Concave block sorting equipment

A concave and equipment technology, applied in the direction of conveyors, packaging, conveyor objects, etc., can solve the problem that the workload of concave blocks cannot be automatically transformed, and achieve the effect of protection against wear and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

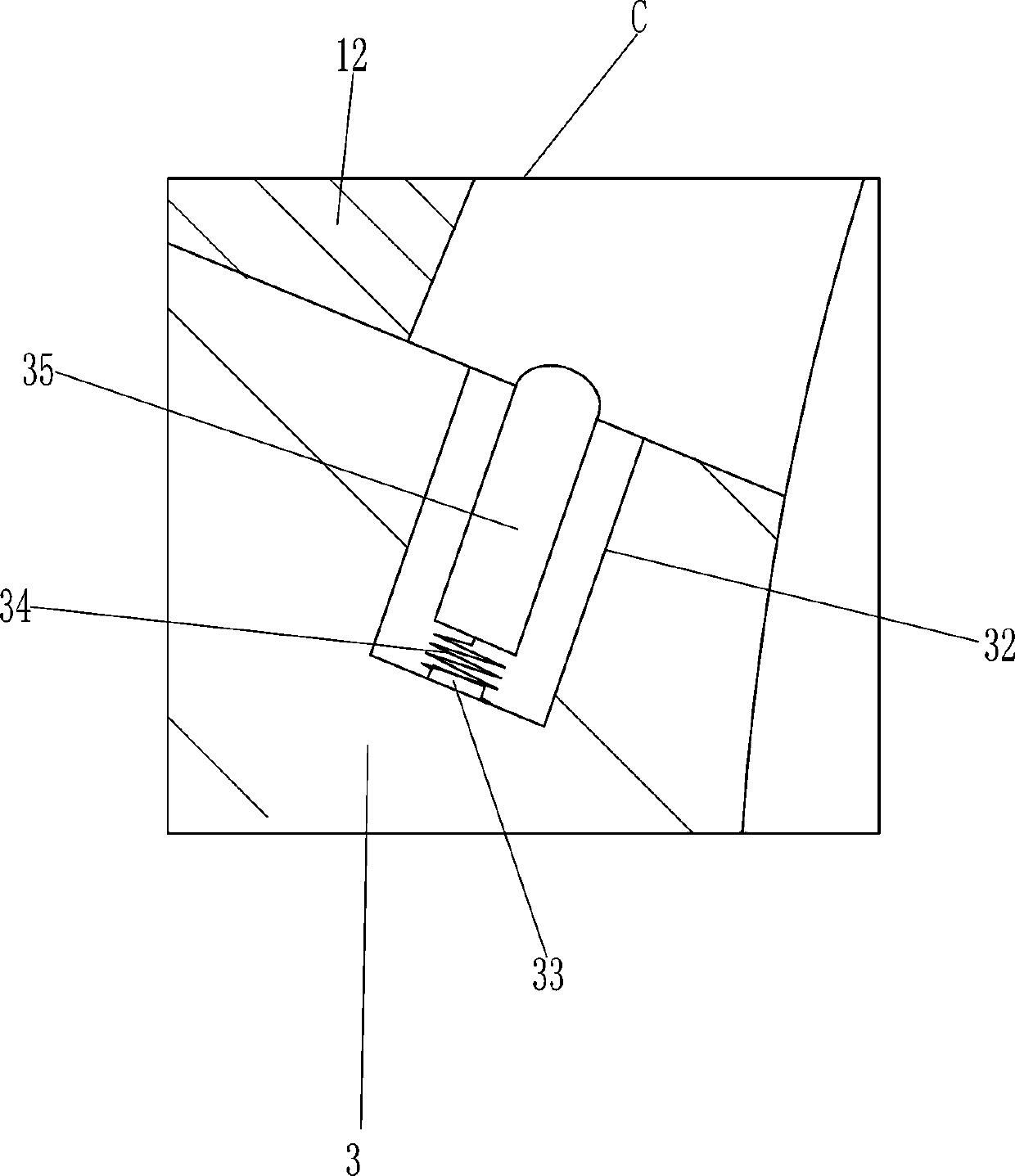

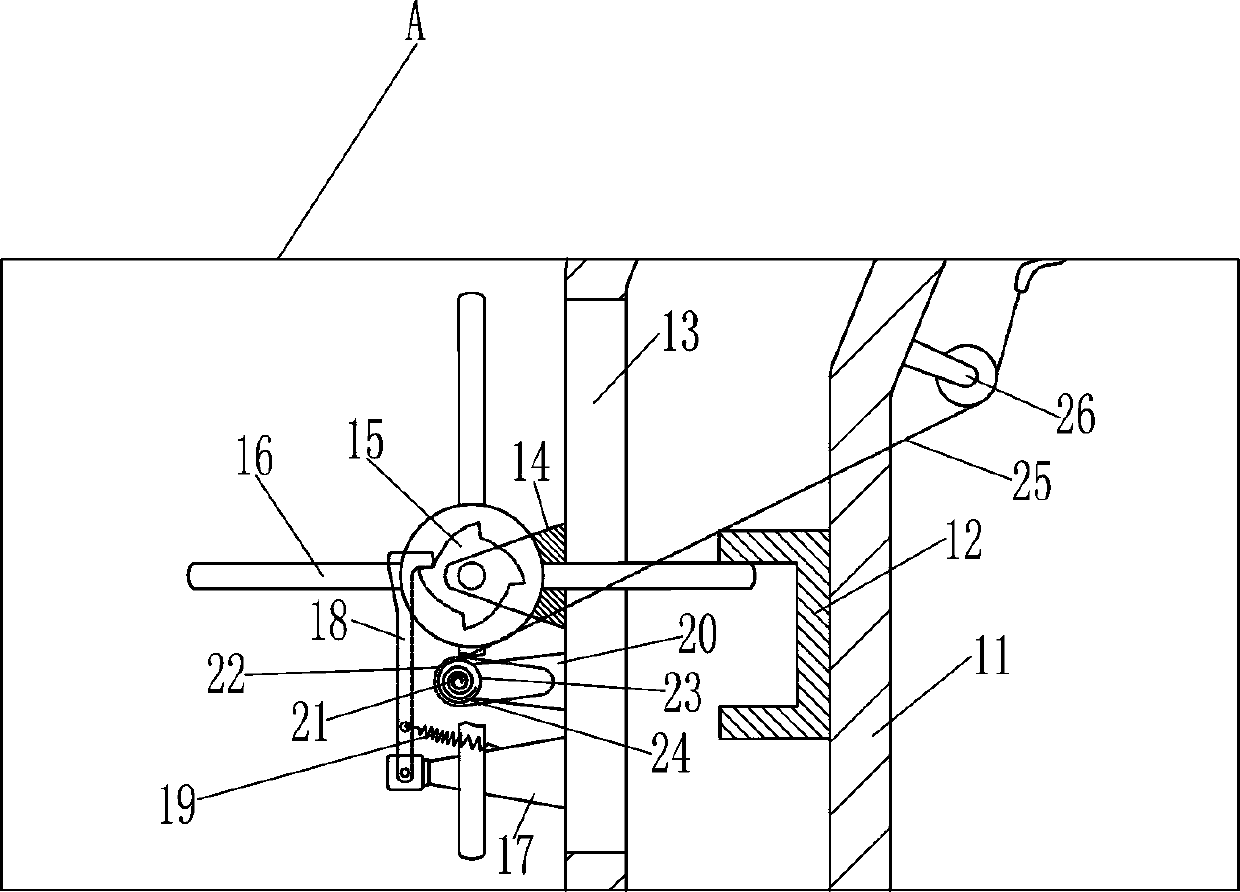

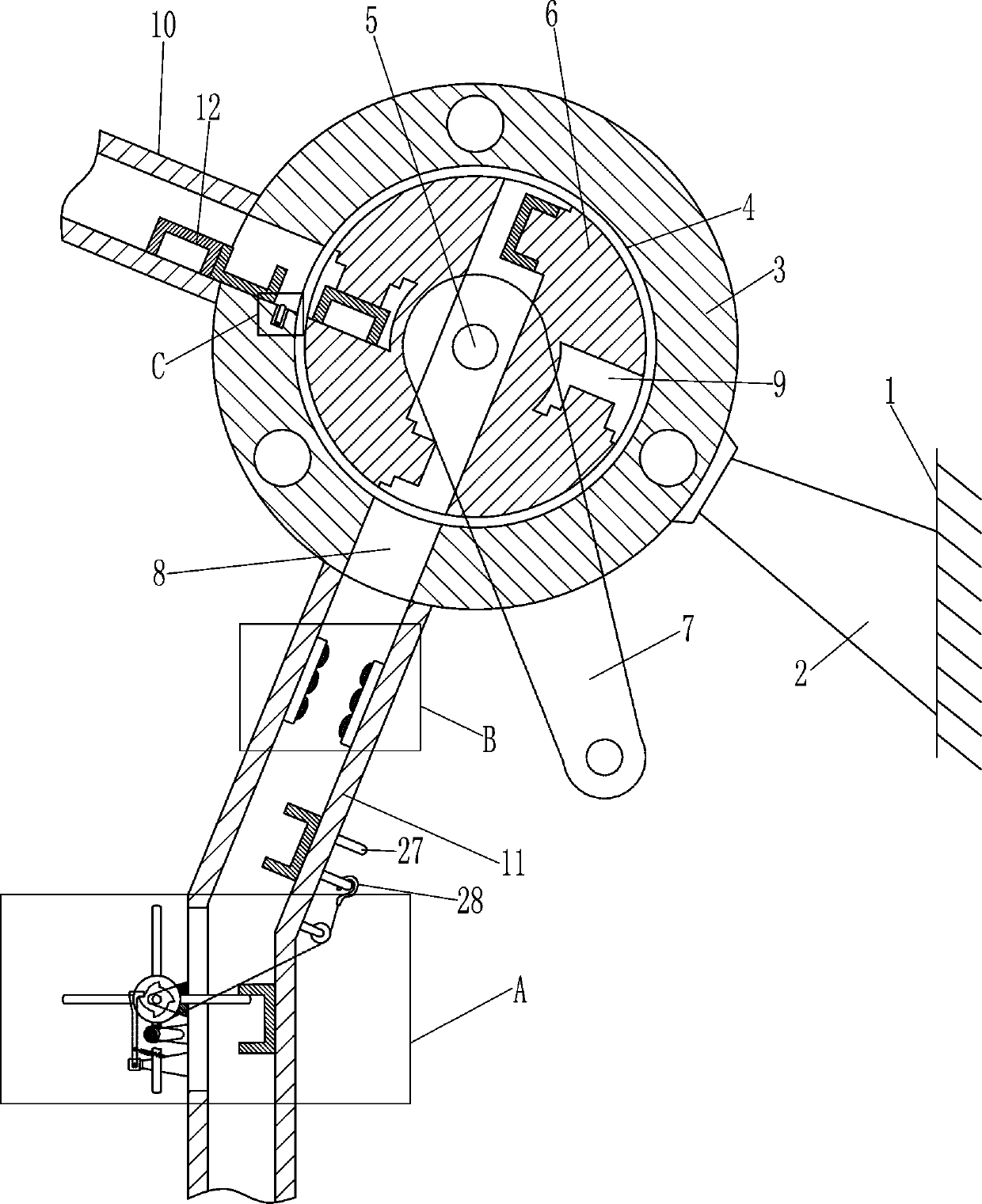

[0020] A concave block sorting equipment such as Figure 1-4 As shown, it includes a pole 2, a mounting frame 3, a first rotating shaft 5, a concave block turntable 6, a turning handle 7, a first groove plate 10, a second groove plate 11, a first bearing seat 14, a ratchet 15, a cross Wheel 16, first mount 17, ratchet bar 18 and first back-moving spring 19, wall surface 1 left side is provided with pole 2, pole 2 is provided with mounting frame 3, and the middle part of mounting frame 3 has first concave Groove 4, the installation frame 3 center rotation type is connected with the first rotating shaft 5, the front side of the first rotating shaft 5 is provided with concave block turntable 6, concave block turntable 6 is located in the first groove 4, the first rotating shaft 5 rear side is provided with Turning handle 7 is arranged, and turning handle 7 is positioned at the rear side of installation frame 3, and the middle part of concave block turntable 6, the left part and t...

Embodiment 2

[0022] A concave block sorting equipment such as Figure 1-4As shown, it includes a pole 2, a mounting frame 3, a first rotating shaft 5, a concave block turntable 6, a turning handle 7, a first groove plate 10, a second groove plate 11, a first bearing seat 14, a ratchet 15, a cross Wheel 16, first mount 17, ratchet bar 18 and first back-moving spring 19, wall surface 1 left side is provided with pole 2, pole 2 is provided with mounting frame 3, and the middle part of mounting frame 3 has first concave Groove 4, the installation frame 3 center rotation type is connected with the first rotating shaft 5, the front side of the first rotating shaft 5 is provided with concave block turntable 6, concave block turntable 6 is located in the first groove 4, the first rotating shaft 5 rear side is provided with Turning handle 7 is arranged, and turning handle 7 is positioned at the rear side of installation frame 3, and the middle part of concave block turntable 6, the left part and th...

Embodiment 3

[0025] A concave block sorting equipment such as Figure 1-4 As shown, it includes a pole 2, a mounting frame 3, a first rotating shaft 5, a concave block turntable 6, a turning handle 7, a first groove plate 10, a second groove plate 11, a first bearing seat 14, a ratchet 15, a cross Wheel 16, first mount 17, ratchet bar 18 and first back-moving spring 19, wall surface 1 left side is provided with pole 2, pole 2 is provided with mounting frame 3, and the middle part of mounting frame 3 has first concave Groove 4, the installation frame 3 center rotation type is connected with the first rotating shaft 5, the front side of the first rotating shaft 5 is provided with concave block turntable 6, concave block turntable 6 is located in the first groove 4, the first rotating shaft 5 rear side is provided with Turning handle 7 is arranged, and turning handle 7 is positioned at the rear side of installation frame 3, and the middle part of concave block turntable 6, the left part and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com