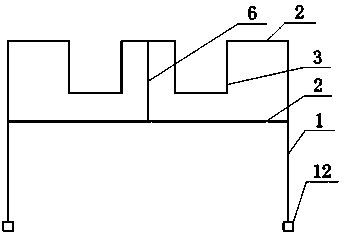

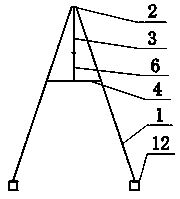

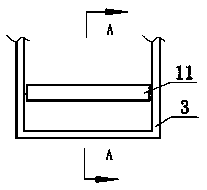

[0022] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , in the figure, 1-support, 2-crosspiece, 3-rectangular groove, 4-reinforcing rib, 5-reinforced crossbar, 6-auxiliary support, 7-bolt, 8-baffle, 9-bar hole, 10-auxiliary reinforcing plate, 11-triangular rotating shaft, 12-pulley, 13-nut.

[0023] The column profile grinding and fixing process device includes a bracket. The bracket includes a support 1 and a crosspiece 2. The support 1 is a triangular structure, and the crosspiece 2 is arranged between the two supports 1. There are two brackets on the crosspiece 2 for placing the column The rectangular groove 3 of the profile, the support 1 is provided with a reinforcing rib 4, and a reinforcing cross bar 5 is arranged between the reinforcing ribs 4, and the cross member 2 arranged between the two rectangular grooves 3 passes through the auxiliary support 6 and the reinforcing cross bar 5 connections.

[0024] Further, the crosspiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com